HOISTS MLC165-1 SERVICE/MAINTENANCE MANUAL

5-46

Published 05-26-17, Control # 238-02

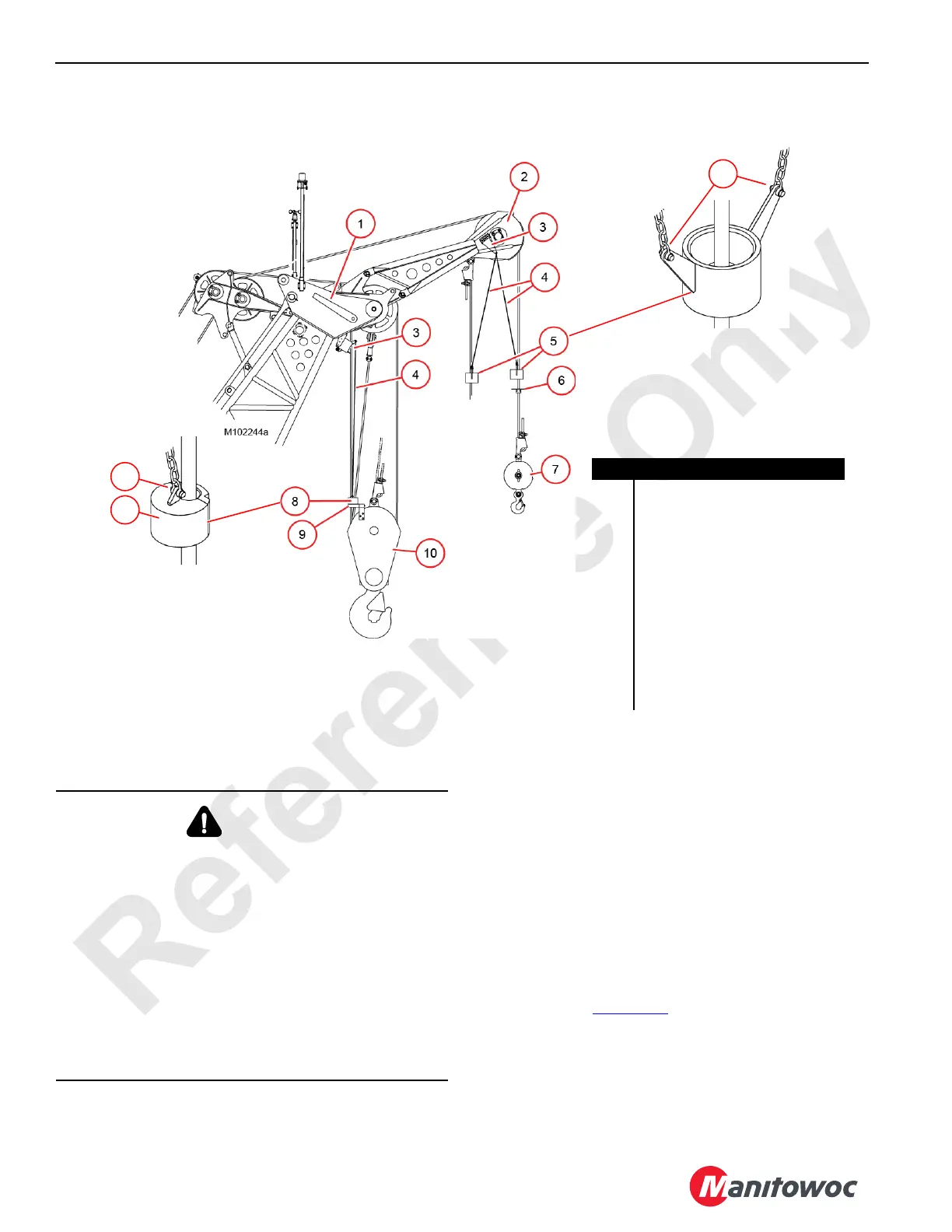

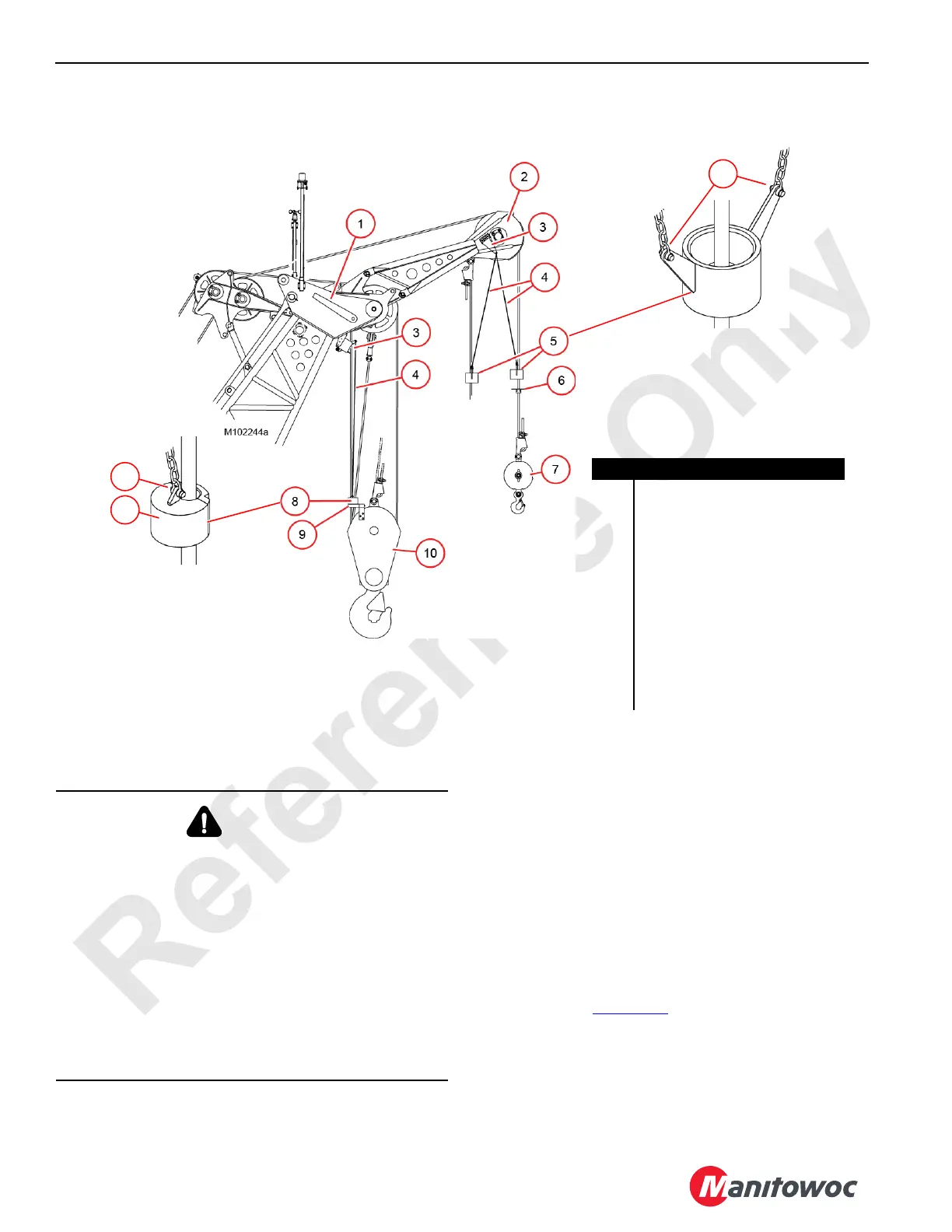

BLOCK-UP LIMIT SWITCH

A block-up limit (also called anti-two-block device) is a two-

blocking prevention device that stops the load drum from

hoisting and the boom (or luffing jib) from lowering when a

block or hook is too close to the sheave.

NOTE The block-up limit is a protective device designed

only to assist the operator in preventing a two-

blocking condition. Any other use is neither

intended nor approved.

The block-up limit system consists of the following

components (see Figure 5-32

):

• A limit switch (3), wired for normally closed operation,

fastened at the lower boom point (1) and the upper

boom point (2).

• Upper Boom Point (1 or 2-part)

• Fixed Jib Point (1-part)

Single Part

Reeving

2-Part

Reeving

Location of Components at Boom Top Shown

Location of Components at Jib Tops is Similar

Figure 5-32. Block-Up Limit Components

11

M100767a

• Lower Boom Point (multiple part)

• Lower Boom Point (two lines over point)

• Fixed Jib Point (2-part)

See Load Block Reeving Diagrams for

Suggested Location of Weight with

Multiple Part Reeving

M100767b

11

8

Item Description

1 Lower Boom Point

2 Upper Boom Point

3 Block-Up Limit Switch

4 Chain (varying lengths)

5 Weight

6Lift Plate

7 Hook-and-Weight Ball

8 Weight

9Lift Block

10 Load Block

11 Chain, Shackle, and Pin

WARNING

Two-Blocking Hazard

Two-blocking is the condition in which the load block or

the hook-and-weight ball runs into the boom or jib

sheaves.

Two-blocking can result in failure of the sheaves and

wire rope, possibly causing the load to fall.

The operator shall determine the fastest line speed that

allows the block-up limit to function properly and

thereafter not exceed that line speed.

If the block or hook-and-weight ball approaches the

boom sheaves too fast, the block-up limit may not

prevent two-blocking.

Loading...

Loading...