Chapter 1 Machine Setup 1-

11

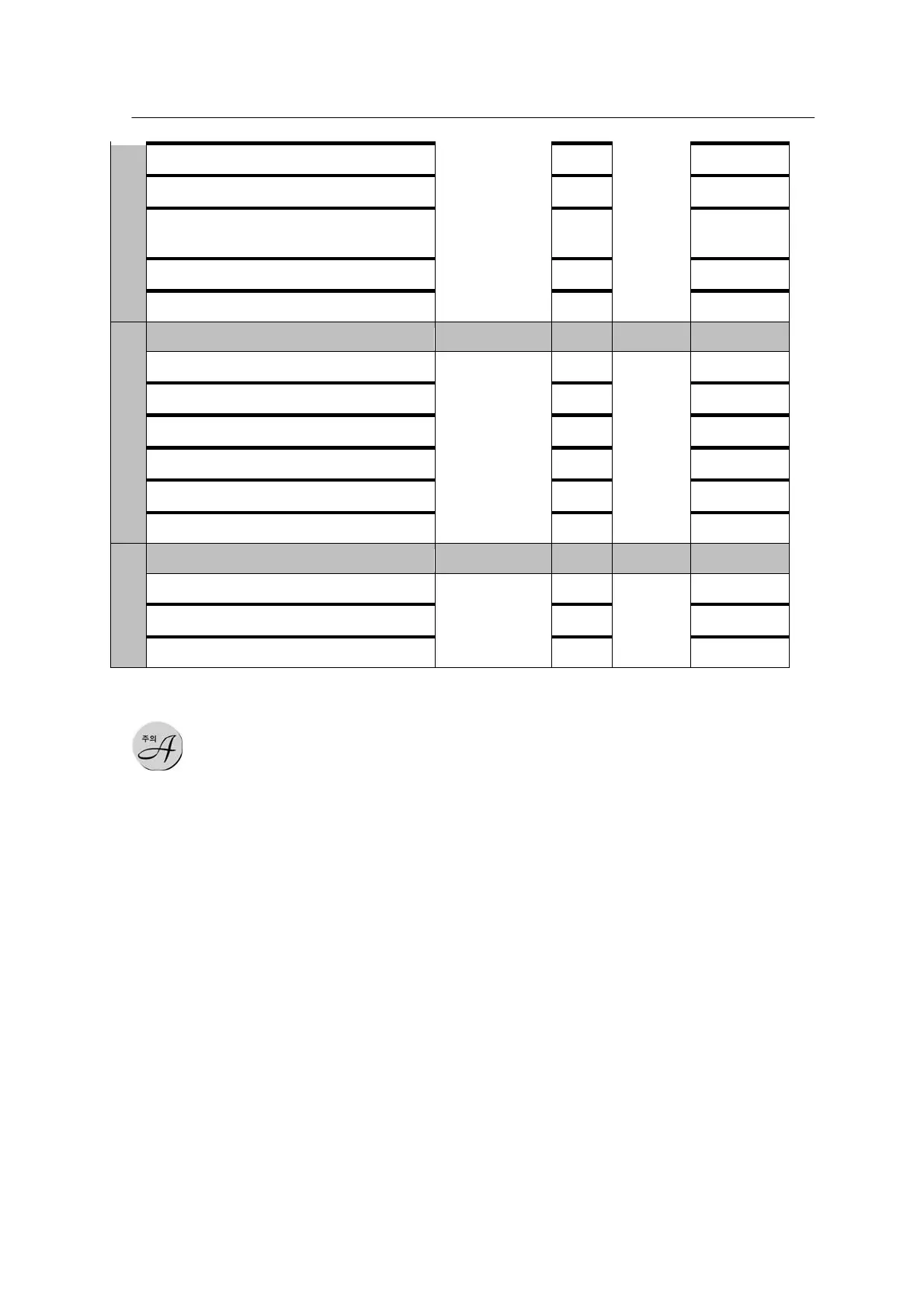

11. Tray support replacement

12. Grease feeding to rack & pinion

driving unit

13. LM guide grease feeding

3. Feeder clamp sensor block fixation

4. TF connection to the frame base

5. Hole processing unit chamfering

1. Power and air connection

2. Assembly status (fixation, balance)

3. Motor and belt fixation

CIS 4 : Assembly Check

When moving the

gantry, grip the vision

cover (black) of the

head with hand to

make it not move

Packing

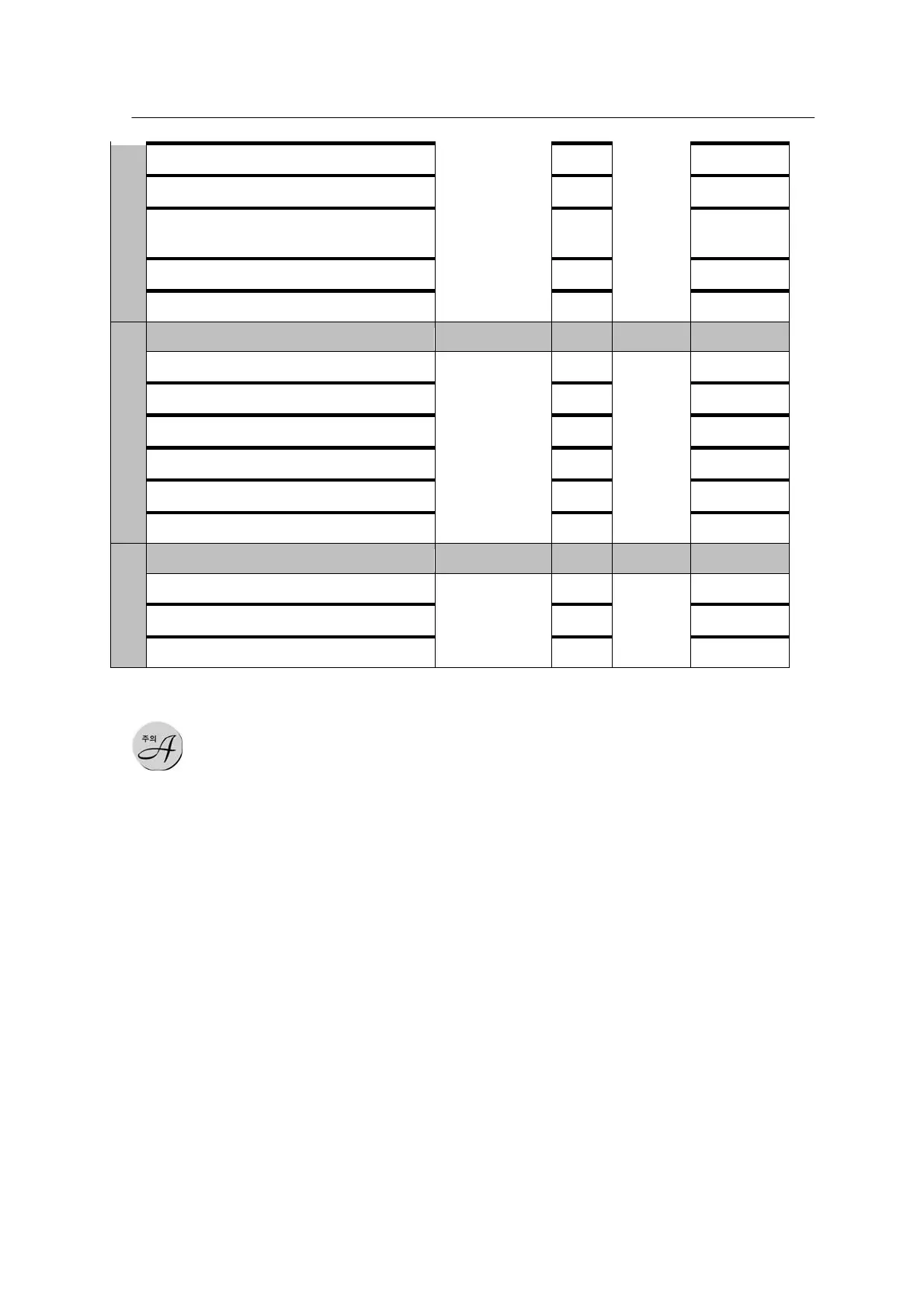

list check

Check

that the

equipment

was

packed

according

to the

packing list

prepared

upon

delivery and check the optional parts, if any. Ensure that

there are no defects in the packing box of the equipment.

Ensure that the machine is not affected by damage to the

packing box.

Machine leveling check

Machine level

Using a level meter, adjust the level offset between the front and

rear feeder bases at the top/bottom and the left/right to less than

30 ㎛.

Pre/Post process level

Check that the conveyor is level using a height gage.

Foot size Record the foot size.

Foot height

Adjust the machine level and record the foot height.

Loading...

Loading...