Manitowoc Published 05-26-17, Control # 238-02 3-1

MLC165-1 SERVICE/MAINTENANCE MANUAL ELECTRICAL SYSTEM

SECTION 3

ELECTRICAL SYSTEM

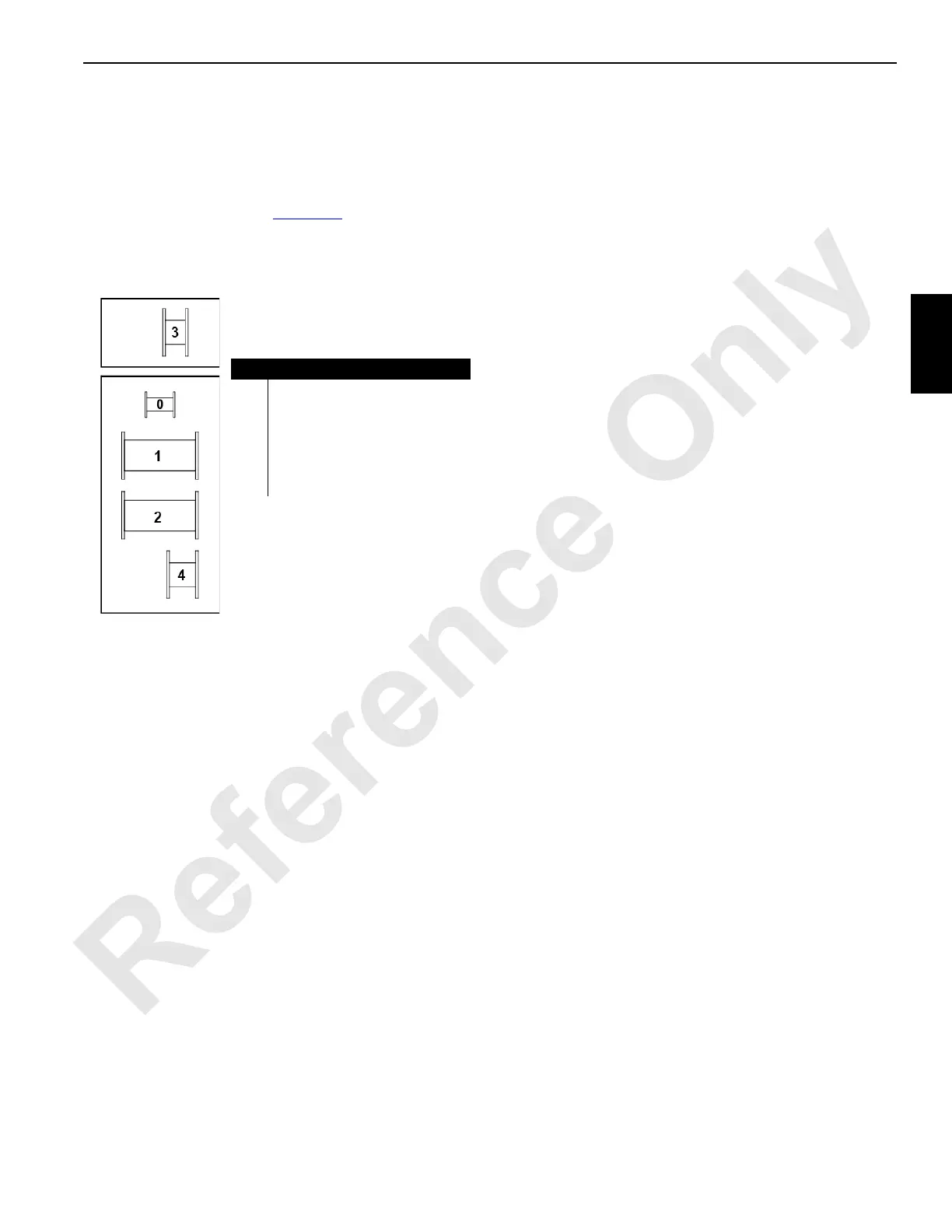

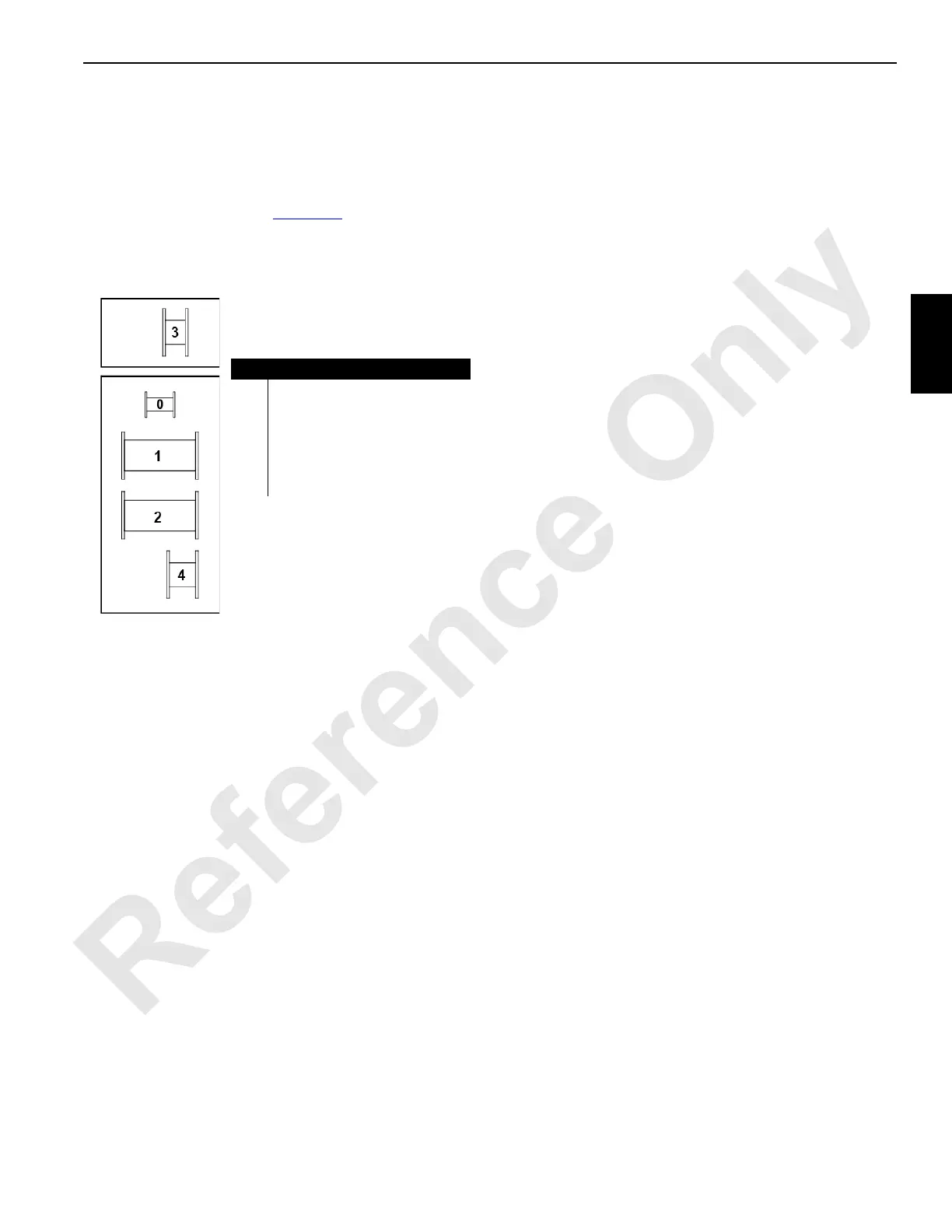

DRUM IDENTIFICATION

The drum numbers given in Figure 3-1 are used to identify

the drums in this section.

ELECTRICAL POWER SEQUENCE

Engine Bus Power

The batteries provide power through the battery disconnect

switch. When the switch is open, battery power is only

available to the grid heater. When the switch is closed,

battery power becomes available to the circuits powered by

the engine bus:

• Engine start and run switch

• Starter solenoid

• Engine Electronic Control Module (ECM)

• A/C circuit

• Horns

• Dome light

Cab Bus Power

With the battery switch closed and engine bus power

available, placing the ignition switch in the run position

closes the cab power relay in node 0, providing power to the

circuits on the cab bus:

• A/C and heater

• Wiper motors

• Panel lights

• Work lights

• Monitor

• Overhead console

• Engine Node 0

A DC to DC converter on the cab bus converts the 24Vdc

cab bus voltage to 12Vdc for use by boom power and the

radio.

CAN Bus Power

Engine Node 0 receives power from the cab bus and passes

that power to the controller area network bus (CAN Bus)

relay in node 0. The CAN Bus relay closes, providing power

to the remaining CAN Bus nodes, as well as the boom and

luffing jib remote input nodes (RIN).

CAN BUS CONTROL SYSTEM

CAN is a multi-master broadcast serial bus standard for

connecting nodes. Each node is able to send and receive

messages, but not simultaneously. A message consists

primarily of an ID, which represents the priority of the

message, and up to eight data bytes. It is transmitted serially

onto a two wire differential bus.

CAN uses priority based bus arbitration. If the bus is free,

any node may begin to transmit. If two or more nodes begin

sending messages at the same time, the message with the

higher priority ID sends its message, which is received by all

nodes.

A transceiver within each node translates voltage and

current levels between the microprocessor and the

differential bus. When receiving, it converts signal levels

from the bus to levels that the microprocessor uses. When

transmitting, it converts signals from microprocessor level to

the bus level.

Several types of node controllers are used with functionality

that matches the type of devices they are controlling and

communicating with.

Item Description

0 Rigging Winch

1 Front Load Drum (whip hoist)

2 Rear Load Drum (main hoist)

3 Auxiliary Load Drum or Luffing

Hoist (in boom butt)

4Boom Hoist

Front of Crane

Figure 3-1. Drum Identification

M101099

Loading...

Loading...