POWER TRAIN MLC165-1 SERVICE/MAINTENANCE MANUAL

7-4

Published 05-26-17, Control # 238-02

Storage

When the crane is left idle for prolonged periods, the

batteries should be periodically charged.

When storing a battery, make sure it is least 75% charged to

prevent sulfation and the possibility of freezing.

Follow your battery dealer’s recommendations.

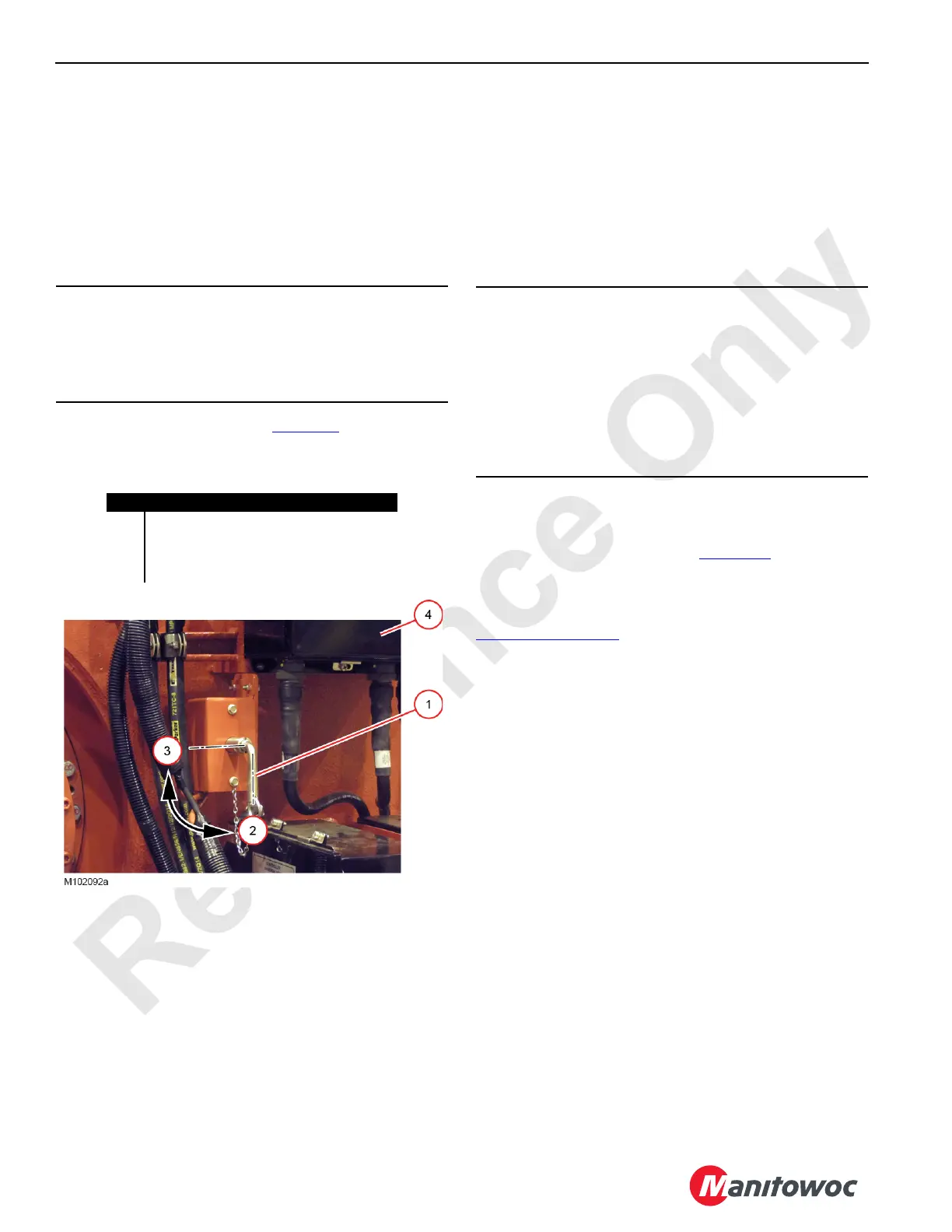

BATTERY DISCONNECT SWITCH

The battery disconnect switch (1, Figure 7-3) is located in the

right-side enclosure next to the engine Node 0.

The switch disconnects the engine controller (Node 0) from

the positive side of the battery. Since the rest of the crane’s

control system is powered through Node 0, opening the

disconnect switch effectively removes power from the entire

control system.

To operate the battery disconnect switch:

• Turn handle COUNTERCLOCKWISE to DISCONNECT

the control system to the battery (handle vertical and

removable).

• Turn handle CLOCKWISE to CONNECT the control

system from the battery (handle horizontal).

The following are reasons for using the disconnect switch:

• When servicing crane’s electrical control system

• To help prevent the batteries from discharging when the

crane is stored for extended periods of time

• To prevent the crane from being started by unauthorized

personnel

BATTERY CHARGER

When a customer supplied 240VAC power source is

connected to the receptacle (4, Figure 7-4

), the optional

battery charger will supply up to 10 amps of 24V power to the

crane batteries.

If an alternative method of charging is desired, see

Charging

on page 7-3.

If the crane is not to be used for more than a few days,

the charger should be plugged in to a 240VAC source.

There is a 20A fuse on the DC output. For charger

troubleshooting and maintenance information, refer to the

manufacturer’s service manual.

ENGINE CONTROLS

See the engine start procedure in Section 3 of the MLC165-1

Operator Manual for engine startup. See the Cummins

engine manual for detailed engine instructions.

The engine is started and stopped with the engine key

switch.

The speed of the crane motors and actuating cylinders

depends on engine speed and equipment control handle

movement. Engine speed is controlled with the hand throttle

or foot throttle and is monitored with a speed sensor. Node 1

controller and engine Node 0 controller control and process

engine information, which is shown on the main display.

The emergency stop push button stops the engine in an

emergency. All brakes will apply and any functions will stop

abruptly.

CAUTION

Avoid Engine Damage

To avoid possible engine fault codes and undesirable

operation, make sure the ignition switch has been off five

minutes before disconnecting the batteries.

Figure 7-3. Battery Disconnect Switch

Item Description

1 Battery Disconnect Switch

2 Disconnected (handle can be removed)

3 Connected

4 Engine Node 0

CAUTION

Avoid Control System Damage

Before Welding:

• Disconnect the battery cables at the batteries.

• Disconnect the cabling from any control node

enclosures that are in the vicinity of the welding.

Do not rely on the disconnect switch to protect the crane’s

electronic systems when welding.

Loading...

Loading...