“4069RT” Service and Parts ManualMarch 2014

Page 3-10

STEER CYLINDERS

S

TEER

C

YLINDERS

NOTE: Refer to Section 1 for seal replacement instructions.

Refer to Parts Section D and E for detailed parts list and illustration.

There are two double-acting steer cylinders on this machine. During operation,

cylinder(s) should not leak, but a slight damping at the rod seal is acceptable. The pins

and rod-end joints should be checked for wear.

• Clean all fittings before disconnecting hoses.

• Tag hoses for proper reassembly.

• Plug all openings to prevent contamination.

Refer to “Lift and Support The Machine” in the Introduction section for instructions and

safety precautions.

Removal

1. Raise and support the machine.

2. Disconnect hydraulic hoses. Immediately cap and plug all openings to prevent con-

tamination.

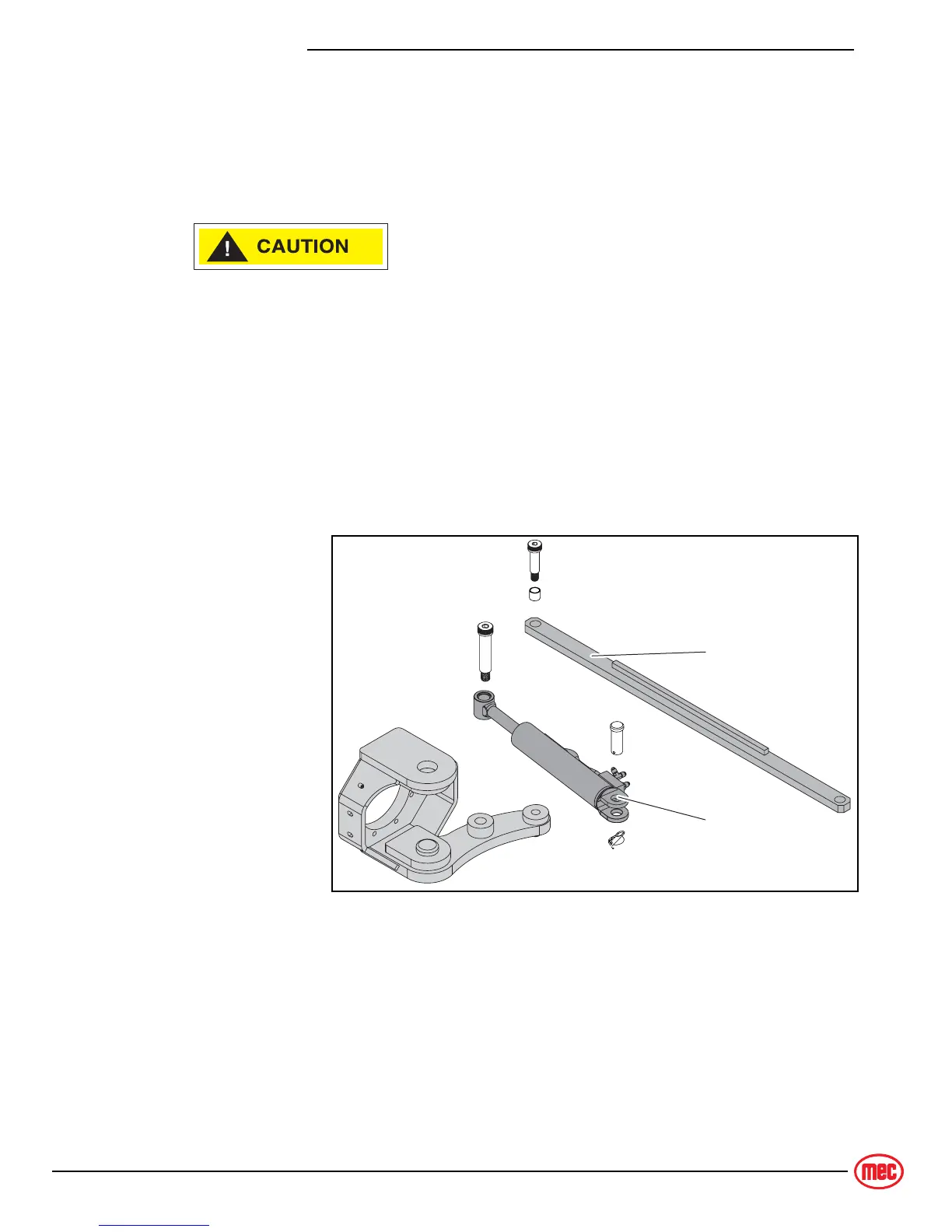

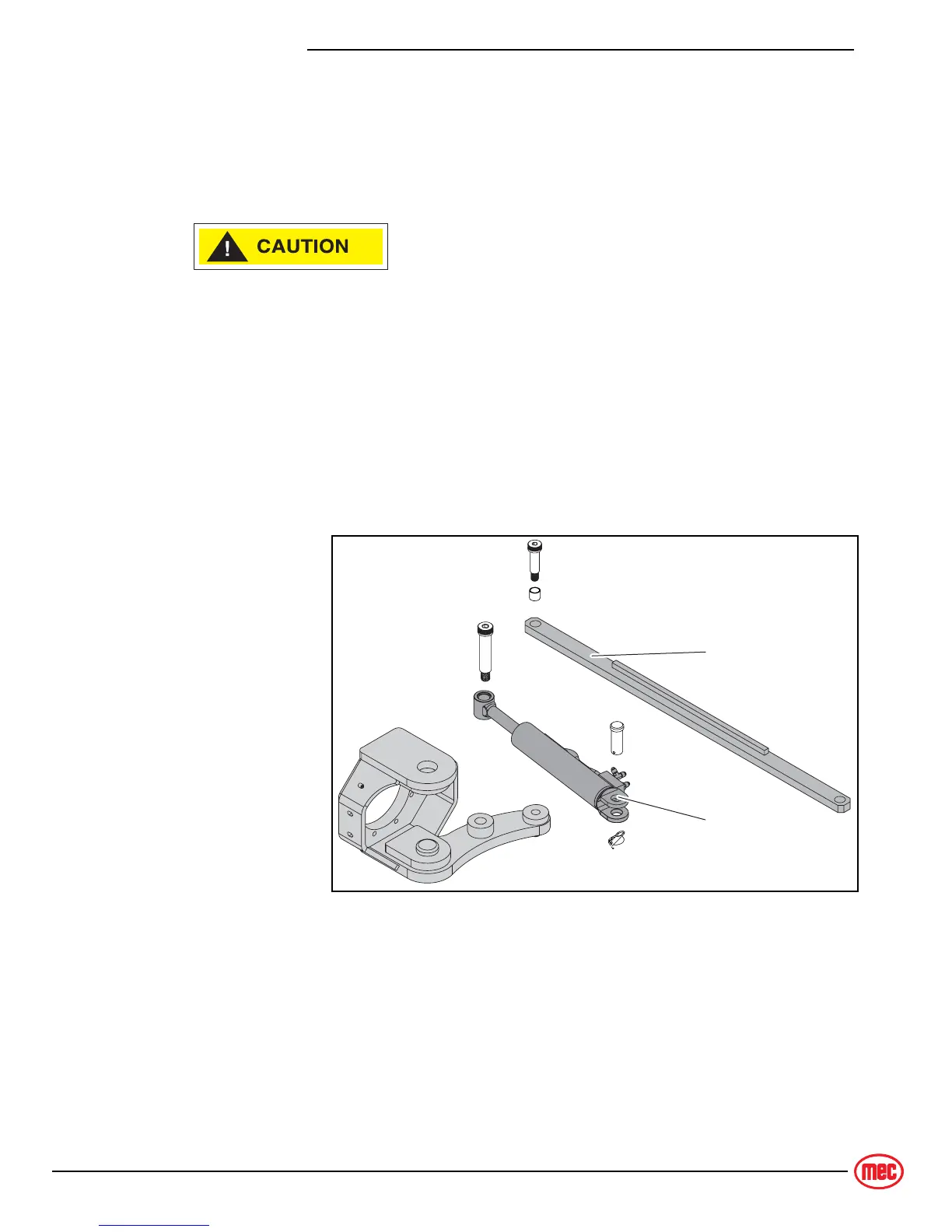

Figure 3-5: Steer Cylinder

3. Remove the tie rod.

4. Remove the shoul-

der bolt that

secures the rod

end of the cylinder

to the steering

yoke. Swing the

steering yoke out of

the way.

5. Remove the locking

cotter pin from the

clevis pin that

secures the barrel

end of the cylinder

to the chassis.

6. Support the cylin-

der, then remove the pin. Remove the cylinder.

Installation

Installation is reverse of removal.

• Use Loctite

242 or equivalent on mounting bolts.

• Torque all bolts to specifications listed in the Introduction Section of this manual.

• To purge air from cylinder, cycle the steering system fully left and right 4-5 times.

ART_4496

Tie Rod

Steer Cylinder

Loading...

Loading...