Chapter 4 Regular Chec4k- 4-45

4.It the tension is not within the normal tension range (60±10N), loosen the idle pulley with a

wrench and adjust to a moderate tension, while moving it up and down.

5.Firmly fix the idle pulley.

6.Assemble the vision cover on the front.

Half-yearly Check (Every 3000 Hours)

Checking surface treatment of exposed steel parts

Module: X-Y Gantry

The corrosion-prone parts of the machine can be checked as below.

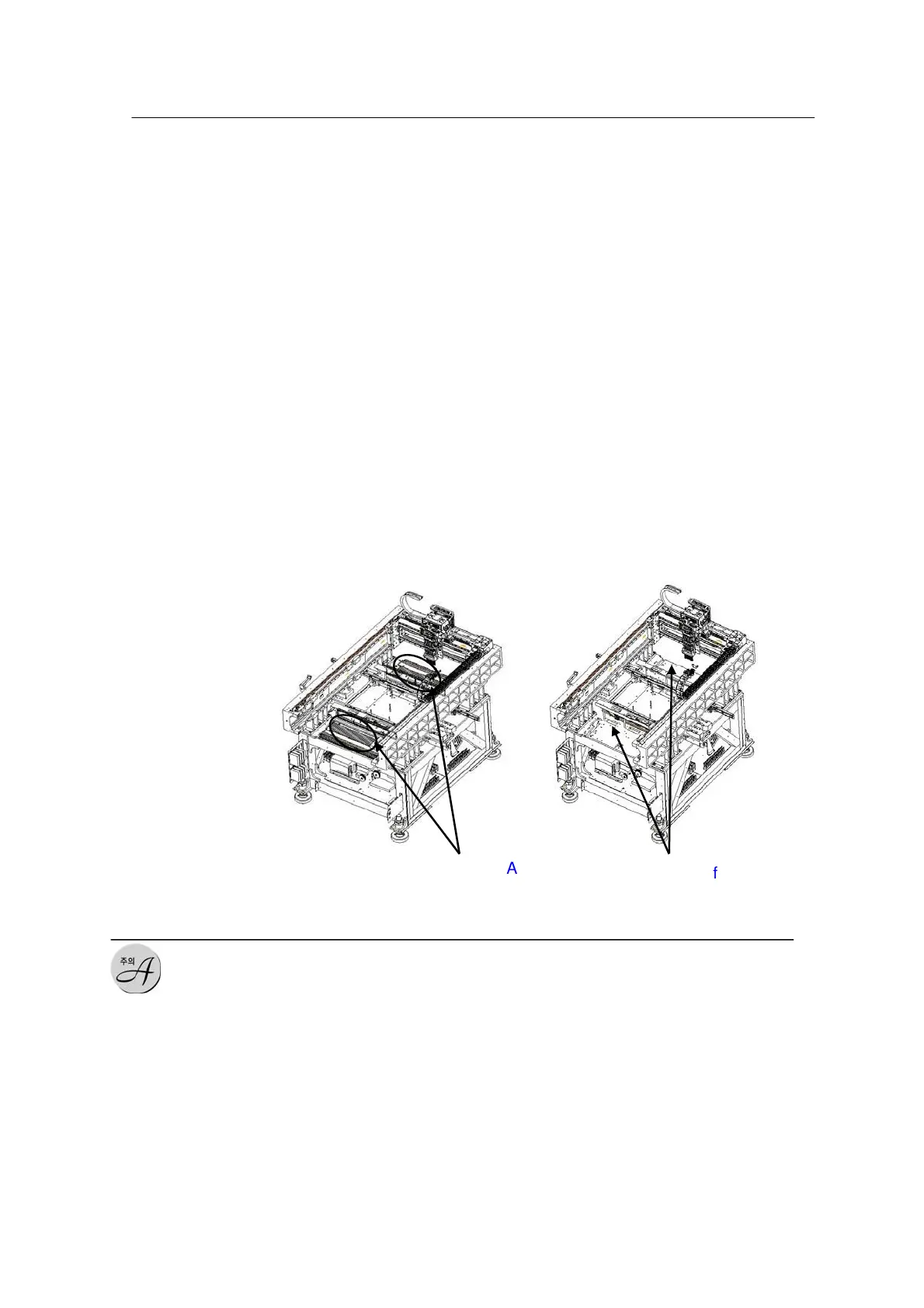

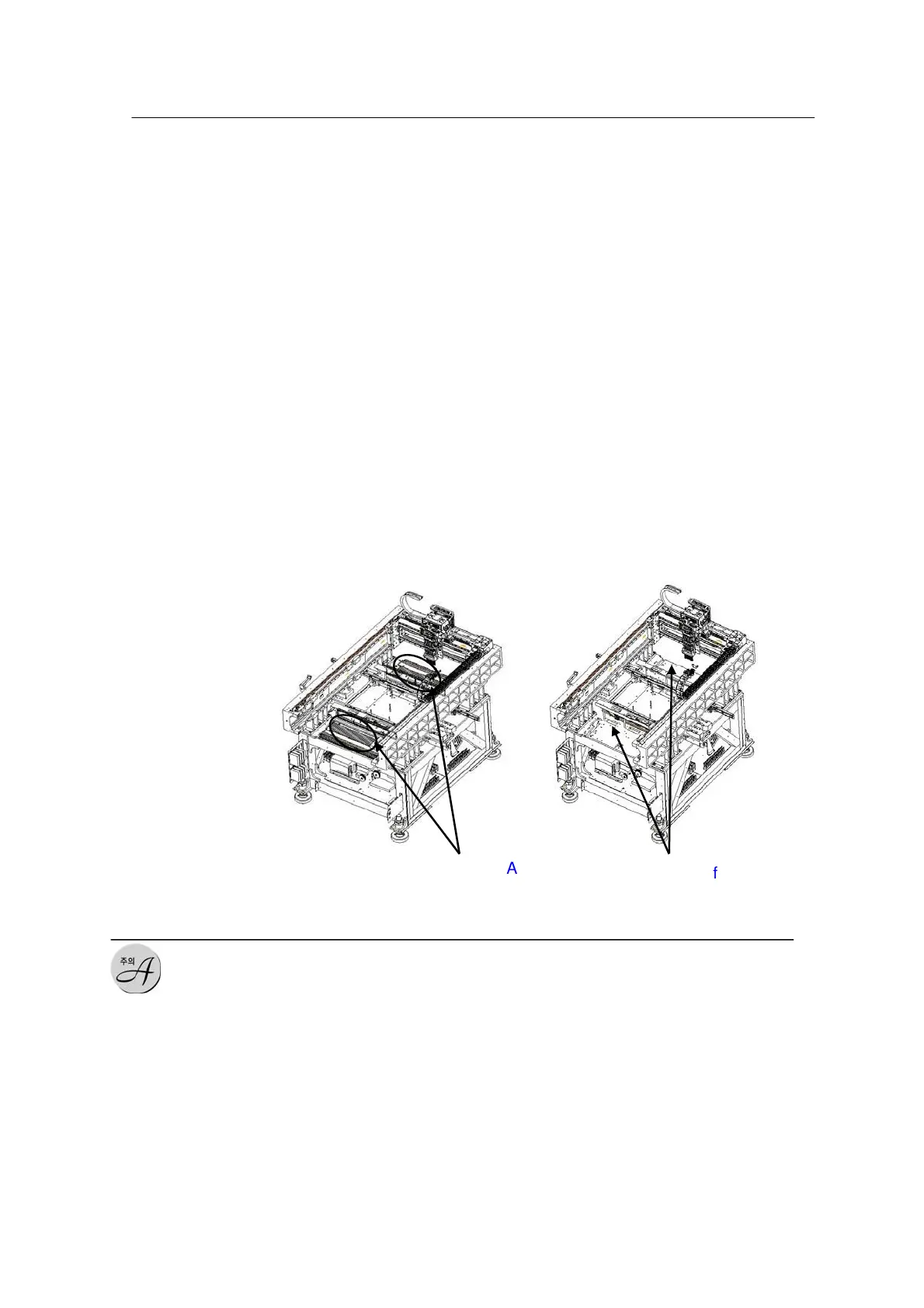

<Base Frame Rack >

The main frame rack is treated with an anti-corrosive coating. However, it

is partially uncoated for the purpose of setup and operation of the

machine. Therefore, the uncoated part must be regularly checked.

2.

Remove the fixation bolt from the Feeder Base Assembly.

Do not touch parts without paining, 3. Check for rust on the exposed part of the main frame rack.

coating and anti-corrosive coating with 4. If rust is found, remove it with a rust remover and wipe the

surface with a dry cloth. bare hands or expose them to water. If parts without paining, coating and anti-corrosive

coating are exposed to foreign materials or water, wipe the surface with a dry towel.

Loading...

Loading...