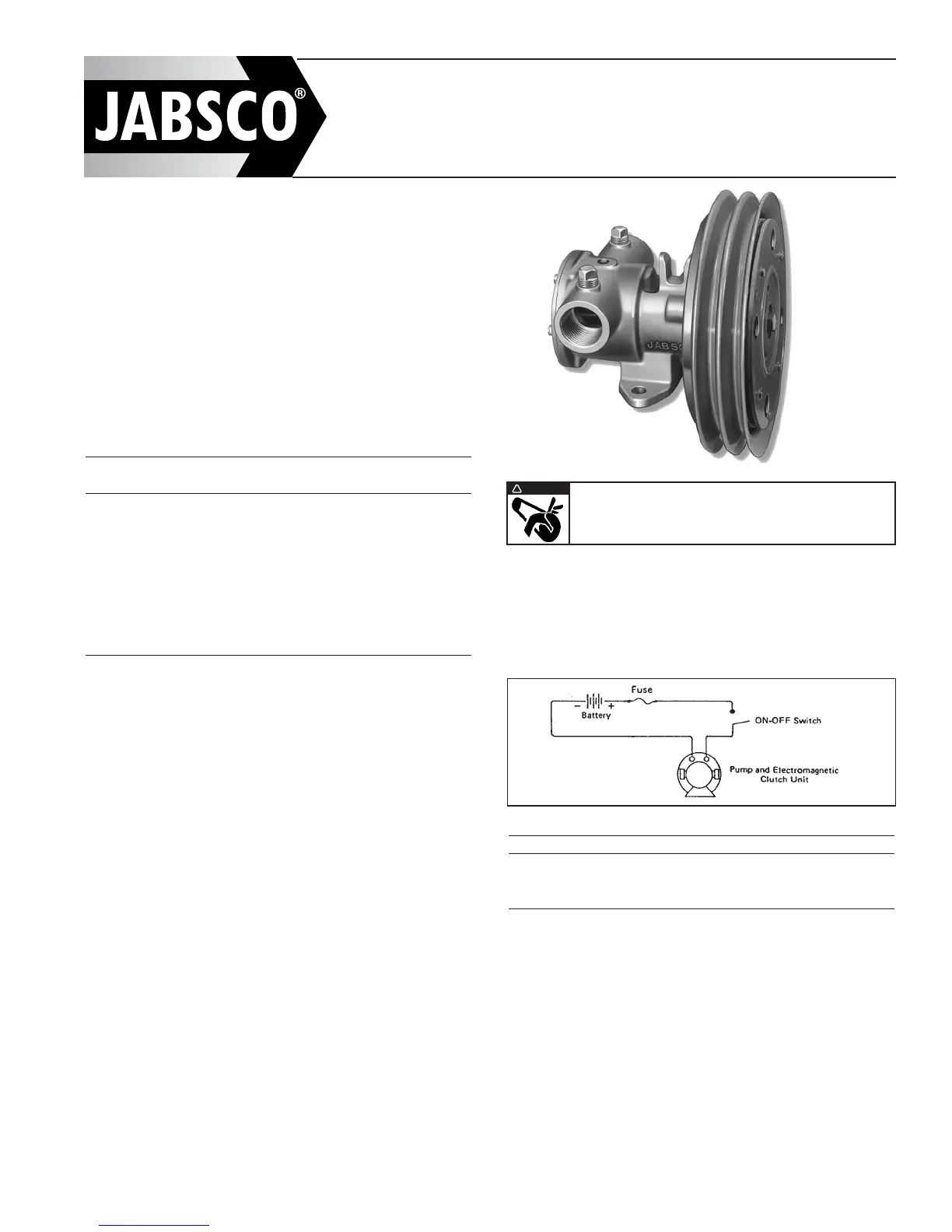

Models 11860-Series

11870-Series

Models 11860, 11870-Series

SELF-PRIMING PUMPS

ELECTRO-MAGNETIC CLUTCH UNIT

FEATURES

Body: Bronze

Impeller: Nitrile

Shaft: Stainless Steel

Seal: Carbon-Ceramic, Face Type

Ports: 11860-Series, 1" NPT Internal

11870-Series, 1-1/4" NPT Internal

Bearings: Shielded Ball Bearings

Weight: 11860-Series, 15 lb (6.8 kg) Approx.

11870-Series, 19-1/2 lb (8.9 kg) Approx.

Clutch

Model Volt/Belt Cam Impeller Insert

11860-0005 12 / 2-A Brass Nitrile Brass

11860-0045 12 / 1-B Brass Nitrile Brass

11860-0006 24 / 2-A Brass Nitrile Brass

11860-0046 24 / 1-B Brass Nitrile Brass

11870-0005 12 / 2-A Brass Nitrile Brass

11870-0045 12 / 1-B Brass Nitrile Brass

11870-0006 24 / 2-A Brass Nitrile Brass

11870-0046 24 / 1-B Brass Nitrile Brass

11870-0007 32 / 2-A Brass Nitrile Brass

APPLICATION

MARINE: Pumping bilges, Washdowns, Circulating

water in bait tanks, Utility dock-side pump.

INDUSTRIAL: Circulating and transferring, Velocity-

mixing, Pumping machine tool coolants, Return spill,

Sump drainage, Chemicals, Pharmaceuticals, Soap,

Liquors, Ink, Dyes, Alcohol, Various acids, Tanning

Liquors, Glycerine, Brine, etc.

FARMING: Pumping water stock, Pumping water from

shallow wells and cisterns.

PLUMBING AND HOME EMERGENCY USE: Pumping

out flooded basements, Cesspools, Sumps, Water

heaters and water closets, Drains and sinks, Draining

fishponds and pools.

PUBLIC UTILITIES AND MUNICIPALITIES: Under the

hood mounting on service trucks for draining meter

boxes, manholes, excavations; For pollution control and

watering for dust control.

INSTALLATION

Pump may be mounted in any position. Intake and

discharge ports are determined by the direction of shaft

rotation (refer to dimensional drawing). Before installing,

energize clutch and turn pump shaft in direction of shaft

rotation. Drive pump with two “A” size belts or one “B”

size belt. Avoid dry-running by using Vacuum Switch

Model 4732-0000 for automatic shutoff.

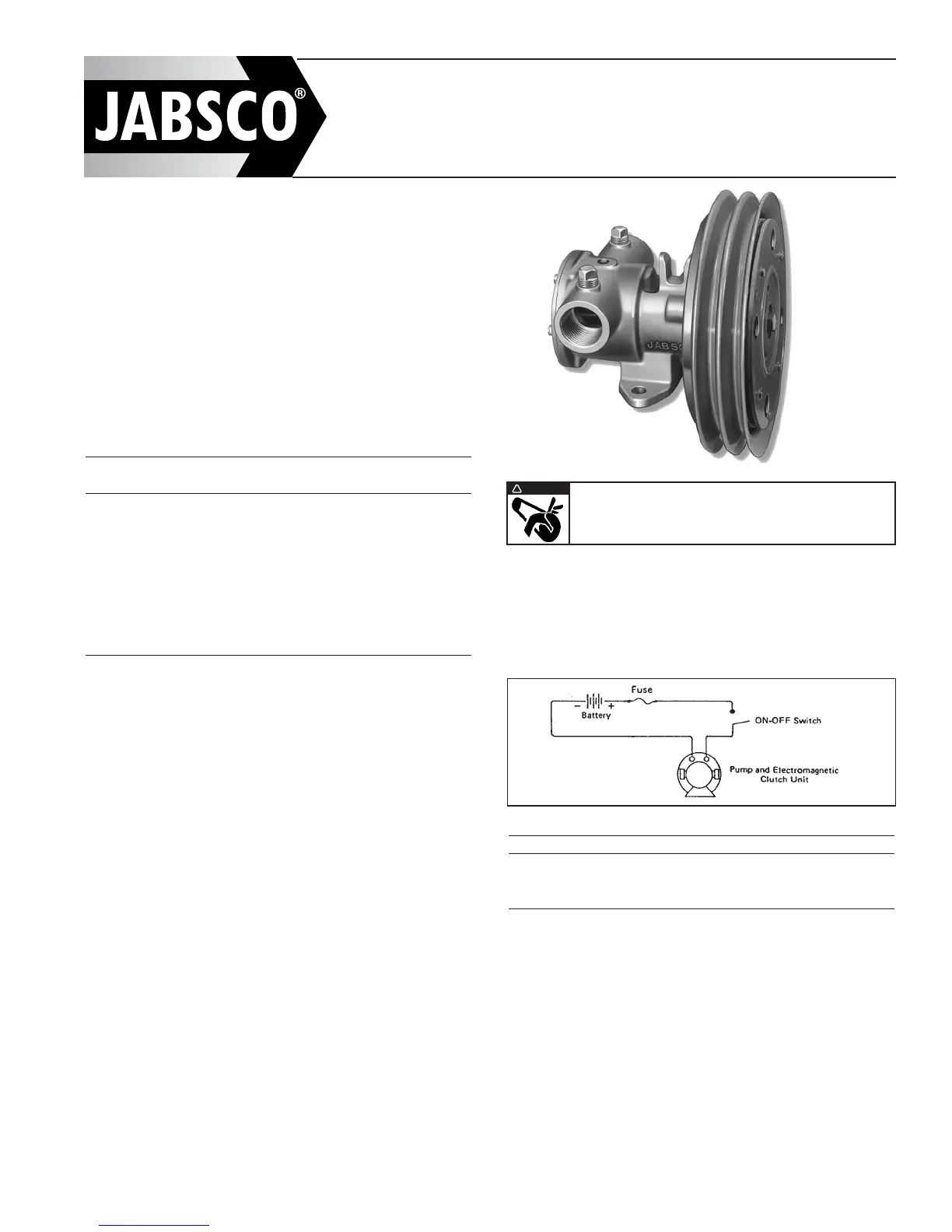

WIRING

Connect wires as shown for manual on-off operation. Install

appropriate size fuse (see Electrical Specification Chart) in

positive lead as close to power source as possible. For

complete wiring instruction, see diagram on last page.

Connect wires as shown for manual on-off operation.

ELECTRICAL SPECIFICATIONS

Voltage Amp Draw Fuse Size

12 4 7

24 2 4

32 1.5 2

OPERATION

Pump will self-prime at low or high speeds. Make sure

that all connections are airtight. 12 Volt models are

equipped with mechanical clutch engagement screws in

case of electrical failure. To mechanically engage clutch,

loosen locking nuts, tighten allen head screws and

retighten locking nuts. Reverse procedure to disengage

clutch. If the mechanical engagement feature is not

desired, the screws may be removed. DO NOT RUN

PUMP DRY FOR MORE THAN 30 SECONDS. LACK

OF WATER FLOW MAY DAMAGE IMPELLER. To drain

pump, loosen end cover screws. See Head Capacity

Table for head pressures and flow. To avoid costly

shutdowns, keep a Jabsco Service. Kit on hand.

Loading...

Loading...