“4069RT” Service and Parts ManualMarch 2014

Page 3-16

DIESEL ENGINE MAINTENANCE

6. Hold the High Speed Stop Screw while tightening the jam nut to prevent change in

adjustment.

T

HROTTLE

S

OLENOID

A

DJUSTMENT

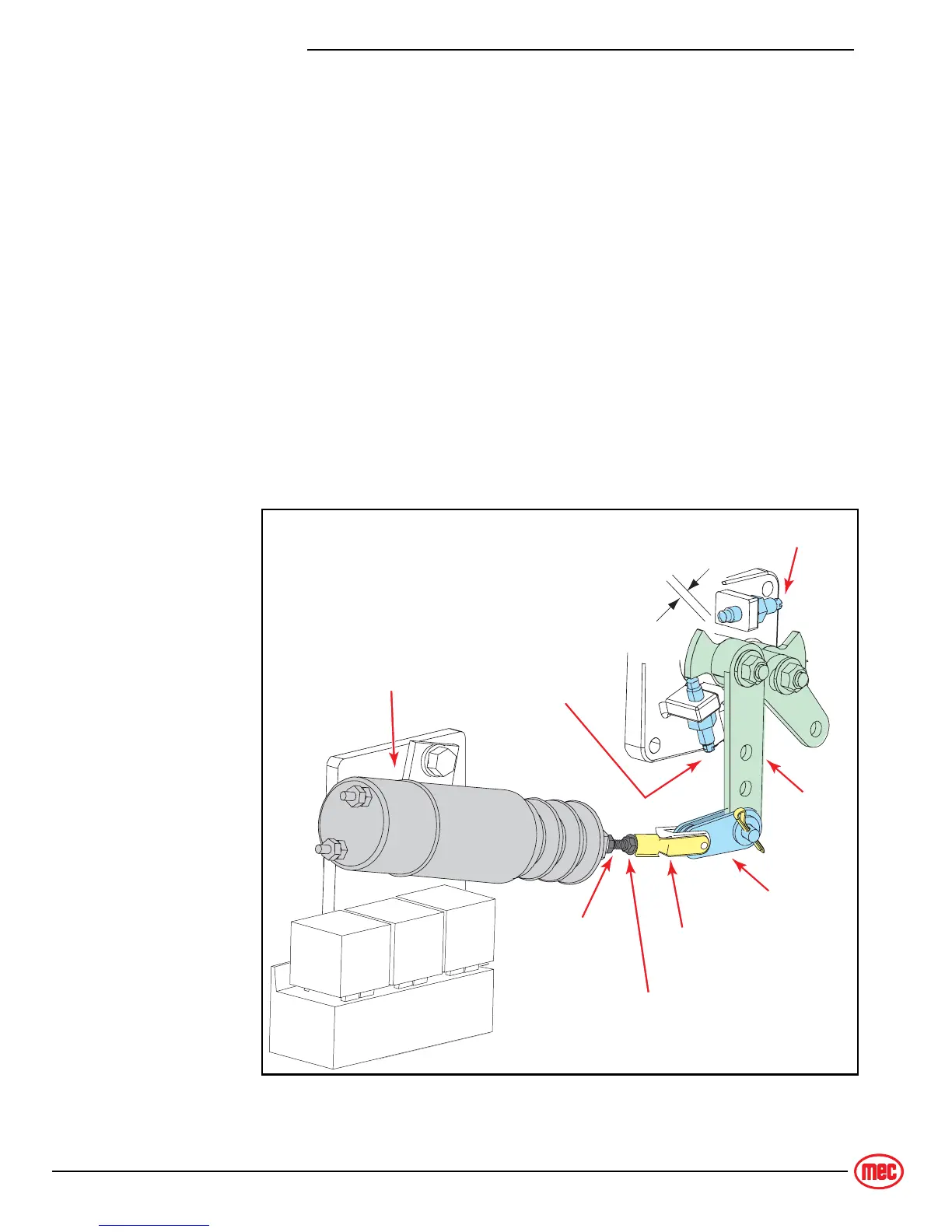

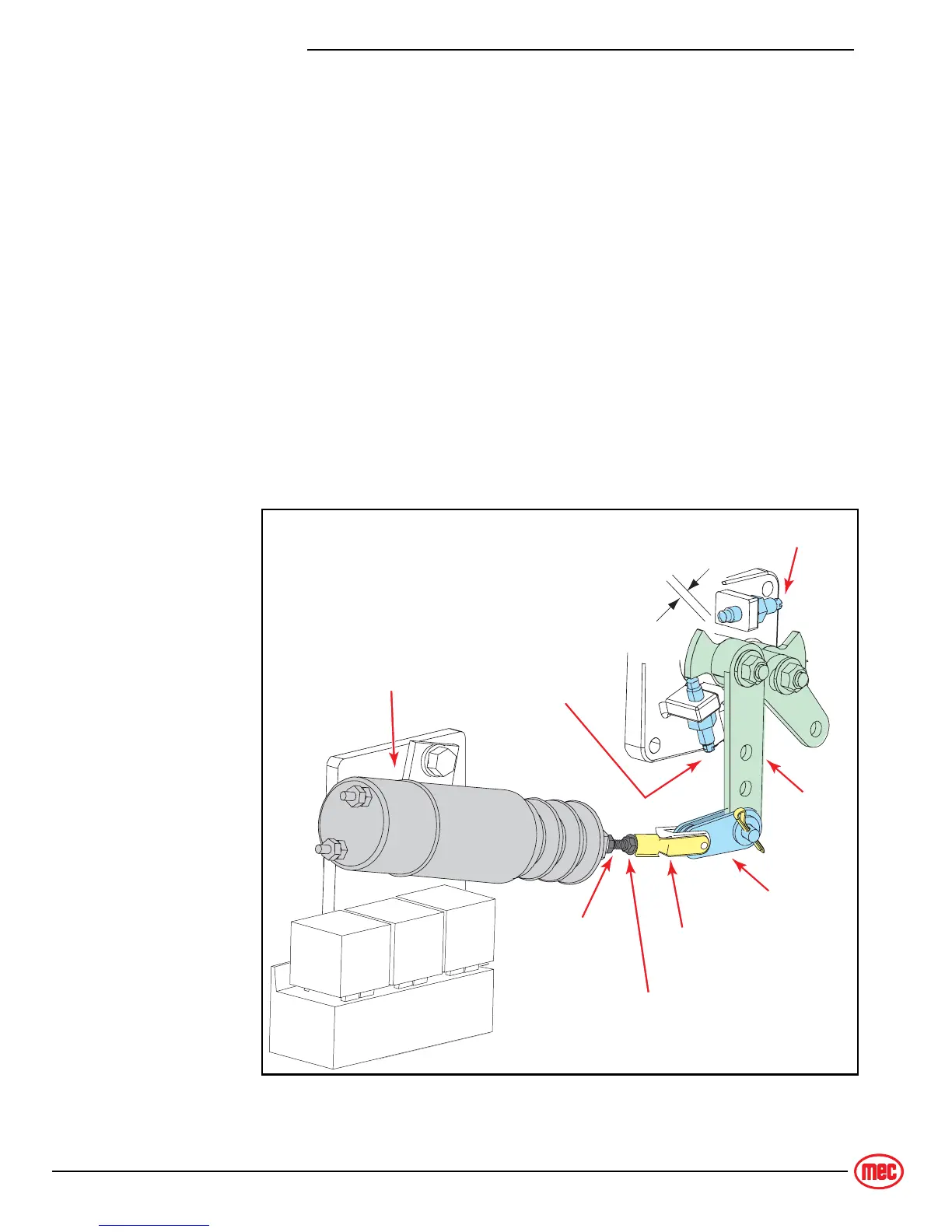

IMPORTANT: – This final adjustment must be made after all other throttle speed adjust-

ments. The solenoid must be free to retract fully in order to turn OFF the High Amperage

Pull Circuit. Improper adjustment will result in solenoid failure and may damage the electri-

cal system.

1. With the engine OFF, manually retract the solenoid by grasping the piston, just ahead

of the boot, and pull to the fully retracted position.

NOTE: The solenoid must retract and extend smoothly. If movement is impaired it may be necessary to reposition the

solenoid to improvement alignment.

2. With the solenoid piston fully retracted measure the distance between the High

Speed Stop Screw and the Throttle linkage using a .020 feeler gauge.

3. Adjust clearance at the Throttle Solenoid linkage only.

Do not adjust the High Speed Stop Screw.

• Disconnect the linkage at the clevis and turn the clevis to lengthen or shorten as necessary.

• Reconnect the clevis and measure again. Repeat until the measurement is correct.

Figure 3-11: Diesel Engine Throttle Adjustments

ART_4002

High Speed

Stop Screw

Idle Stop

Screw

.020

Throttle

Solenoid

Throttle

Solenoid

Piston

(Threaded Rod)

Throttle

Solenoid

Adjustment

Throttle

Lever

Throttle Link

Clevis

Loading...

Loading...