2-399

2 Instruction Descriptions

NJ-series Instructions Reference Manual (W502)

Conversion Instructions

2

PIDAT

z ATDone (Autotuning Normal Completion)

This flag indicates when autotuning was completed normally. It changes to TRUE when autotuning

is completed normally and remains TRUE as long as the value of StartAT is TRUE. It is FALSE in the

following cases.

• An autotuning error end occurred.

• Autotuning is in progress (i.e., while the value of ATB usy is TRUE).

• PID control is in progress without autotuning.

• PID control is not in progress (i.e., the value of Run is FALSE).

• The value of StartAT is FALSE.

z ATBusy (Autotuning Busy)

This flag indicates when autotuning is in progress. It is TRUE while autotuning is in progress. Other-

wise it is FALSE.

z MV (Manipulated Variable)

This is the manipulated variable that is applied to the controlled system.

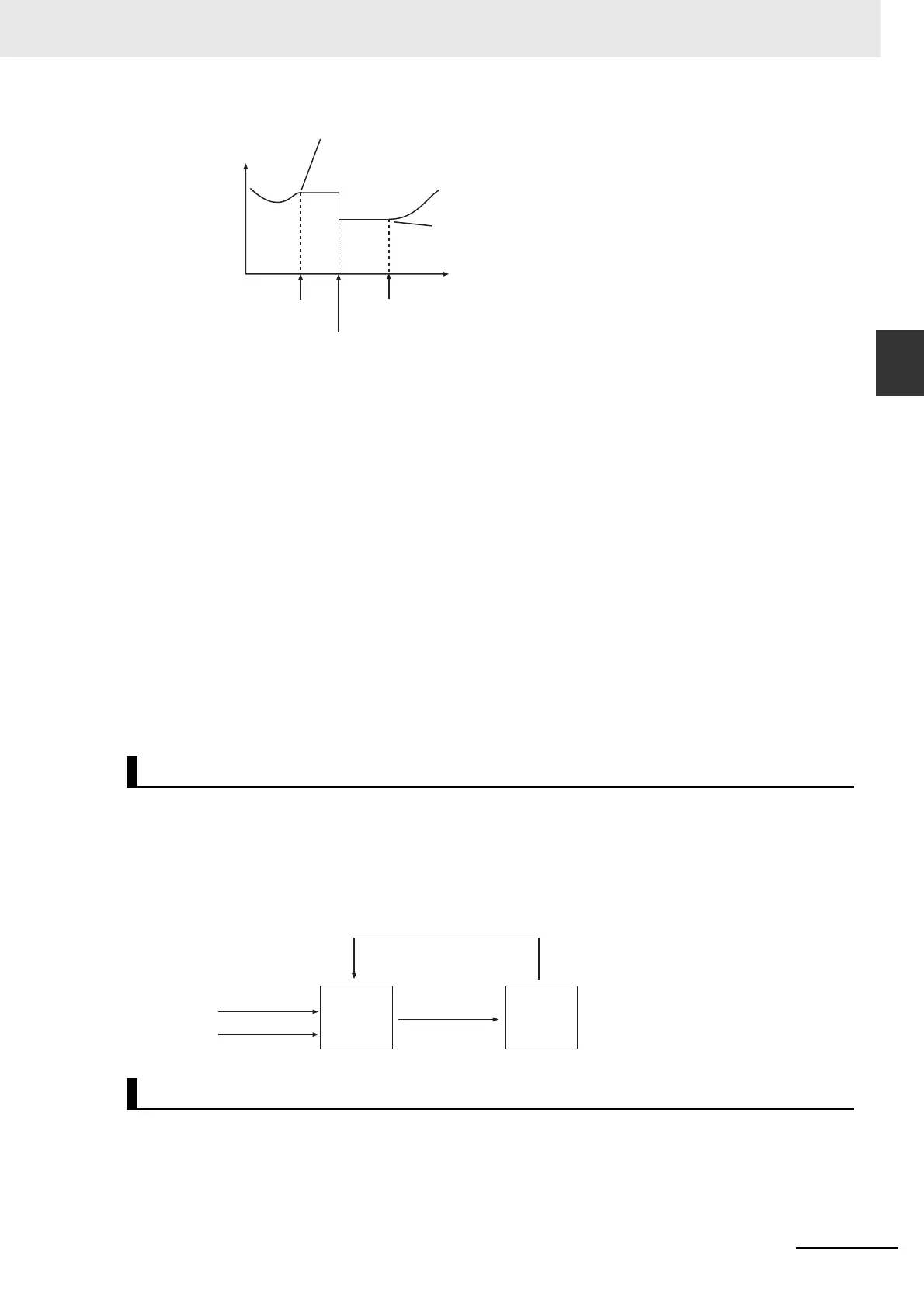

PID control is a feedback control method that repeatedly measures the process value of the controlled

system and calculates a manipulated variable so that the process value approaches a set point. This

instruction therefore outputs a manipulated variable for the following inputs: process value, set point,

and calculation parameters. PID control periodically measures the process value, calculates the manip-

ulated variable, and outputs the manipulated variable so that the process value approaches the set

point.

PID control is performed by combining the proportional action, integral action, and derivative action.

These actions are described next.

Introduction to PID Control

Proportional (P), Integral (I), and Derivative (D) Actions

Time

ManCtl changed to TRUE.

ManCtl changed to FALSE.

Value of MV from automatic operation used.

Value of MV from manual operation used.

Value of ManMV changed.

MV

Set point

Manipulated

variable

Process value

Repeatedly executed.

Parameters

PID

processing

Controlled

system

Loading...

Loading...