Troubleshooting

5-3

Part 1612500−02

E 2018 Nordson Corporation

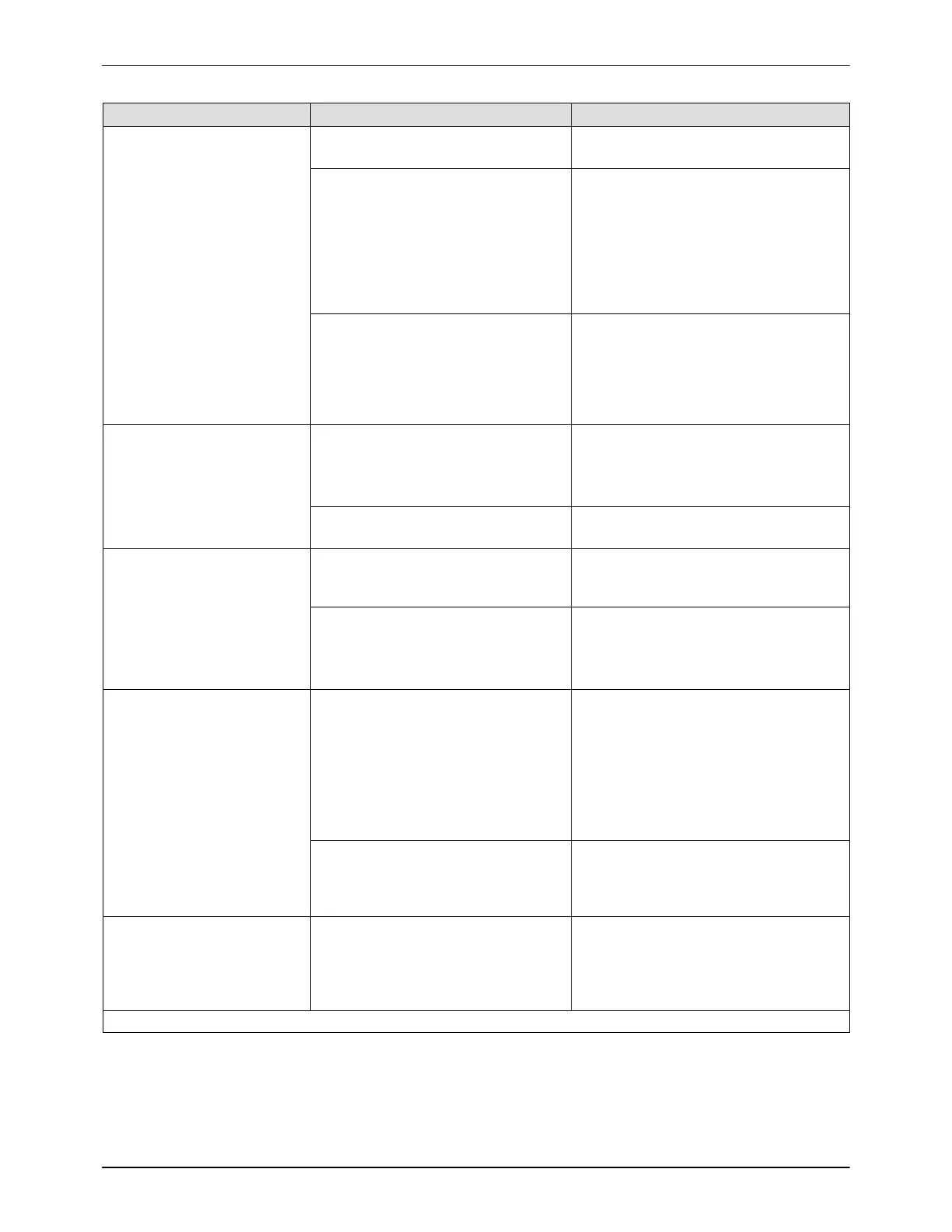

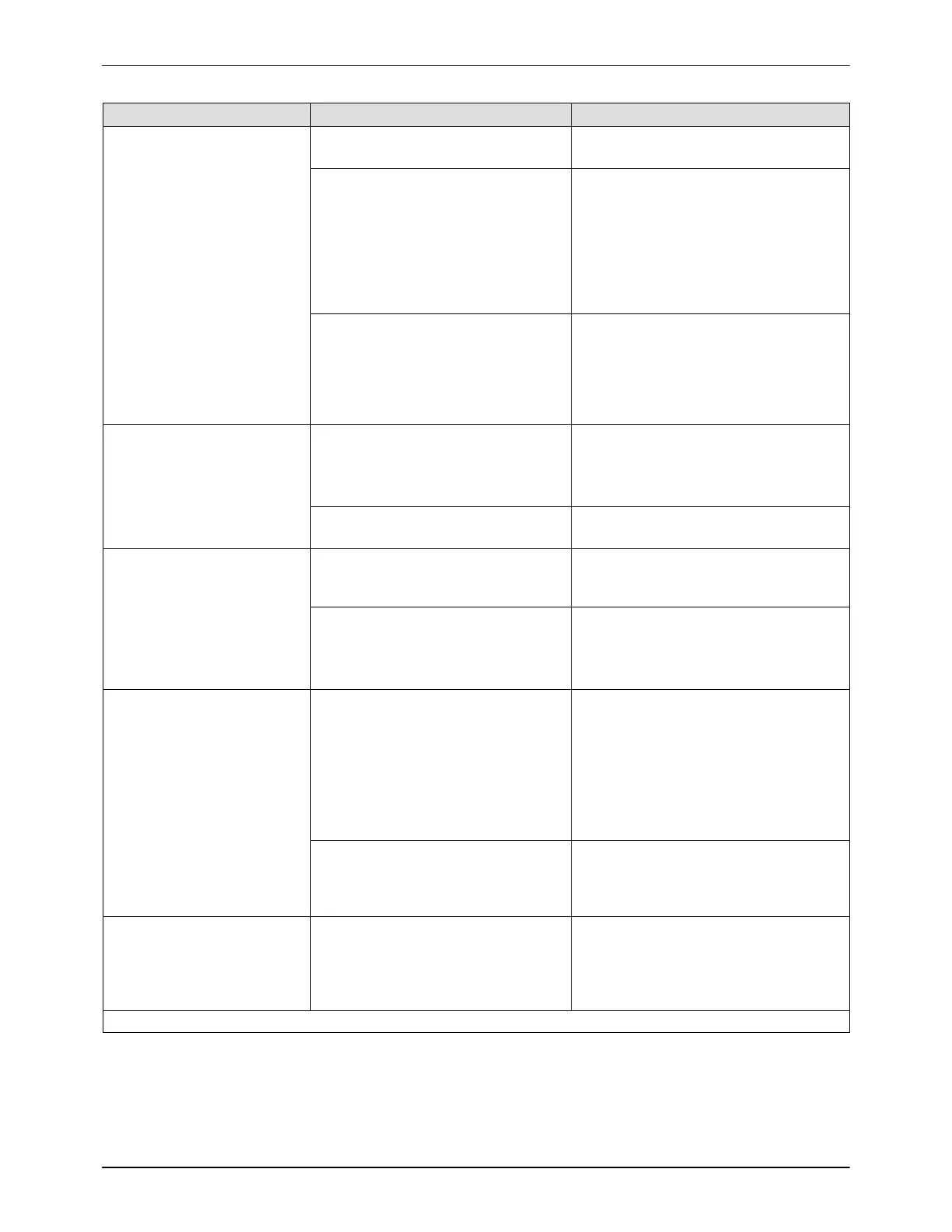

Corrective ActionPossible CauseProblem

3. Loss of wrap, poor

transfer efficiency

Low electrostatic voltage Increase the electrostatic voltage.

Poor electrode connection Remove the nozzle and electrode

assembly. Clean the electrode and

check for carbon tracking or damage.

Check the electrode resistance as

shown on page 5-7. If the electrode

assembly is good, remove the gun

power supply and check its

resistance as shown on page 5-7.

Poorly grounded parts Check the conveyor chain, rollers,

and part hangers for powder buildup.

The resistance between the parts

and ground must be 1 megohm or

less. For best results, 500 ohms or

less is recommended.

4. No kV output from the

spray gun (kV=0),

powder is spraying

Damaged gun cable Perform the Gun Cable Continuity

Checks on page 5-8.

If an open or short is found, replace

the cable.

Spray gun power supply shorted Perform the Power Supply

Resistance Test on page 5-6.

5. No kV output from the

spray gun (mA=0),

powder is spraying

Spray gun power supply open Perform the Power Supply

Resistance Test on page 5-6.

Damaged gun cable Perform the Gun Cable Continuity

Test on page 5-8.

If an open or short is found, replace

the cable.

6. No kV output and no

powder output

Malfunctioning trigger switch or

cable

Check the trigger LED on the

controller interface. If the LED is not

lit, check the switch connection to the

gun cable.

Perform the Gun Cable Continuity

Test on page 5-8. If the cable and

connections are good, replace the

switch.

Controller configured for automatic

operation

Cycle controller power. If A appears

on the kV/uA display, remove the

main control board and move the JP1

jumper to the Manual position.

7. Powder build up on

the electrode tip

Insufficient electrode air wash flow

due to low input pressure or

blockage in manifold orifice

Check input air pressure. Remove

electrode air wash connector and

check manifold orifice for blockage.

Orifice size is .25−.3 mm. Clean with

an appropriate tool.

Continued...

Loading...

Loading...