54

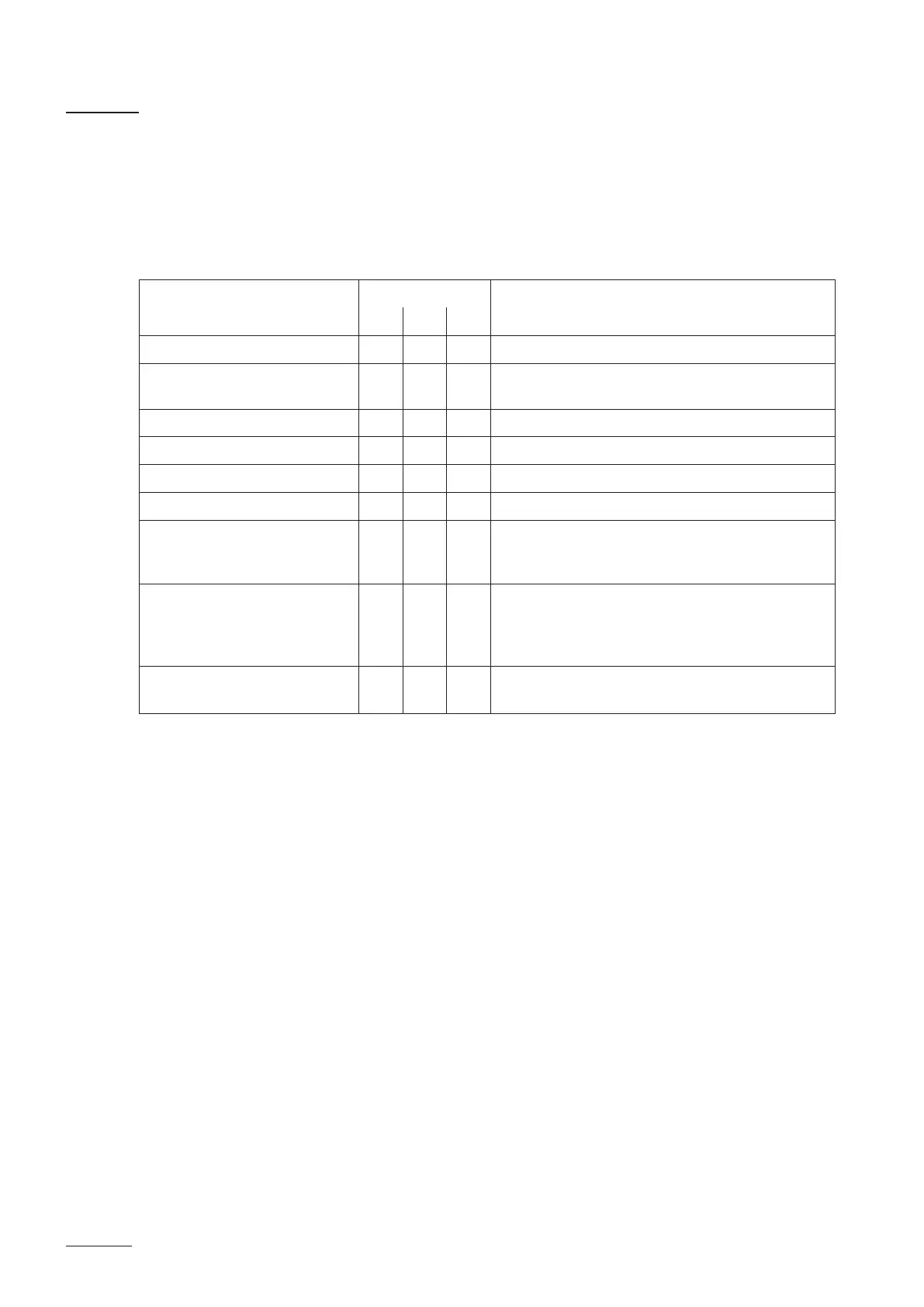

6.2 Maintenance list

To maintain operational safety the Nordmann AT4 D steam generator must

be maintained at regular intervals. This is differentiated between the first

maintenance after approx. 500 operating hours (I), steam cylinder re-

placement after the yellow LED lights (II) and annual maintenance (III).

Below you will nd a summary of the work to be carried out for each of the

three maintenance stages.

Components Interval Work to be done

I II III

Steam cylinder X Remove and replace.

Drain pump X Remove, disassemble and clean, replace if neces-

sary.

Steam cylinder receptacle X Inspect, clean if necessary.

Inlet valve X Remove and clean lter insert, replace if necessary.

Drain cup X Remove and clean if necessary

Drain pipe and siphon X Inspect, clean if necessary (decalcify and rinse out).

Steam installation X X Inspect steam and condensate hoses for cracks and

to see that they are correctly attached, replace faulty

hoses.

Water installation X X Inspect water hoses in the unit for cracks and to see that

they are correctly attached, replace faulty hoses.

Check supply pipe is tight, make tight if necessary.

Clean water lter, if available.

Electrical installation X X Check all cables in the unit are rmly positioned and

examine status of insulation.

Loading...

Loading...