WHAT TO DO IF... (troubleshooting guide)

2 Using the transmitter, perform door opening and closing tests and ensure

thatthemovementcorrespondstospecications.

Test several times to assess smooth operation of the door and check for any

defects in assembly or adjustment and any possible points of friction.

3 Checkoperationofallsystemsafetydevicesoneatatime(photocells,sensi-

tive edges, etc.). Photocells: Activate the device during a Closing manoeuvre

and check that the control unit stops the manoeuvre and activates a total

inversionofthemovement(thecourtesylightemits2ashes,twice).Sensi-

tive edges: Activate the device during an Opening or Closing manoeuvre and

check that the control unit stops the manoeuvre and activates a short inver-

sionofthemovement(thecourtesylightemits4ashes,twice).

4 To check the photocells, and to ensure there is no interference with other

devices,passacylinder(diameter5cm,length30cm)throughtheoptic

axisjoiningthepairofphotocells(g. 45):passthecylinderrstclosetothe

TX photocell, then close to the RX and lastly at the centre between the two.

Ensure that in all cases the device engages, changing from the active status

to alarm status and vice versa, and that the envisaged action is generated in

thecontrolunit(forexamplemovementinversionintheClosing manoeuvre).

5 MeasuretheforceasspeciedinthestandardEN12445.Ifthemotorforce

control is used as an auxiliary function for reduction of impact force, test and

identify the setting that obtains the best results.

6 Activate a closing manoeuvre and check impact force of the door against

thetheoorsurface.Ifnecessary,testbydischargingpressuretoobtainthe

best results.

AUTOMATION COMMISSIONING

Commissioning can only be performed after positive results of all test

phases. Partial or “makeshift” commissioning is strictly prohibited.

1 Prepare the automation technical documentation, which must contain the

followingdocuments:Overalllayoutdrawing(seeexampleing. 6, 7, 8),

electricalwiringdiagram(seeexampleinSTEP6), risk assessment and rel-

ativesolutionsadopted(seeformstobecompiledonthewebsitewww.

niceforyou.com), manufacturer’s declaration of conformity for all devices

CAUTION! – All operations in this section must be performed exclusive-

ly by skilled and qualied personnel, in observance of the instructions

in the manual, and current local legislation and safety standards in the

place of installation.

CONNECTING THE AUTOMATION TO THE ELECTRICAL MAINS

CAUTION!– When making this connection, the electrical mains power line

mustbeequippedwithshort-circuitprotectiondevice(betweentheautomation

and the mains).

The electrical mains line must also be equipped with a power disconnect device

(withovervoltagecategoryIII,i.e.minimumgapbetweencontactsof3mm)or

an equivalent system such as socket with removable plug.

This device, when necessary, guarantees fast and safe disconnection of the

power supply and therefore must be placed in a location visible from the auto-

mation. If the power disconnect device is not in the vicinity of the automation

andnotvisiblefromthelatter,itmustbettedwithalockoutfacilitytoprevent

inadvertent or unauthorised connection.

Note – The disconnect devices are not supplied with the product.

AUTOMATION TESTING AND COMMISSIONING

These are the most important phases of automation set-up to ensure maxi-

mum system safety. The testing procedure described can also be performed

as a periodic check of automation devices.

Testing and commissioning of the automation must be performed by skilled

andqualiedpersonnel,whoareresponsibleforthetestsrequiredtoverify

the solutions adopted according to the risks present, and for ensuring obser-

vance of all legal provisions, standards and regulations, and in particular all

requirements of the standard EN 12445, which establishes the test methods

for checking automations for garage doors.

AUTOMATION TESTING

1 EnsurethatallspecicationsinSTEP1regardingsafetyhavebeenstrictly

observed.

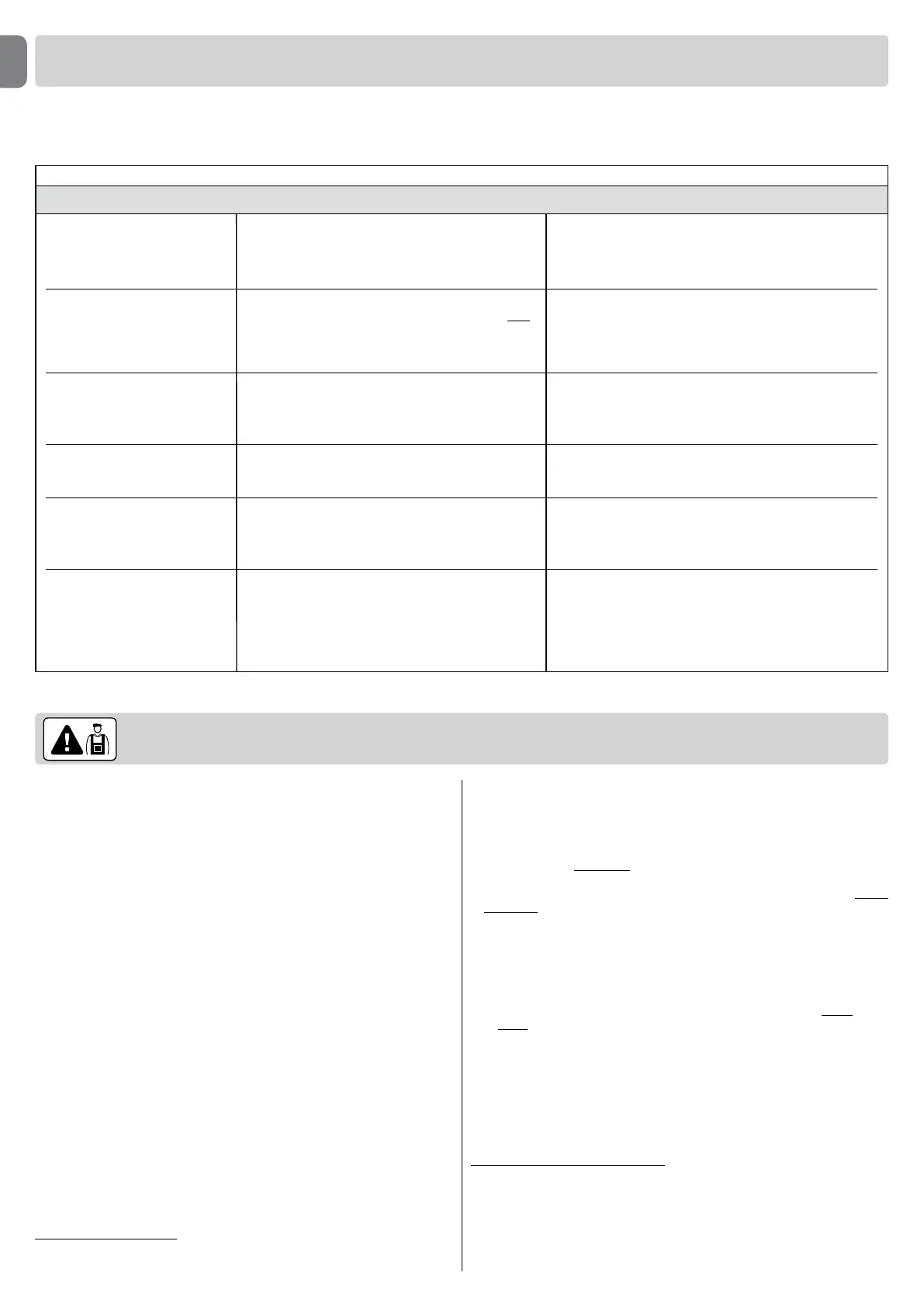

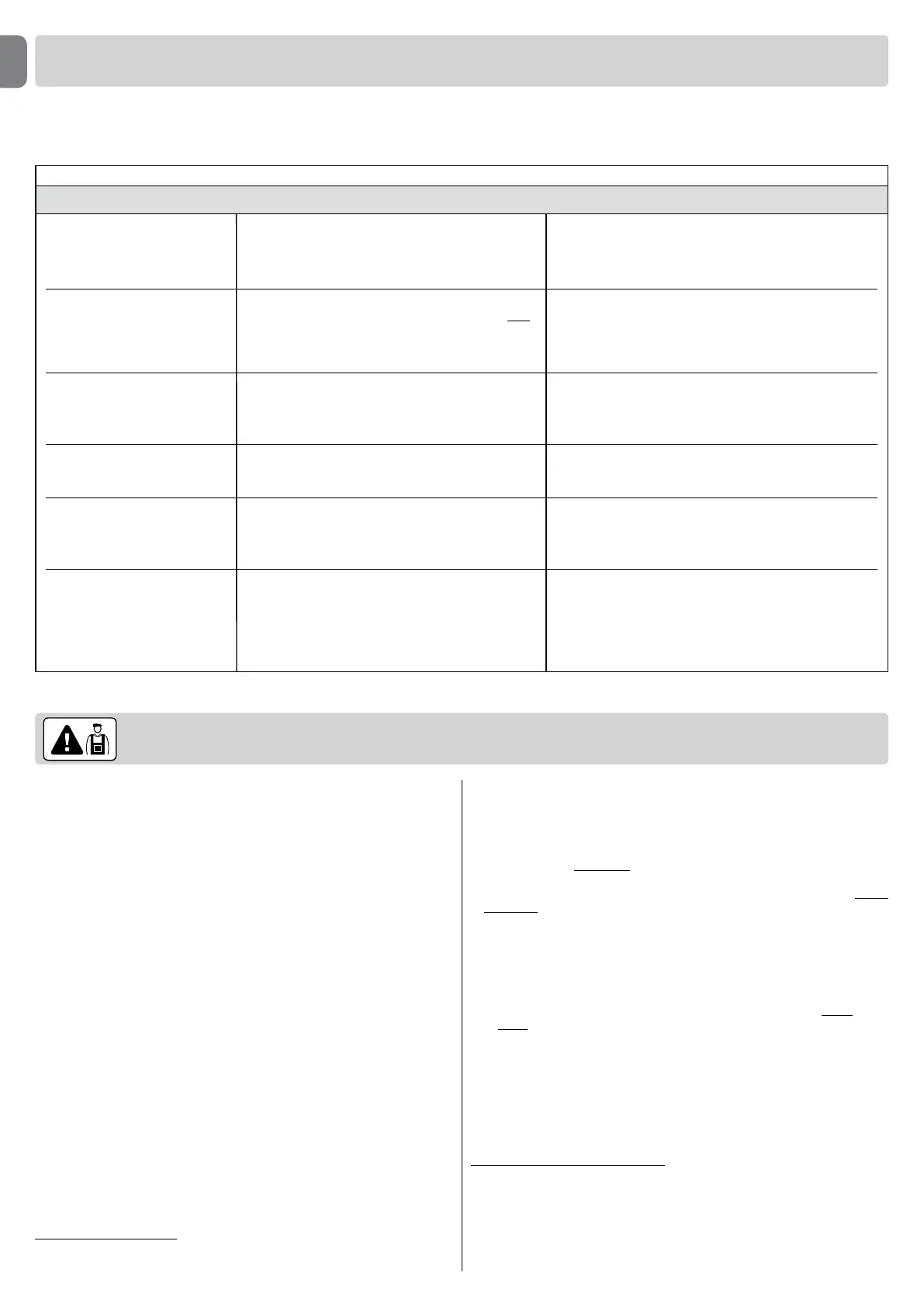

Tasks reserved for qualied technicians

Flashes

2ashes-pause-2ashes

3ashes-pause-3ashes

4ashes-pause-4ashes

5ashes-pause-5ashes

6ashes-pause-6ashes

7ashes-pause-7ashes

Problem

During the Closing manoeuvre, the door stops and

inverts the current movement.

During the Opening or Closing manoeuvre the door

blocks suddenly and the control unit activates a brief

inversion of the manoeuvre in progress

During the Opening or Closing manoeuvre the door

blocks suddenly and the control unit activates a Stop

followed by a brief inversion of movement.

The automation does not respond to commands.

After a series of manoeuvres sent consecutively, the

automation is blocked.

The automation does not respond to commands.

Solution

Thisreactioniscausedbytheactivationofaspecicpair

of photocells in the system, on detection of an obstacle.

Therefore remove the obstacle on the trajectory of these

photocells.

The leafs are subject to increased friction due to a sudden

obstruction(gustofwind,vehicle,personetc.).Ifadjust-

ment to sensitivity is required, refer to the Chapter “Adjust-

ments and other optional Functions”.

Asafetydeviceinstalled(otherthanphotocells,suchassensi-

tive edges) has detected a sudden obstacle.

Therefore remove the obstacle.

Thereisasystemcongurationerror.Deletetheentiremem-

ory of the control unit and repeat installation.

The maximum admissible number of consecutive manoeu-

vres has been exceeded, causing excessive overheating. Wait

for a few minutes to enable the temperature to return below

the maximum limit.

Error in internal electric circuits. Disconnect all power circuits,

wait a few seconds and then re-connect. Retry a command; if

the automation does not respond this may indicate a serious

fault with the electrical board of the control unit or motor wir-

ing. Check and make replacements as necessary.

During normal operation, the control unit constantly monitors the automation processes and is designed to indicate any faults that arise, by means of a pre-set

sequenceofashesemittedbythecourtesylightandredled“L1”onthecontrolunit(thediagnosticsashesalwaysrefertothelastactionperformedbythe

automation).Foranexplanationofthenumberofashesandassociatedcause,refertoTable 6 below:

TABLE 6

8 – English

EN

Loading...

Loading...