System Setup

2-8

Part 1612500−02

E 2018 Nordson Corporation

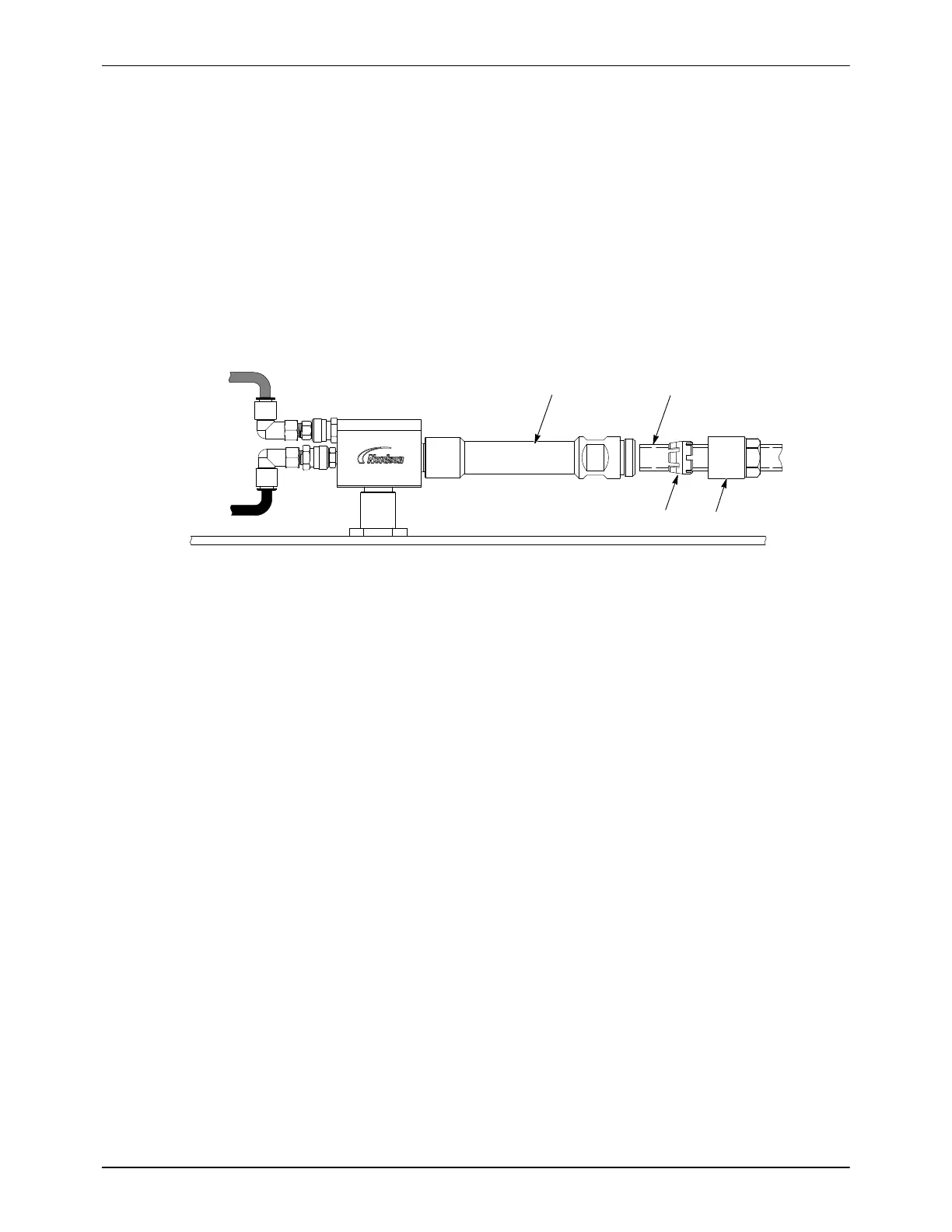

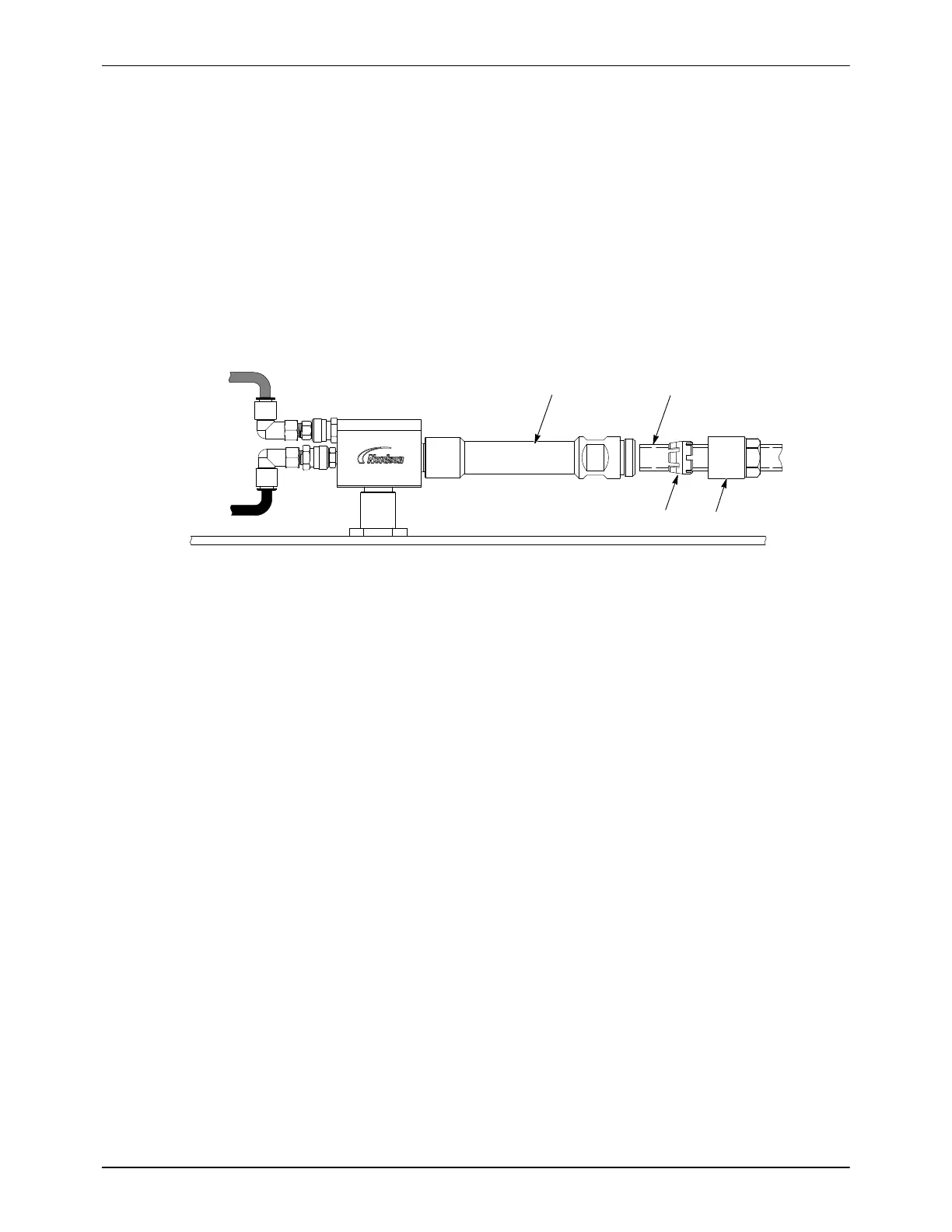

Connecting the Powder Hose to the Pump

1. Remove the nut (4) and sleeve (3) from the throat holder (2). Slide them

both over the end of the powder hose (1). Make sure the end of the

powder hose is cut straight.

2. Insert the powder hose into the throat holder until it bottoms out on the

ceramic sleeve inside the holder.

3. While holding the hose in place, slide the sleeve and nut down the hose

and start threading the nut onto the throat holder.

4. Use a 12-point 15/16 in. flare nut wrench to tighten the nut until it

bottoms out against the throat holder. Refer to Optional Tools for the

wrench part number.

2

3

4

A

F

1

Figure 2-8 Connecting the Powder Hose to the Pump

1. Powder hose

2. Throat holder

3. Sleeve 4. Nut

Bundling Tubing and Cable

Use the sections of black spiral-cut tubing supplied with the system to

bundle together the spray gun cable, air tubing, and powder hose. Coil the

bundled tubing and cable and hang the coil on the hook at the back of the

cart tower.

System Air Connections

System Air Supply

Compressed air should be supplied from an air drop equipped with a

self-relieving shutoff valve. The air must be clean and dry. A refrigerant or

desiccant-type air drier and air filters are recommended.

All systems are shipped with a 0.3-micron air filter. It is important that the

filter be used to prevent contamination of the system pneumatic

components and the powder supply.

Supply air pressure should be 4.0−7.6 bar (58−110 psi).

Loading...

Loading...