Maintenance

Version 1.0.4 - 2020-08-0458 Translation of original instruction

MT60

EN

MT60_GB_5.fm

Spindle gear

Vertical milling

Oil level control

The oil level must at least attain the centre resp. top

marking of the oil sight glass.

Start of work,

after every

maintenance or

repair work

Spindle gear

Horizontal milling

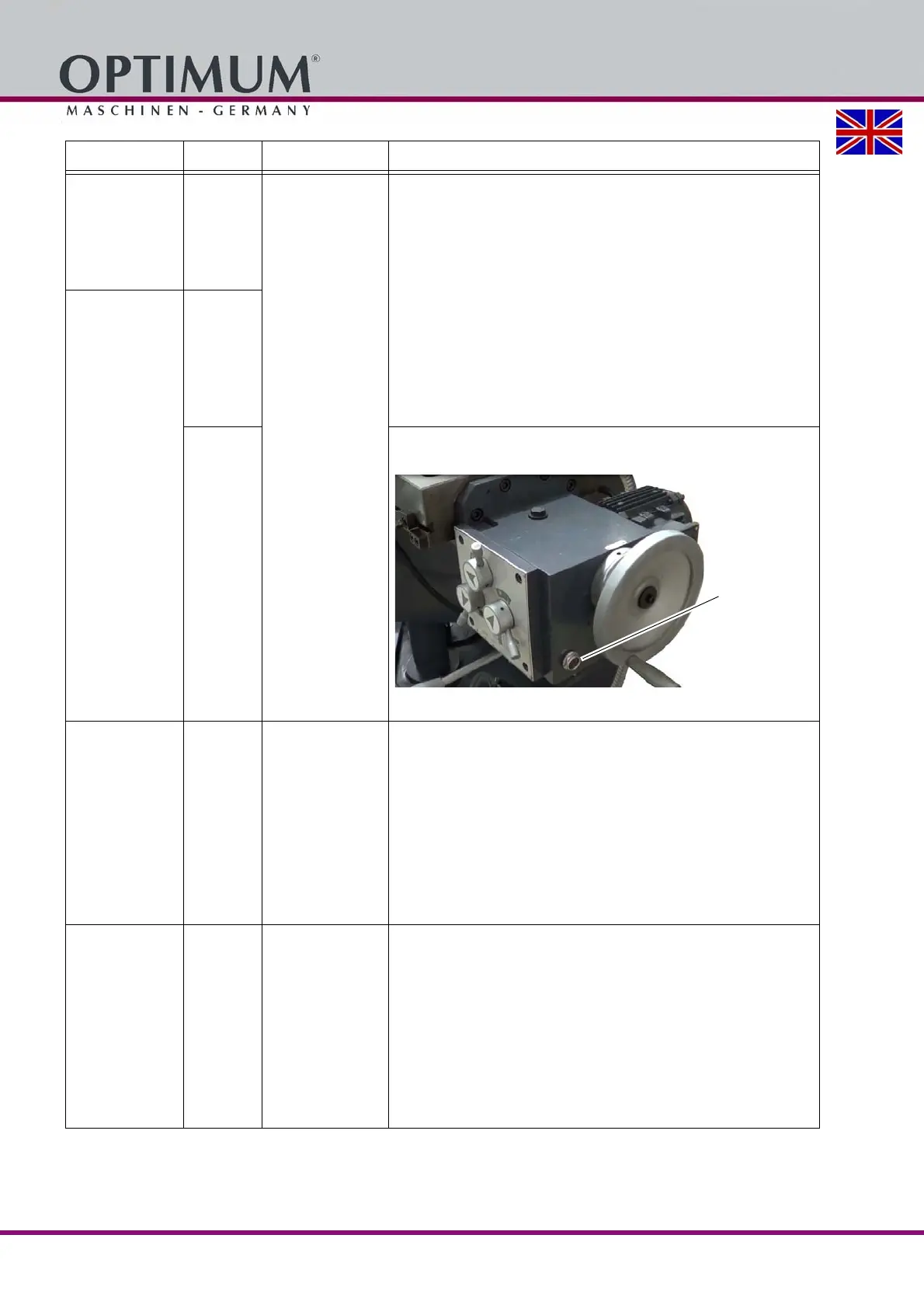

Feed gear

The oil level must at least attain the centre resp. top

marking of the oil sight glass.

Img.6-2: Gear feed oil sight glass

The first time

after 3 month,

then every

6 months

Spindle gear

Vertical milling

Oil change

For oil change use an appropriate collecting tray of suffi-

cient capacity.

Have the milling spindle run for a few minutes, the oil

will heat up and will slightly penetrate from the opening.

Unscrew the screw from the drain hole.

Unscrew the screw from the filler hole.

Close the drain hole if no more oil drains.

Fill up to the middle of the reference mark of the oil sight

glass into the filler hole using a suitable container.

The first time

after 3 month,

then every

6 months

Spindle gear

Horizontal milling

Oil change

For oil change use an appropriate collecting tray of suffi-

cient capacity.

Have the milling spindle run for a few minutes, the oil

will heat up and will slightly penetrate from the opening.

Unscrew the screw from the drain hole.

Unscrew the screw from the filler hole.

Close the drain hole if no more oil drains.

Fill up to the middle of the reference mark of the oil sight

glass into the filler hole using a suitable container.

Interval Where? What? How?

Loading...

Loading...