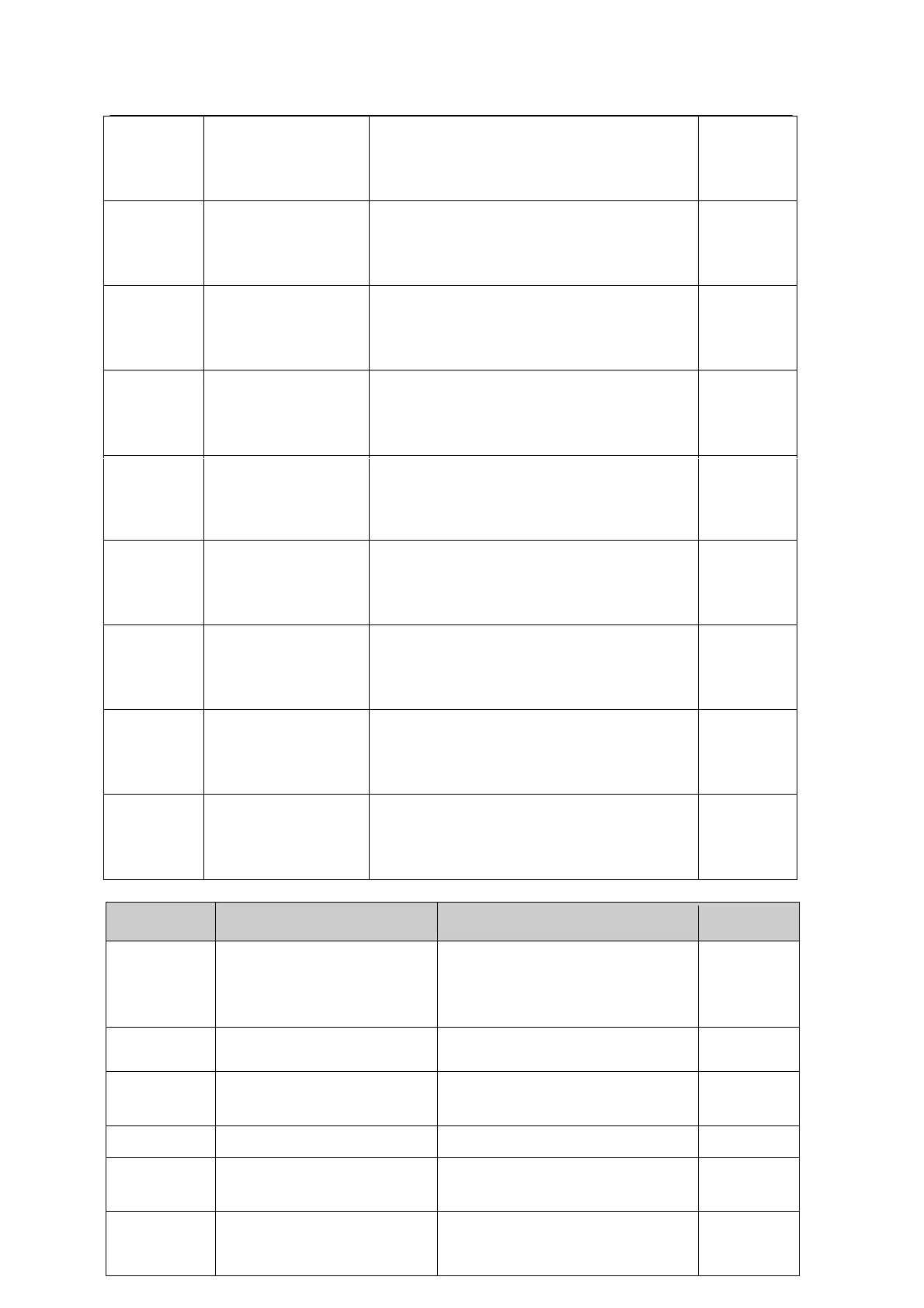

Upper line inspection

error (Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Lower line inspection

error (Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Left line detection

error (Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Right line inspection

error (Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Line detection angle

error (Up-Left)

(Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Line detection angle

error (Up-Right)

(Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Line detection angle

error (Up-Down)

(Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Line detection angle

error (Down-Left)

(Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

Line detection angle

error (Down-Right)

(Centering)

Check illumination, contamination of

component and background and

component DB information and retry

inspection.

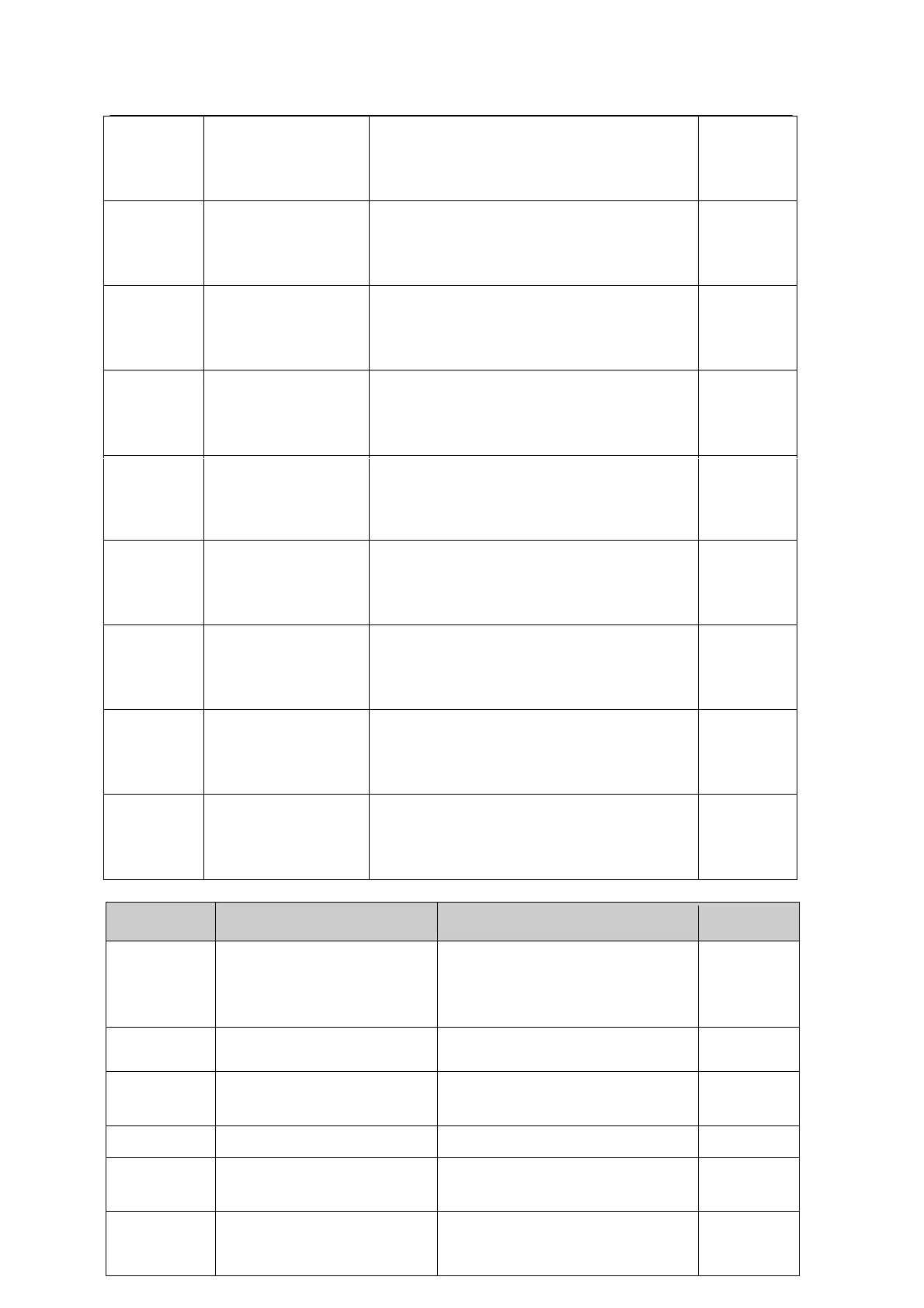

Nozzle is stained with

foreign materials or chip is

detected at the nozzle after

placement.

Check the nozzle.

Carry out cleaning and

maintenance referring to the

nozzle check procedure.

TF rack pallet alignment

error

Align the tray feeder pallet.

Check the location and status of

the Fiducial Mark.

Offset jig ejection error

Axial motion stopped due to

door open

The nozzle is incorrect.

Replace the nozzle with a

correct one.

Check the nozzle.

Check the nozzle setting of ANC.

Loading...

Loading...