OPERATOR'S MANUAL

ENGLISH

Cod. EKE0002OM

77

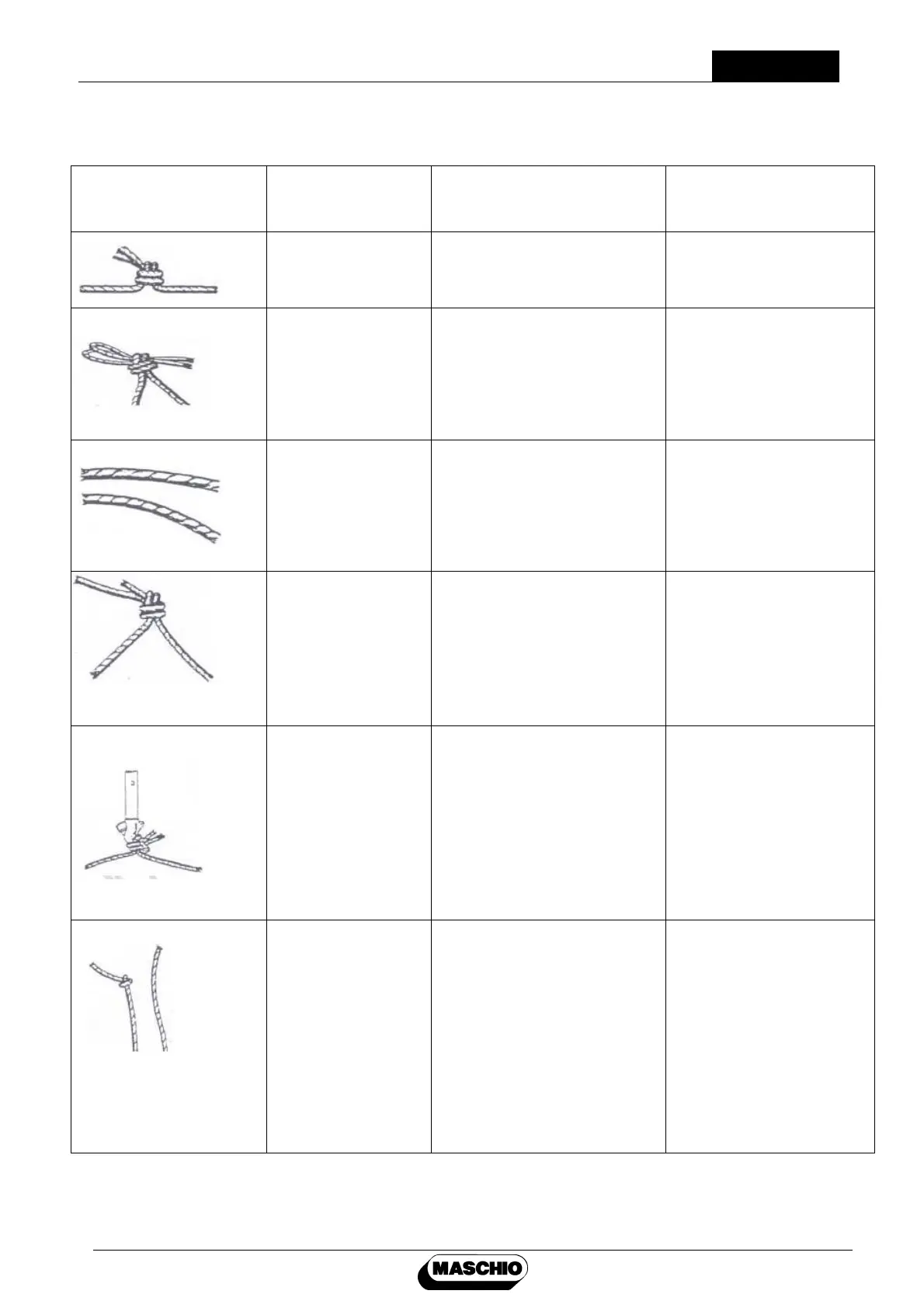

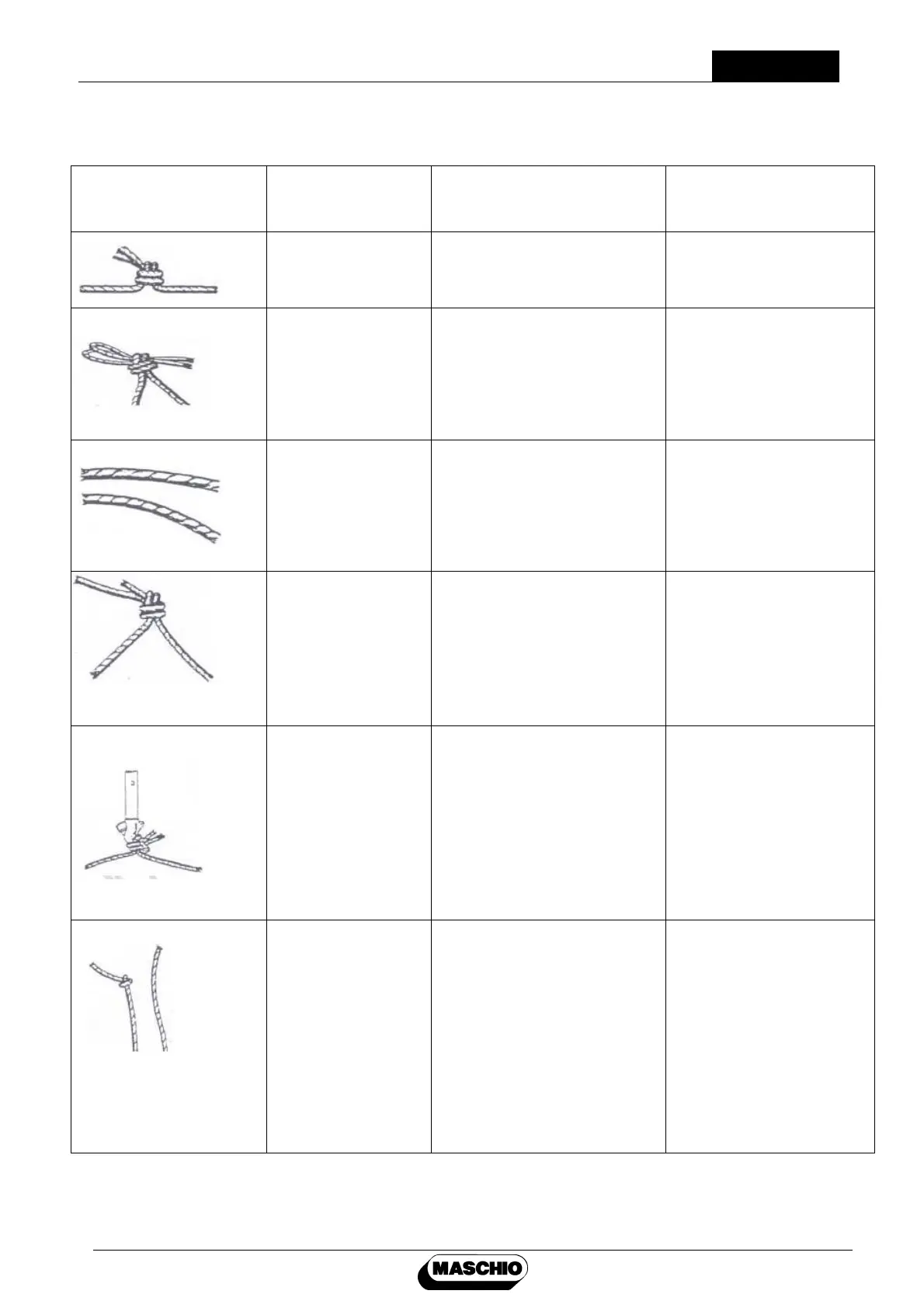

Table 5.13.1: Knotter Set Troubleshooting and Solutions

FORM OF KNOT PROBLEMS CAUSES SOLUTIONS

Standard knot.

Clean-cut tips of

twine.

knotting. Curling

sticks hook latch and

twine breaks.

Adjustment of hook spring is

loose

Please screw the nut

increasing spring tension

by quarter round.

Knotter set does not

knot.

1- Spring of holder disc is

loose during knotting, twine

deviates early.

2- Twine puller is unable to

bring twine close to the hook.

1- Increase twine retainer

spring compression.

2- Adjust twine puller.

1- Tips of knot are

not equal length.

2- Both tips cut short

1-

Blade might be blunted.

2- The pressure of spring on

twine holder disc is not

enough

3- Calibre between knotting

and chassis may break down.

1- Grind the blade.

2- Adjust twine holder

3- Check the measure of

70 ml knotting to chassis

Knots get stuck on

the hook.

1- Over spacing between

stripper rod and hook.

2- Stem may be among twine.

3- Twine may be stuck at

some point

4- Measures between knot

and chassis may be broken.

5- Bales produced too tight.

1- Stripper rod must do

stripping.

2- Clean jammed stem

between twine and hook.

3- Provide twine at desired

tightness from twine box to

knotting.

1- Knot occurs on

one tip of twine.

2- Hook does not

knot two twines

together.

1- The adjustment of spacing

between twine puller linings

and needle is failed.

2-

Spring of twine holder might

be loose

3- Needle is at back descent,

twine does not lean to needle

1- The intermediate

distance of twine puller

linings and needle inner

surface should be 3 mm

utmost.

2- Increase spring tension

for twine holder not to

release twine.

3- Increase tightness of

twine on twine track.

Loading...

Loading...