Manitowoc Published 05-26-17, Control # 238-02 5-7

MLC165-1 SERVICE/MAINTENANCE MANUAL HOISTS

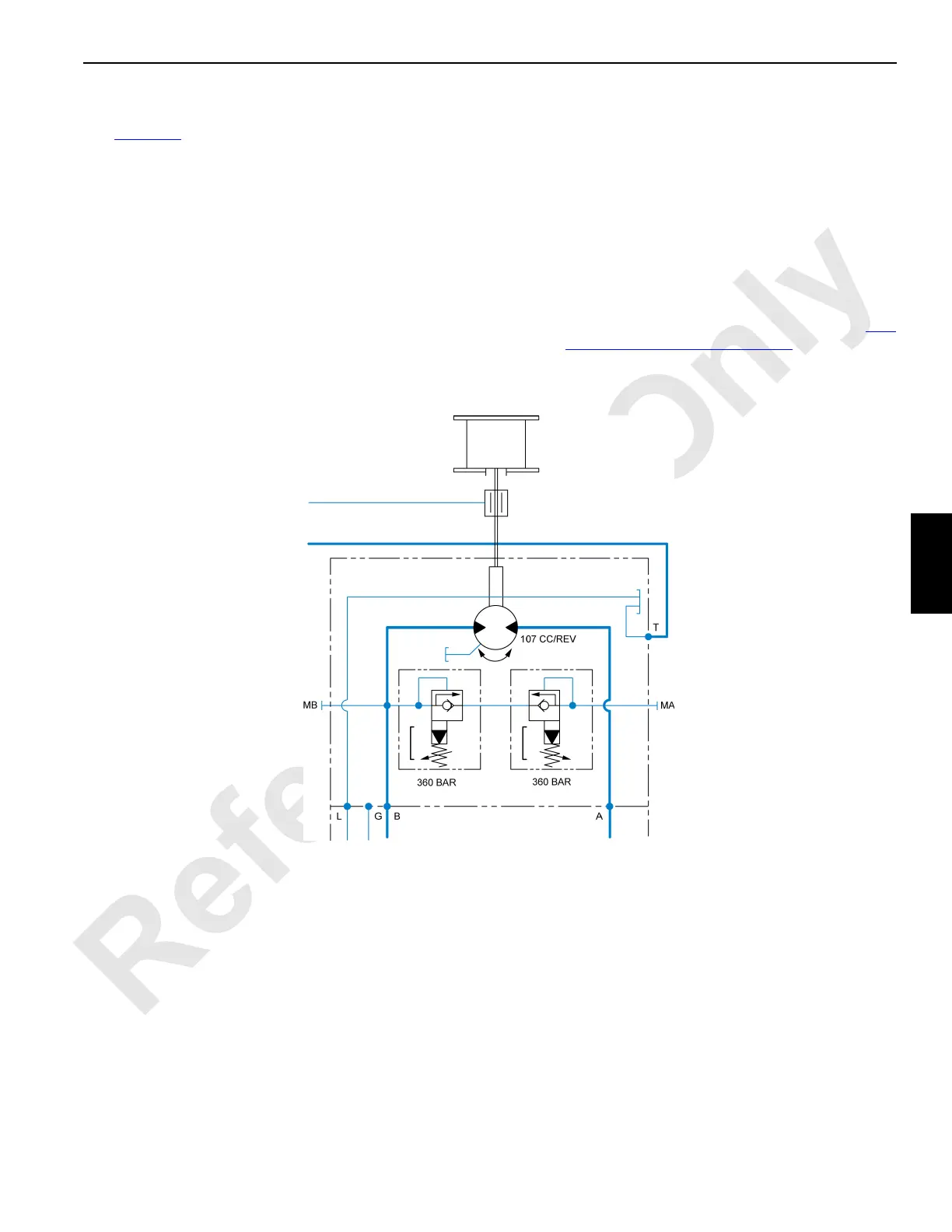

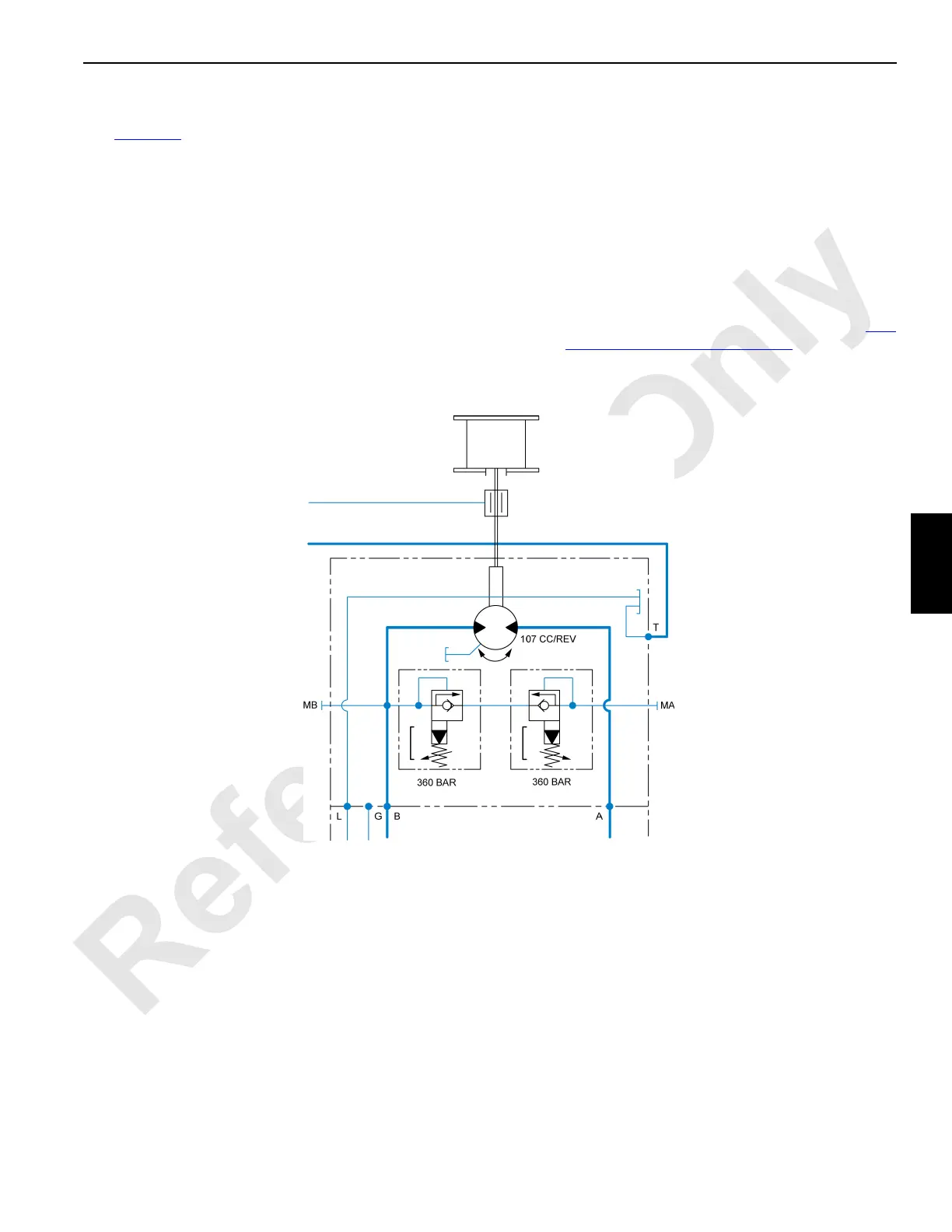

Drum 3 and Drum 4 Motor

See Figure 5-4.

The fixed axial piston motors for hoists 3 and 4 are identical.

Speed is governed by the position of the hoist control handle.

Internal leakage exits via a tank port. Cooling is

accomplished by working flow.

Pressure Relief

For motor protection, each motor has two pilot-operated

pressure-relief valves, one for hoisting and one for lowering.

Relief pressure is factory-set to (5,217 psi) 360 bar.

Test Meter Ports

Ports MA and MB are for connecting a pressure test meter to

the respective work flow circuit.

Speed Sensor

When a drum motor rotates, a hall-effect sensor mounted on

the motor sends an input voltage to the designated node

controller. The controller in turn sends corresponding voltage

pulses to the rotation indicator in the control handle.

NOTE If the drum is equipped with a free fall brake, the

motor-mounted speed sensor is not used. In its

place is an external encoder-type sensor. See Free

Fall System (Optional) on page 5-8.

Figure 5-4. Hoist Drum 3 and 4 Motor Diagram

Loading...

Loading...