Chapter 7 Maintenance

160

7.3 Maintenance Methods

Ink Maintenance

If ink constituents are sedimented, the ink density may become uneven. We recommend shaking the ink

every three days to ensure consistent printing.

l

Shake the ink.

1

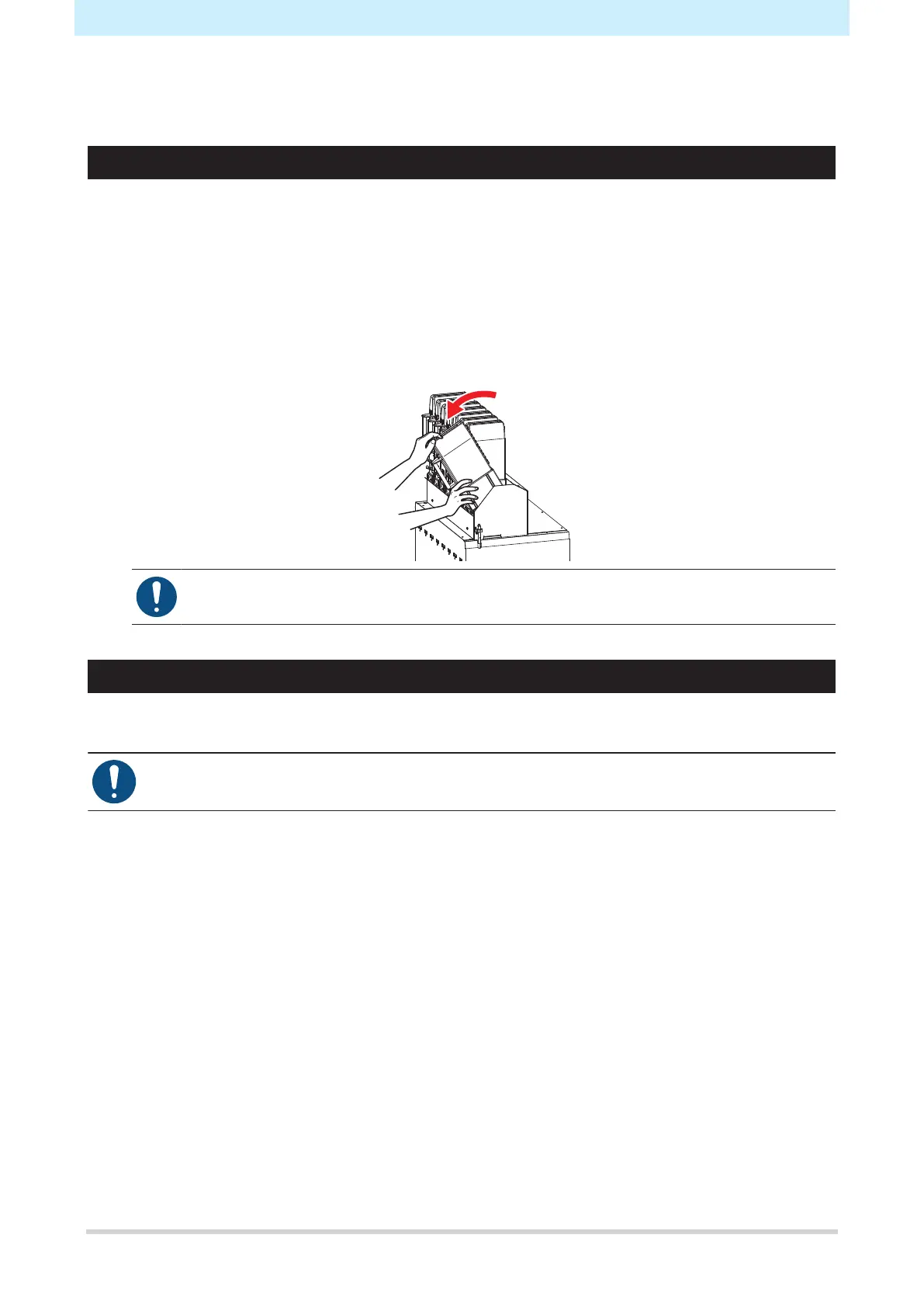

Shake the Ink eco-case slowly at least 10 times.

• Shake the Ink eco-case attached to the ink supply unit back and forth by holding its top and tilting

it to the front.

• Be sure to shake the ink eco-case back and forth by holding its top. The ink eco-case may

become detached if pulled upward.

Cap Rubber Cleaning

The cap prevents the print head nozzle surface from drying out. Continuing to use a dirty cap may affect ink

take-up and lead to print defects (e.g., nozzle clogging, deflection).

• Be careful to avoid leaving fragments from the cleaning stick behind when cleaning. These

fragments will increase the risk of printing defects (e.g., nozzle clogging or deflection).

1

On the LOCAL mode screen, select [MENU] > [Maintenance], then press the [ENTER] key.

• The Maintenance menu is displayed.

2

Select [Station Maint.] > [Carriage Out] > [Move To Platen Right End], then press the [ENTER]

key.

• The carriage moves over the platen.

3

Open the maintenance cover on the right side.

Loading...

Loading...