2 Instruction Descriptions

2-404

NJ-series Instructions Reference Manual (W502)

You must use suitable PID constants to execute this instruction. There are the following two ways to

achieve this.

z When Suitable PID Constants Are Not Known

Perform autotuning at the start of operation to find suitable PID constants. Change the value of Run

to TRUE while the value of StartAT is TRUE. First, autotuning is executed, and then PID control is

started with the PID constants that are found.

z When Suitable PID Constants Are Known

Set suitable PID constants in ProportinalBand, IntegrationTime, and DerivativeTime, and then

change Run to TRUE. ProportinalBand, IntegrationTime, and DerivativeTime are in-out variables.

You cannot set constants for the input parameters. Always define suitable variables, and then assign

the values to input parameters.

You can change the PID constants during operation. You can also perform autotuning during opera-

tion. To start autotuning during operation, change the value of StartAT to TRUE.

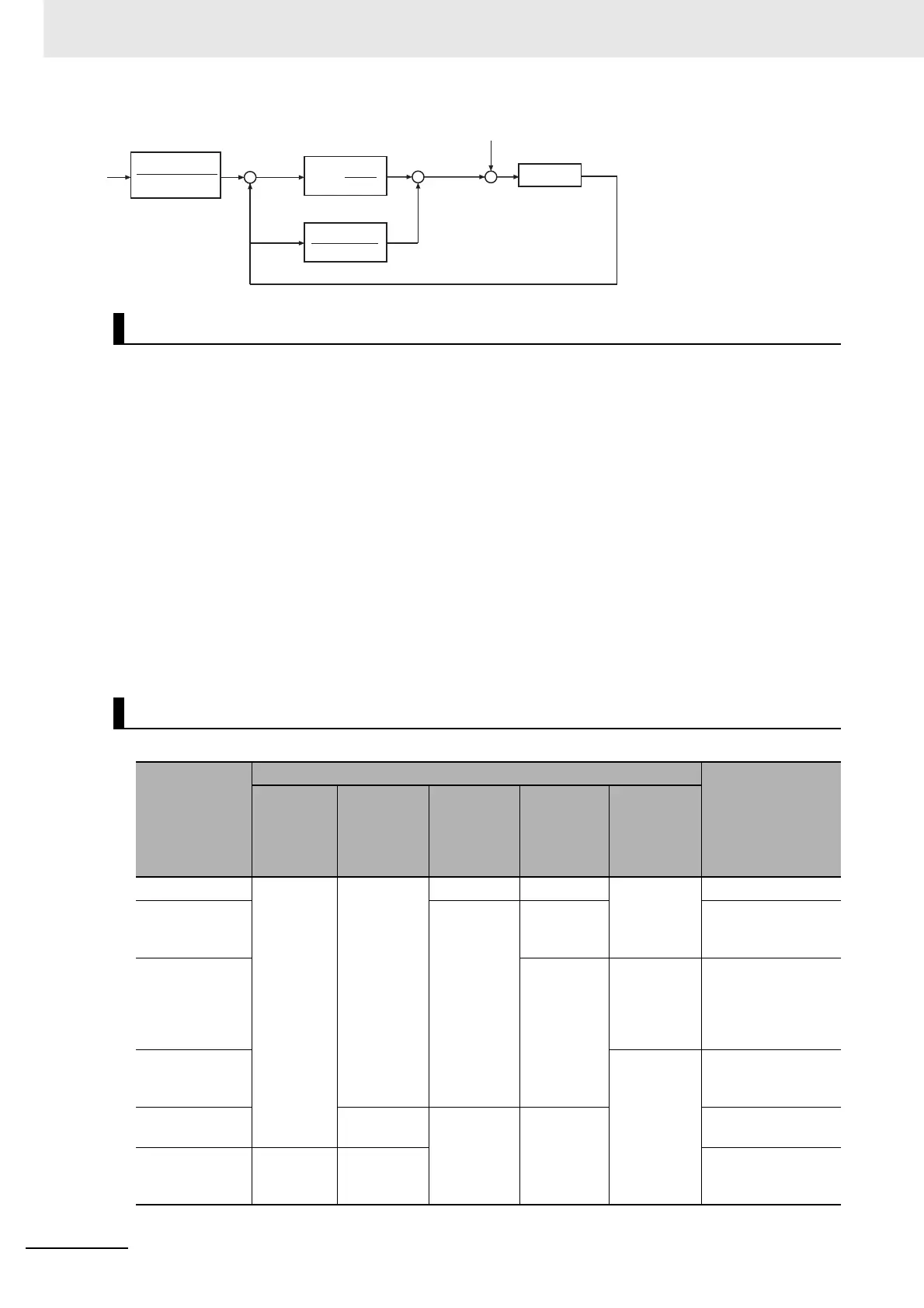

Manipulated variable MV is determined according to the control status as shown in the following table.

Starting PID Control

Control Status and Manipulated Variable

Control status

Value of variable

Manipulated vari-

able MV

ManCtl

(man-

ual/auto

control)

Run (exe-

cution con-

dition)

Error (error

end)

Man-

TrackSw

(manual

tracking

switch)

ATBusy

(autotun-

ing busy)

Error end

FALSE

TRUE

TRUE

---

FALSE

ErrorMV (error MV)

MV tracking dur-

ing automatic

operation

FALSE

TRUE MVTrackVal (MV

tracking value)

Autotuning dur-

ing automatic

operation

FALSE TRUE Value repeatedly

changes between

upper limit of MV

and lower limit of

MV.

Not autotuning

during automatic

operation

FALSE Value calculated

with current PID

constants.

Instruction exe-

cution stopped

FALSE ---

---

StopMV (Stop MV)

Manual opera-

tion

TRUE --- ManMV (manual

manipulated vari-

able)

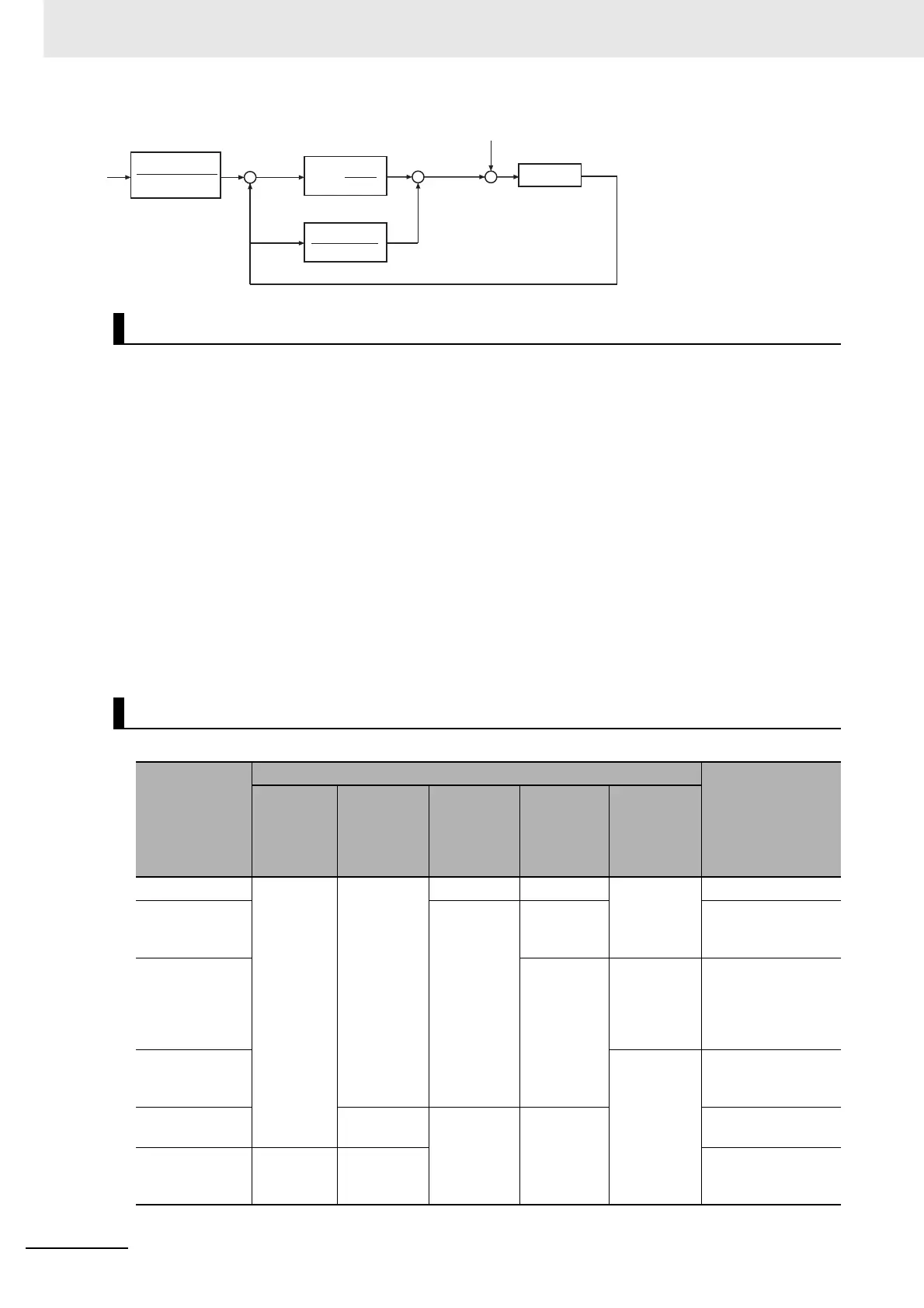

Set

point

Deviation

Manipulated

variable

Process value

Controlled

system

Set point filter

Disturbance

Proportional +

integral components

Advanced derivative

component

+

+

+

+

−

−

Kp: Proportional constant

Ti: Integration time

Td: Derivative time

s: Laplace operator

α: 2-PID parameter

λ: Incomplete derivative coefficient

1 + (1−α)Ti ⋅ s

1 + Ti ⋅ s

Kp ⋅ Td ⋅ s

1 + λ ⋅ Td ⋅ s

Kp +

Kp

Ti ⋅ s

Loading...

Loading...