UNDER CARRIAGE MLC165-1 SERVICE/MAINTENANCE MANUAL

8-8

Published 05-26-17, Control # 238-02

CRAWLER HAND PUMP AND JACKING

CYLINDER

Assembly

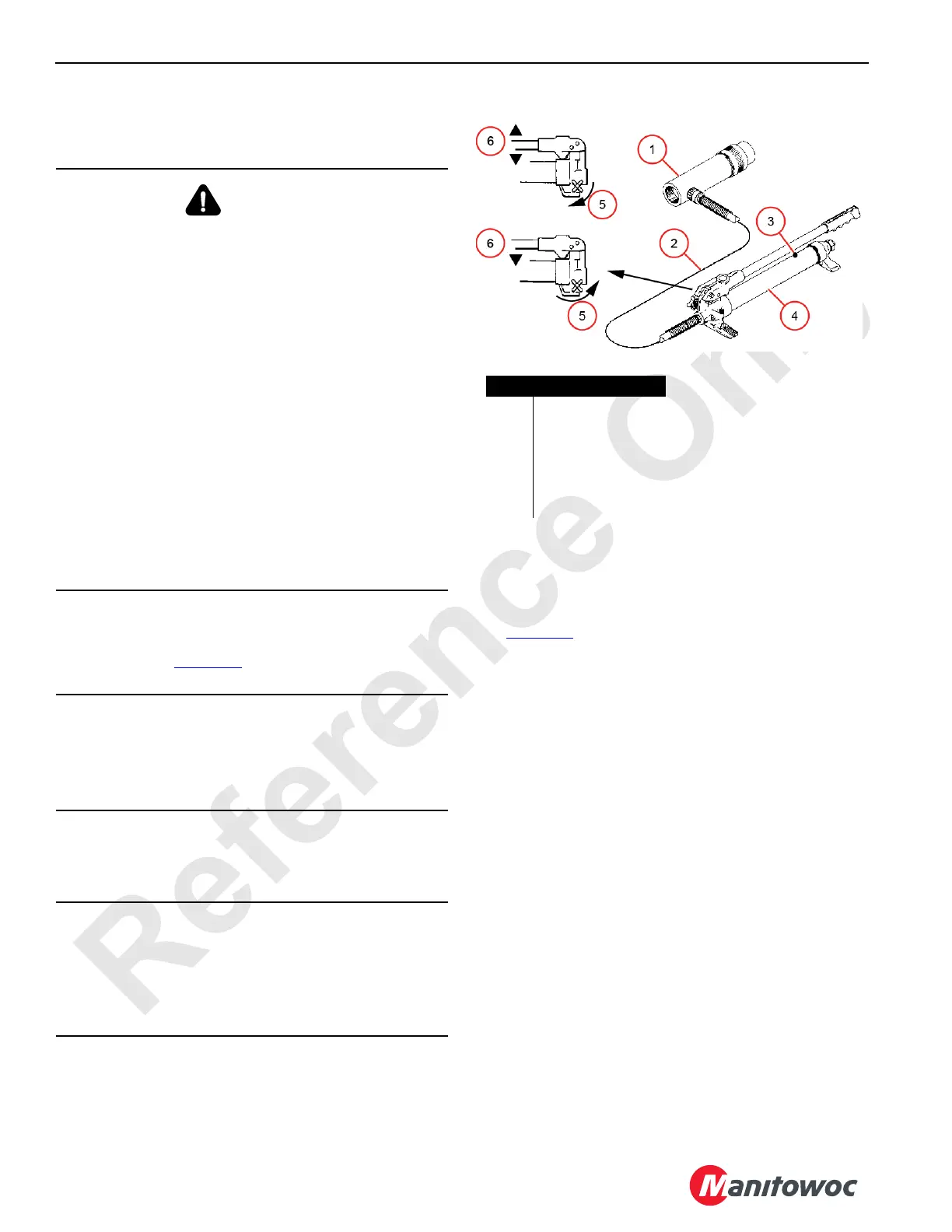

1. Connect the hose from the pump outlet port to the

cylinder inlet (Figure 8-5

).

2. Apply 1-1/2 wraps of a high-grade thread sealant (Teflon

tape) to the fittings.

Maintenance

See Figure 8-5 for the following procedure.

1. Keep the unit clean and stored in a safe place where it

cannot be damaged.

2. Assure correct pump oil level. To check the level:

a. Turn the pump valve (5) counter-clockwise, push

the jacking handle (6) all the way down, and fully

retract the jacking cylinder (1) rod to return all oil to

the pump. The cylinder must be fully retracted or

the system will contain too much oil after filling.

b. Place the pump (4) horizontally on a flat surface.

c. Using a screw driver, remove the vent fill cap (3).

d. Add hydraulic oil to the pump until the reservoir is

two-thirds full. Do not overfill.

e. Reinstall the vent fill cap.

f. Test pump operation and remove air from system, if

required. Recheck oil level after removing the air.

WARNING

Hand Pump Explosion

The hand pump and cylinder is provided for crawler

adjustment only, any other use is neither intended nor

approved.

Wear safety glasses and other personal protective gear

when operating the hand pump.

Do not set the pump relief valve higher than 10,000 psi

(700 bar). Higher pressure can cause components to

explode.

The pump is not vented. It can explode if subjected to high

pressure. Do not attempt to return more oil to the pump

than it is capable of holding. Do not overfill the pump.

In some cases, the pump handle can “kickback.” Always

keep your body to side of pump, away from line of handle

force.

Do not add extensions to handle. Extensions can cause

unstable operation.

CAUTION

Hand Pump Damage

Do not apply sealant to the first complete thread to ensure

the sealant does not shed into the hydraulic system and

cause malfunctioning or damage.

CAUTION

Leaks and Fitting Damage

Do not overtighten the connections, connections only

need to be snug and leak free. Overtightening can cause

premature thread failure and may cause fittings or

castings to split at lower than their rated pressures.

M100737

Figure 8-5. Crawler Hand Pump

Item Description

1 Jacking Cylinder

2Hose

3Vent Fill Cap

4Pump

5Valve

6 Jacking Handle

Loading...

Loading...