ACCESSORIES MLC165-1 SERVICE/MAINTENANCE MANUAL

10-6

Published 05-26-17, Control # 238-02

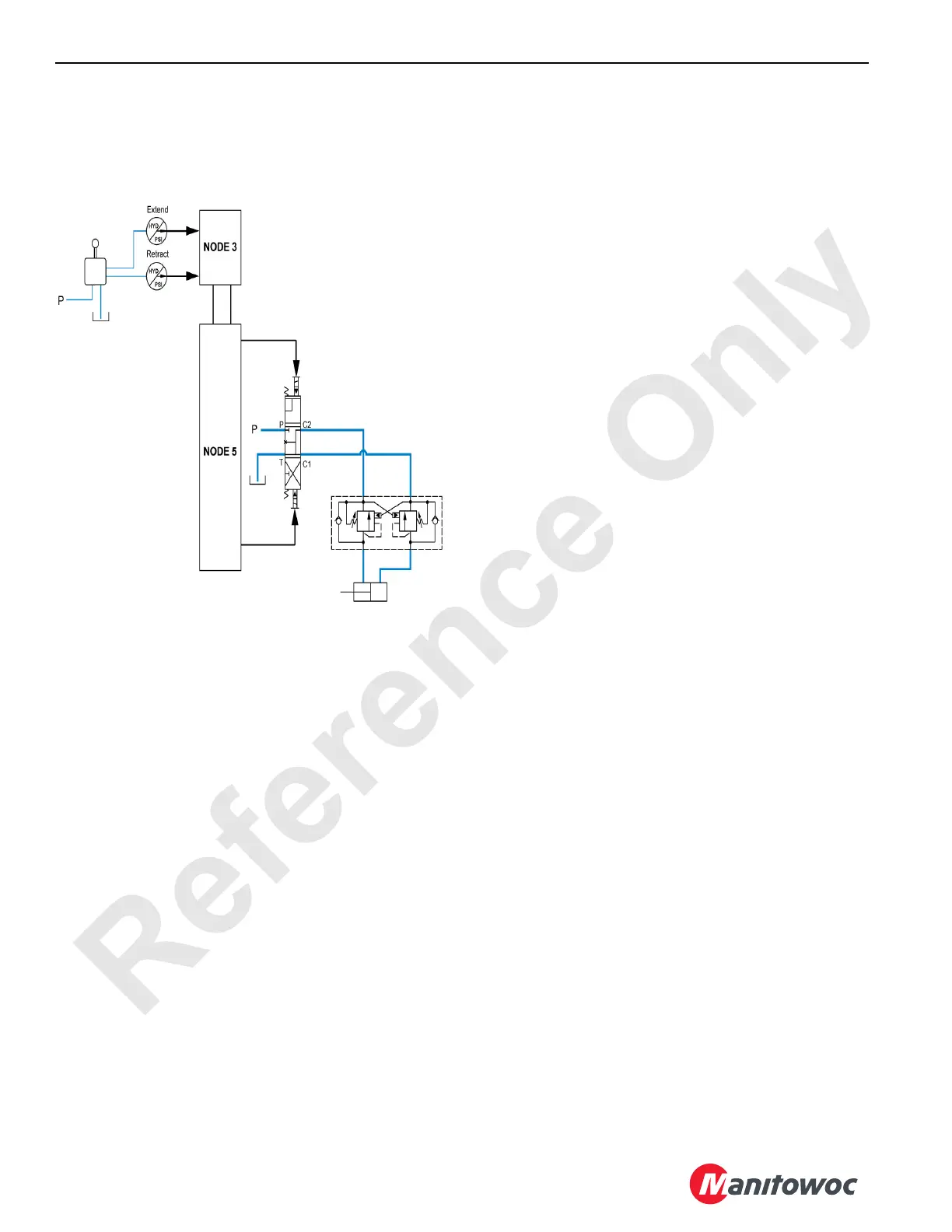

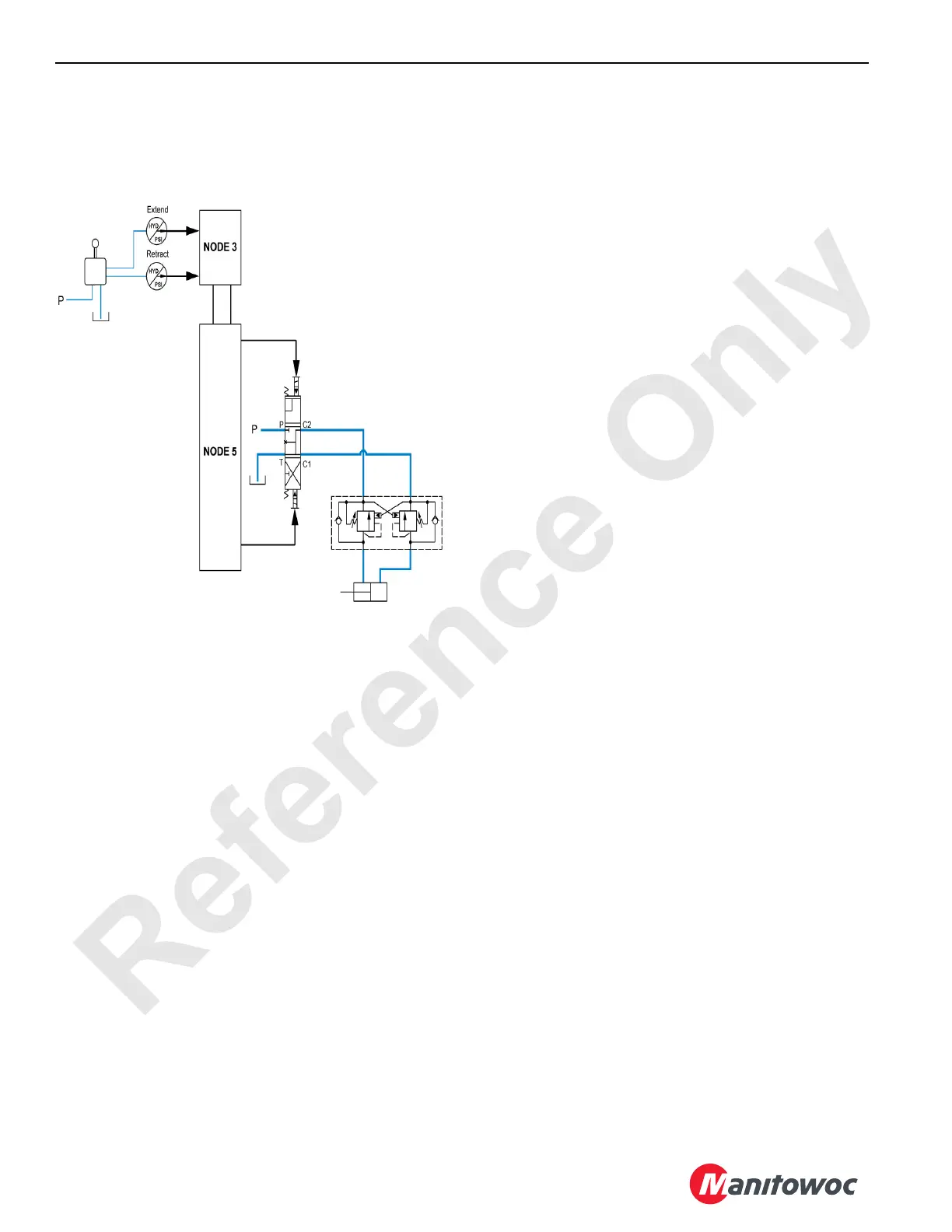

Assembly Cylinder (Optional)

Neutral

While drum 3/4 handle is in the neutral position, node 3

receives no out-of-neutral threshold pressure signal from the

drum 3/4 pilot pressure transducer. Node 5 drives no

solenoids in this state, so the valve spool is centered by the

return springs in the neutral position. The center valve

position is closed, so no fluid flows to the cylinder. The

holding valves are also in the closed position, so no fluid can

flow from the rod or barrel end of the cylinder if a load on the

cylinder is producing pressure.

Extend

When the drum 3/4 handle is pushed forward, node 3

receives an out-of-neutral threshold pressure signal from the

drum 3/4 pilot pressure transducer. Node 5 then sends a

24Vdc signal to the assembly cylinder extend solenoid,

energizing it.

The valve spool moves to the open position. Fluid flows from

the pressure port, through the valve, and on to the holding

valve. At the holding valve, fluid flows through the check

valve at the barrel end of the valve and into the barrel end of

the cylinder. At the same time, fluid opens the valve at the

rod end of the cylinder. As fluid fills the barrel end of the

cylinder, the rod extends and the movement forces fluid out

of the rod end, through the open holding valve, through the

open valve, and back to tank.

The accessory system pump pressure command is

proportional to the drum 3/4 handle position. This allows the

assembly cylinder pressure to vary refining the extend or

retract at a controlled speed.

Retract

When the drum 3/4 handle is pulled back, node 3 receives an

out-of-neutral threshold pressure signal from the drum 3/4

pilot pressure transducer. Node 5 then sends a 24Vdc signal

to assembly cylinder retract solenoid, energizing it.

The valve spool moves to the reversing position. Fluid flows

from the pressure port, through the valve, and on to the

holding valve. At the holding valve, fluid flows through the

check valve at the rod end of the valve and into the rod end

of the cylinder. At the same time, fluid opens the valve at the

barrel end of the cylinder. As fluid fills the rod end of the

cylinder, the rod retracts and the movement forces fluid out

of the barrel end, through the open holding valve, through

the open valve, and back to tank.

The accessory system pump pressure command is

proportional to the drum 3/4 handle position. This allows the

assembly cylinder pressure to vary refining the extend or

retract at a controlled speed.

M100838

Figure 10-7. Assembly Cylinder Control

Loading...

Loading...