Noise Width

Set the width for judging noise.

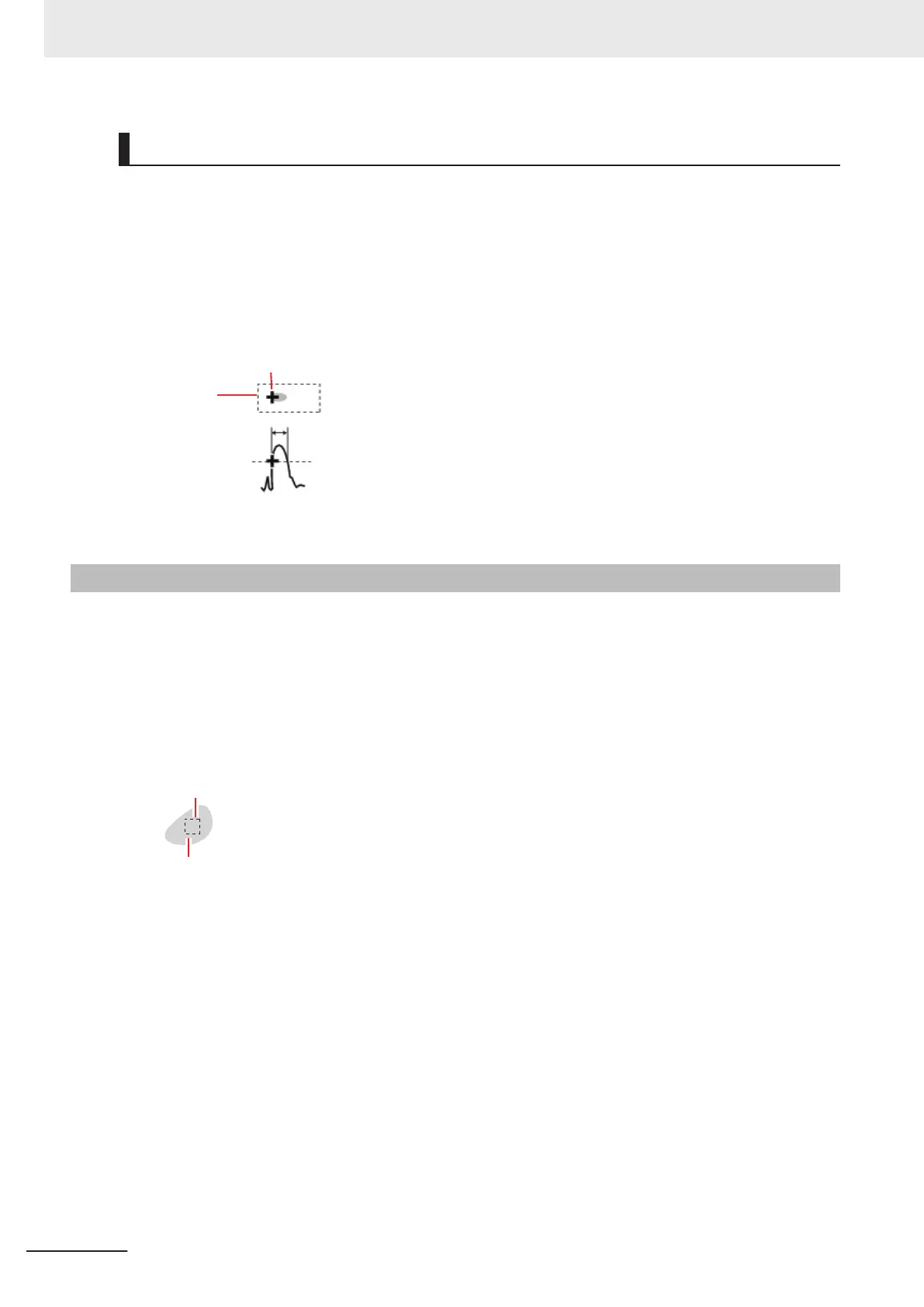

• When no color is specified:

If another edge is detected within the width range starting from the point where an edge was first

detected, the newly detected point is considered noise.

• When a color is specified:

If the color difference distributions again falls below the edge level within the width range starting

from the point where an edge was first detected, the newly detected point is considered noise.

Edge detection point

Measurement

region

If the value is below the edge level within the

specified width, it is considered as noise.

Noise width (pixels)

Edge level50%

When points are mistakenly detected as edges due to noise, increase the color difference value.

A-5-4

Defect Detection Measurement

Color changes within the measurement region are used to find defects such as scratches,contamina-

tion, and chipping.

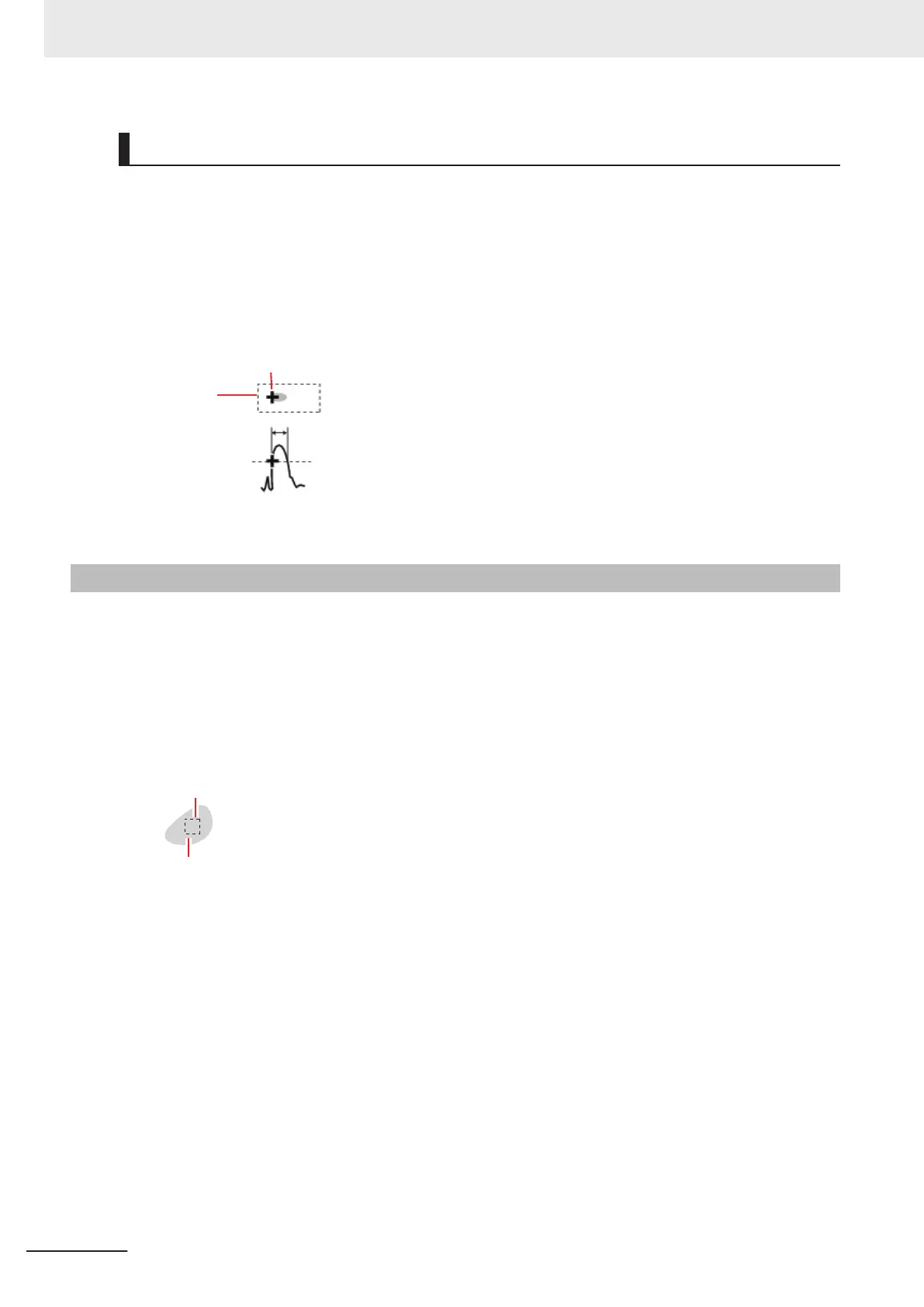

After measurement region is drawn, a rectangle (defect detection region) is automatically formed in

this region. While moving the defect detection region around, calculate average density for each area

to determine the difference between the original area and the surrounding area. This difference is

called the defect level. Calculate the defect level for all defect detection areas. If the maximum value

exceeds the judgement value, it is judged that there are defects in the measurement region.

Defect detection size

Defect

Increasing Defect size allows for shortening of processing time, but this will reduce measurement ac-

curacy.

Appendices

A - 18

FH/FHV Series Vision System User’s Manual (Z365-E1)

Loading...

Loading...