STEP 5

5.1 – INSTALLING THE AUTOMATION COMPONENTS

WARNINGS

• Incorrect installation may cause serious physical injury to those

working on or using the system.

• Before starting automation assembly, make the preliminary checks

as described in STEP 3.

After laying the electric cables, proceed with assembly of the mechanical parts

oftheguidesandgearmotor,inthesequencespeciedbelow.

01. Inserttheguideintheseatonthegearmotor(g. 11).

02. Insertthetravellimitmechanicalstop(a) in the guide and move it close

tothegearmotor;thenpositionplate(b) onto the stop and secure the

assemblybymeansofascrew(g. 12). Note – The screw must NOT

be tightened excessively as the limit stop must later be moved to its nal

position.

03. Use two screws to secure the ends of the chain into the groove on the

carriageplate(g. 13).

04. Join the two carriage plates; insert the screw in the support of the drive

pulley; position the drive pulley in the chain and mount the assembly onto

thedrivebracketwiththepinsupplied(g. 14).

05. Insert the chain and carriage inside the guide, taking care to observe the

following:

Fig. 15-a)positionthesideofthecarriagewiththechainxedwiththe

screws on the same side as the contro unit cover;

Fig. 15-b) position the carriage to approx. mid-way on the guide.

06. Pass the chain around the pinion of the gearmotor and close the assembly

withtheprotectioncover(g. 16).

07. Insert the bracket on the end of the guide and secure the two elements by

meansofanutandwasher(g. 17).

08. Tension the chain by tightening the nut on the screw of the drive bracket

(g. 18). CAUTION – if the chain is tensioned excessively, this may

cause excessive stress and damage the gearmotor; if under-ten-

sioned this may cause unpleasant noise.

09.

FOR UP-AND-OVER DOORS ONLY

Ifthedoortobeautomatedis“up-and-over”(projectingornon-pro-

jecting - g. 1), the oscillating arm mod. SPA5 must be tted(g.

19). Then proceed with assembly of the various arm components.

IMPORTANT – Take care to move the arm as close as possible

to the handle of the door.

For assembly of the drive rod, refer to point 10.

Note – for assembly of the accessory, follow the instructions supplied

in the pack.

10. CAUTION! – If the door is up-and-over, use the drive rod supplied

with the oscillating arm for this operation.

Beforettingthedriverod,cutthistoalengththatensuresobservanceof

recommended distance E shown in g. 3. Then use screws and nuts to

secureoneendofthedriverodtothebracket(theonetobexedtothe

doororoscillatingarm)andtheotherendtothecarriage(g. 20).

11. Fix one end of the manual release cord to the carriage and the other end

totheknob(g. 21). Note – Ensure that the manual release knob is posi-

tioned at a maximum height of 180 cm from the ground.

IMPORTANT! – Perform the operations below the door CLOSED

12. • If the door is SECTIONAL: establish the length of distance B consider-

ing the constraints of values A and E(g. 3).

• If the door is UP-AND-OVER: establish the length of distance B con-

sidering the constraints of value F(g. 4).

Note – If values A, E or F allow, the automation can also be xed directly

onto the ceiling (minimum 4 mm).

13. Fold the two ceiling mounting brackets to an “L” and mount in the vicinity

ofthegearmotor,bymeansofscrewsandnuts(g. 22).

Note – choose the most suitable hole on the brackets to observe distance

B selected in point 12.

5.2 – FIXING THE AUTOMATION TO THE WALL, CEILING, AND

DOOR

Afterassemblyoftheguideandgearmotor,xtheautomationtothewall,ceil-

ing and door as follows.

01. Usingasuitablemeansofsupport(ladder,polesorsimilar)liftthegearmotor

from the ground an position at the required height so that the guide brackets

areplacedagainsttheceilingandwallabovethedoor(g. 23). IMPOR-

TANT – (g. 23-a) align the guide and gearmotor with the vertical axis of

the door and perpendicular to the latter (90° angle). Note – In the ca se of

up-and-over doors, the guide must be aligned with the oscillating arm.

Also ensure observance of the values A, B, E in g. 3 and values B, F in

g. 4.

02. Check the position of the guide, which must be perfectly horizontal, and

markthe4bracketxturepoints,afterwhichdrilltherelativeholesand

inserttheplugs(g. 24).

03. Fix the automation to the ceiling and wall using screws and plugs suited to

thesupportmaterial(g. 26).

Notes:

• Depending on the type of wall, the bracket at the end of the guide can

be xed by means of the rivets or screws and plugs.

• Take care when choosing the method of bracket xture to the ceiling,

taking into account the following:

– the bracket at the end of the guide must withstand the force required to

open and close the door;

– the ceiling mounted brackets must withstand the weight of the gearmotor.

In both cases possible wear and deformation over time must be taken into

account.

04. Use a saw to cut off the excess section of the ceiling-mounted brackets

(g. 26).

05. (With the door closed) Pull the release knob and slide the carriage until the

anchoring bracket is positioned on the upper edge of the sectional door,

oruntilitreachestheconnectionoftheoscillatingarm(up-and-overdoor).

Thenalignthedriverodalongthetrajectoryoftheguideandxthebracket

tothedoorusingrivetsorscrewssuitedtothedoormaterial(g. 27).

INSTALLATION: COMPONENT ASSEMBLY

AND CONNECTIONS

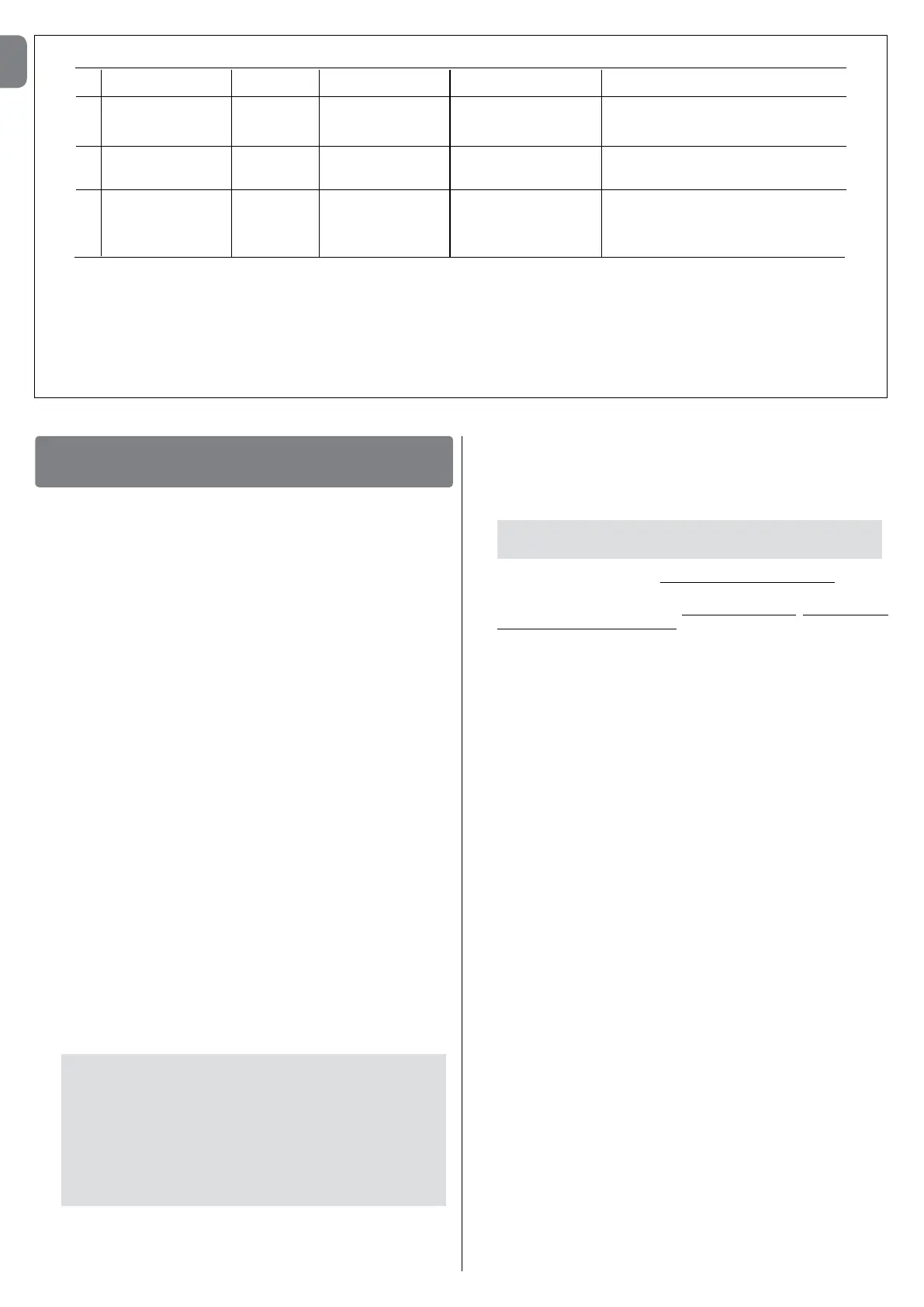

Note 1 – The cables required for the set-up of the system (not included in the pack) may vary according to the quantity and type

of devices envisaged for the installation.

Note 2 – The connections to terminals 1-2 (Stop), 4-5 (Step-step) and 3-5 (Photo) can be made using a single cable with several

internal wires.

CAUTION! –

The cables used must be suited to the installation environment; for example a cable type H03VV-F for indoor

environments is recommended.

Technical specications of electric cables(note 1)

Devices

Safety

photocells

Control

pushbutton

Safety pushbutton

– sensitive edges

– etc.

Terminals

3 - 5

3 - 4

1 - 2

Maximum admissible length

20m(note 2)

20m(note 2)

20m(note 2)

20m(note 2)

Function

PHOTO input

Input

STEP-STEP

STOP Input

Cable type

TX Cable 2 x 0,25 mm

2

RX Cable 3 x 0,25 mm

2

Cable 2 x 0,25 mm

2

Cable 2 x 0,25 mm

2

4 – English

EN

A

B

C

Loading...

Loading...