POWER TRAIN MLC165-1 SERVICE/MAINTENANCE MANUAL

7-12

Published 05-26-17, Control # 238-02

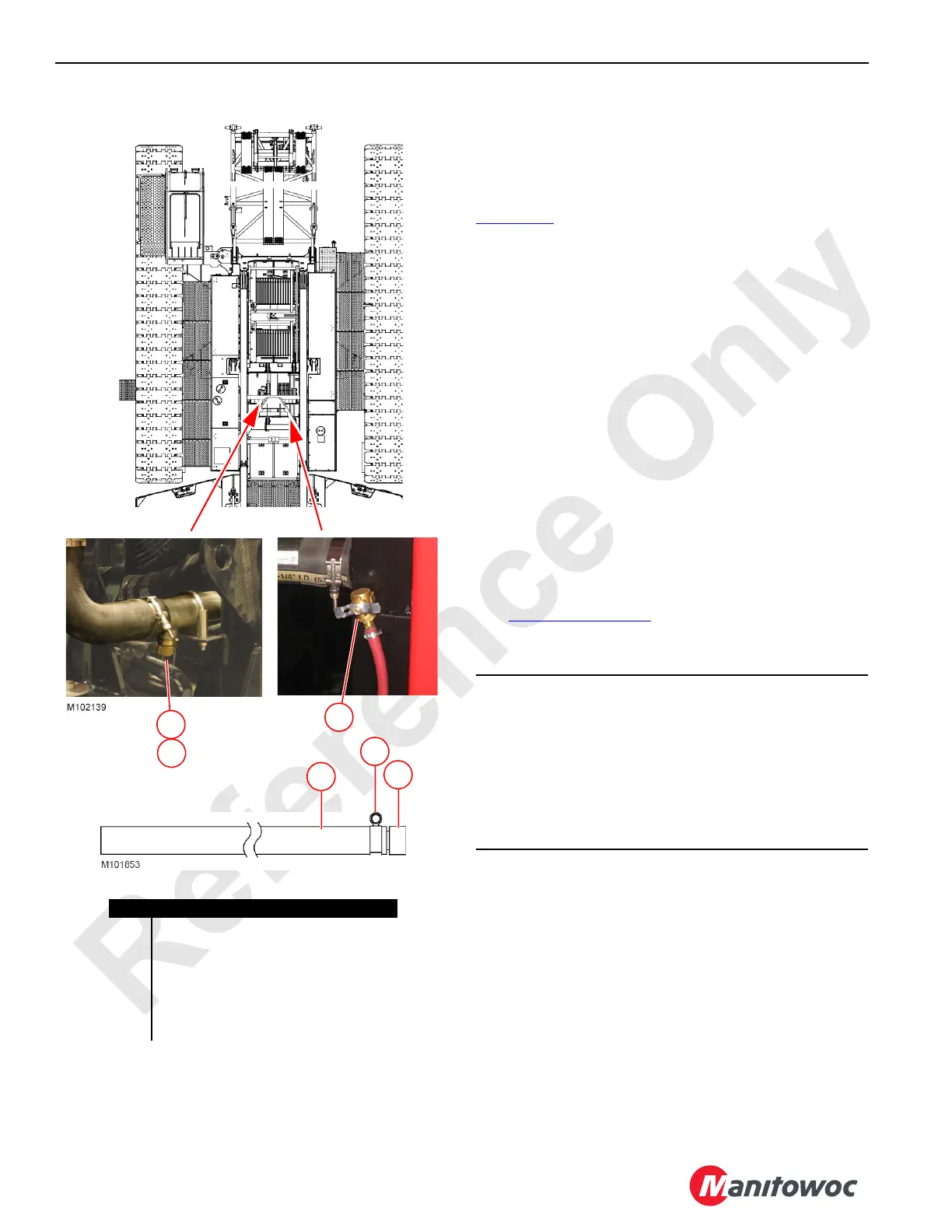

Draining and Filling Cooling System

Drain the cooling system every 1,000 hours of operation or

semi-annually (whichever occurs first).

The radiator is equipped with a quick-drain valve (2) which

requires use of the quick-drain drainer assembly shown in

Figure 7-10

. The quick-drain drainer assembly is stored in

the parts box supplied with the crane.

1. Insert the quick-drain hose (6) into a suitable container

which will hold 15 gal (57 L) of drained coolant.

2. Remove the cap (1) and attach the quick-drain drainer

(4) to the quick-drain valve (2).

3. The fluid will drain.

4. Remove the quick-drain drainer (4) from the quick-drain

valve (2) when the system is completely drained.

5. Install the cap (1).

6. Thoroughly clean the quick-drain hose and store the

assembly.

7. Check that the cab heater valves on the engine are

open.

8. In the cab, place the heat control to maximum.

NOTE It is not necessary to turn on the heater fan.

9. Open the access cover and remove the radiator fill cap

(Figure 7-9, page 7-11

).

10. Add a coolant additive (SCA) to the radiator.

11. Add a 50-50 mix of water and ethylene glycol to the

radiator.

NOTE The maximum fill rate is 3 GPM (11.4 liters/min).

NOTE The capacity of the cooling system is

approximately 13 gal (49 L).

Figure 7-10. Radiator Drain Locations

Item Description

1Cap

2 Quick-Drain Valve (drains entire system)

3 Drain Valve (drains only radiator)

4 Quick-Drain Drainer

5 Hose Clamp

6 Hose: 3/4 in (19 mm) Inside Diameter by

10 ft (3,0 m) Long

M100517

1

2

3

4

6

5

CAUTION

Maintain Coolant Additive

A proper concentration of a Supplemental Coolant

Additive (SCA) must be maintained to prevent engine

damage.

Check the SCA concentration according to the schedule

in the engine manufacturer’s manual and per the

manufacturer’s warnings, cautions and instructions.

Loading...

Loading...