Manitowoc Published 05-26-17, Control # 238-02 7-11

MLC165-1 SERVICE/MAINTENANCE MANUAL POWER TRAIN

ENGINE RADIATOR

Checking Coolant Level

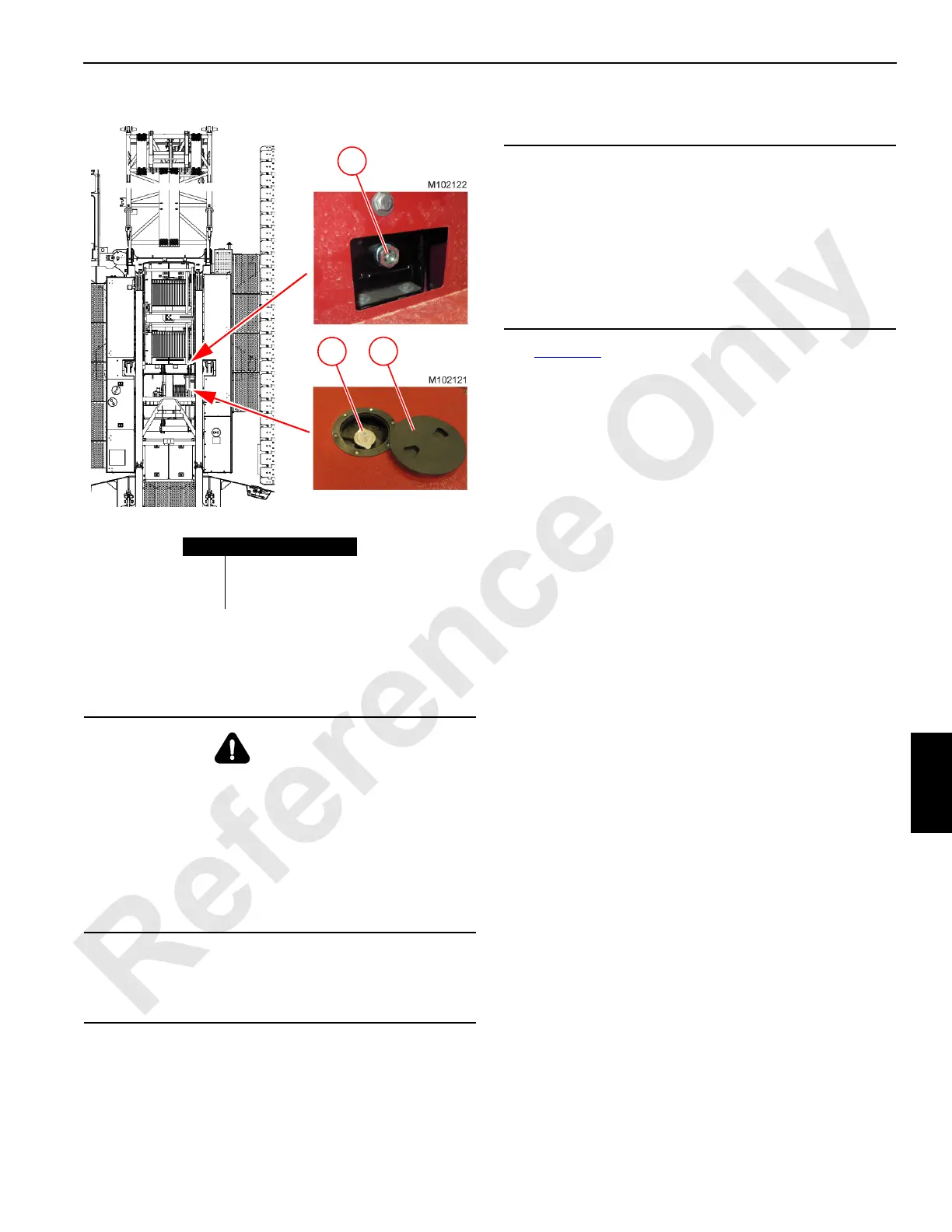

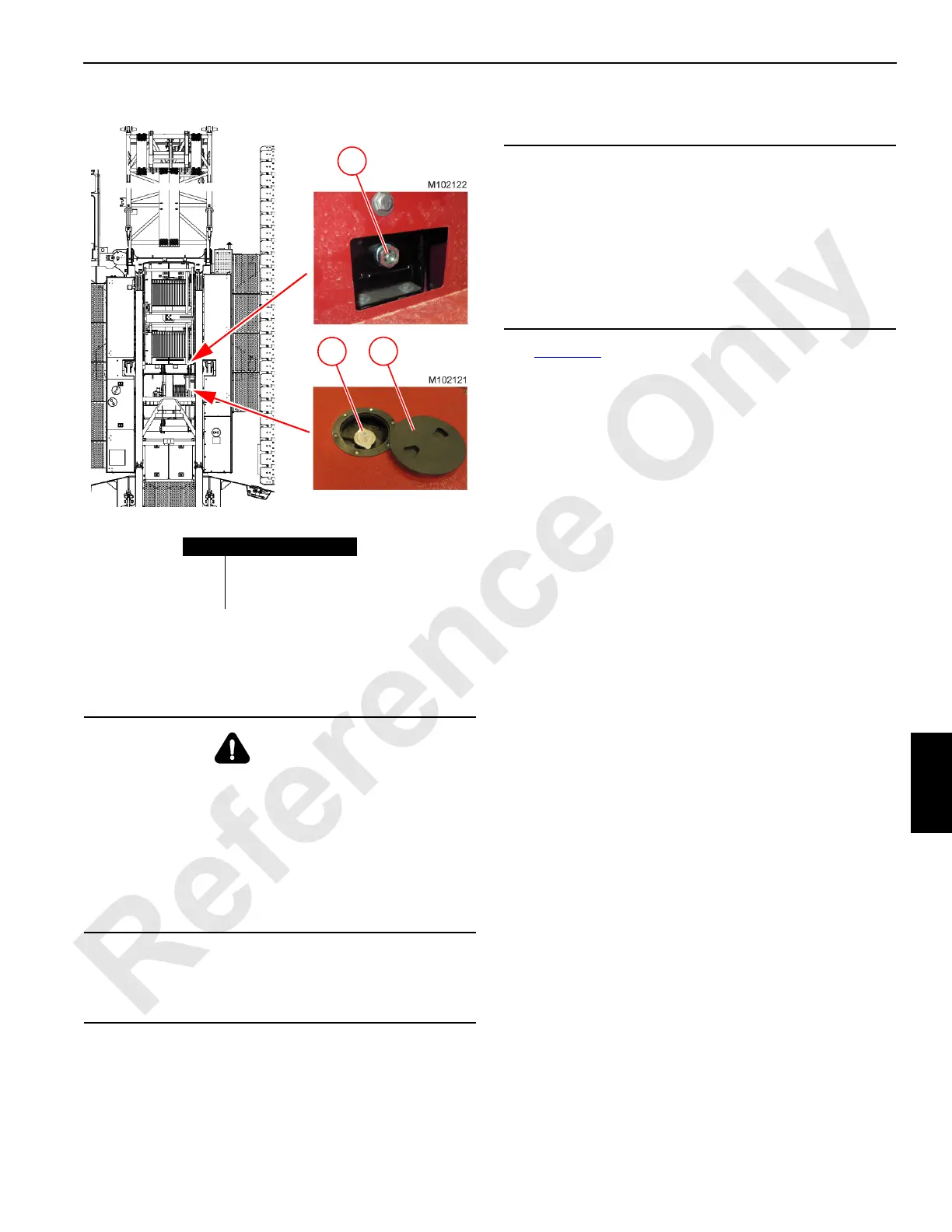

See Figure 7-9 for the following procedure.

Refer to the engine manufacturer’s manual for additional

cooling system maintenance instructions.

Check the coolant level every 8 hours of operation or daily

(whichever occurs first) when the coolant is cold.

The coolant should be at the full cold mark on the decal next

to the sight glass (1). Add coolant, as needed.

1. Remove the access cover (2).

2. Place a heavy dry cloth over the fill cap (3), then turn (do

not depress) the fill cap until it stops at the safety detent.

3. Wait for the pressure to escape.

4. When the hissing stops, depress the cap, and turn it

clockwise to remove.

5. Add coolant to the radiator. Stop several times to allow

the coolant to flow into the engine and all portions of the

radiator.

6. When the coolant is at the proper level in the sight glass,

install the fill cap.

7. Run the engine until the normal operating temperature is

reached.

8. When the engine is cool again, re-check the coolant

level as described above. If needed, add coolant until it

is at the proper level.

9. Install the fill cap and access cover.

WARNING

Burn Hazard

Do not remove the radiator fill cap from a hot engine.

Allow the engine to cool below 120° F (50° C) before

adding the coolant.

Material Hazard

Coolant is toxic. Do not ingest. If not reused, dispose in

accordance with all local and other applicable

environmental regulations.

CAUTION

Avoid Engine Damage

The required coolant level must be maintained to prevent

engine damage.

Figure 7-9. Radiator Level and Fill

Item Description

1 Level Sight Glass

2 Access Cover

3 Fill Cap

1

3

2

CAUTION

Maintain Coolant Additive

The required Supplemental Coolant Additive (SCA)

concentration must be maintained to prevent engine

damage.

Check the SCA concentration according to the schedule

in the engine manufacturer’s manual and per the

manufacturer’s warnings, cautions, and instructions.

Loading...

Loading...