NOTE: Good practice is to change the bearings before reaching the maximum degree of wear.

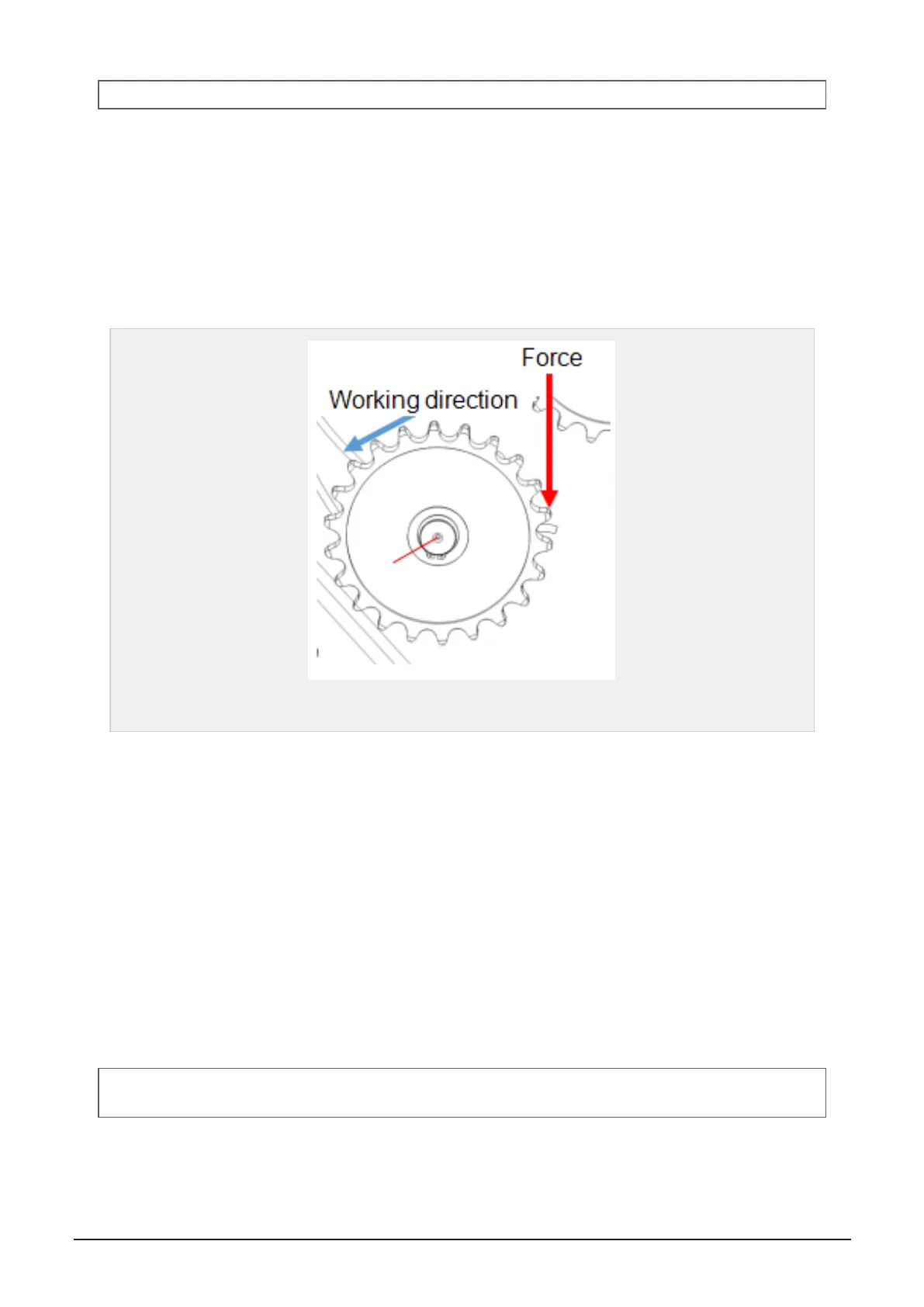

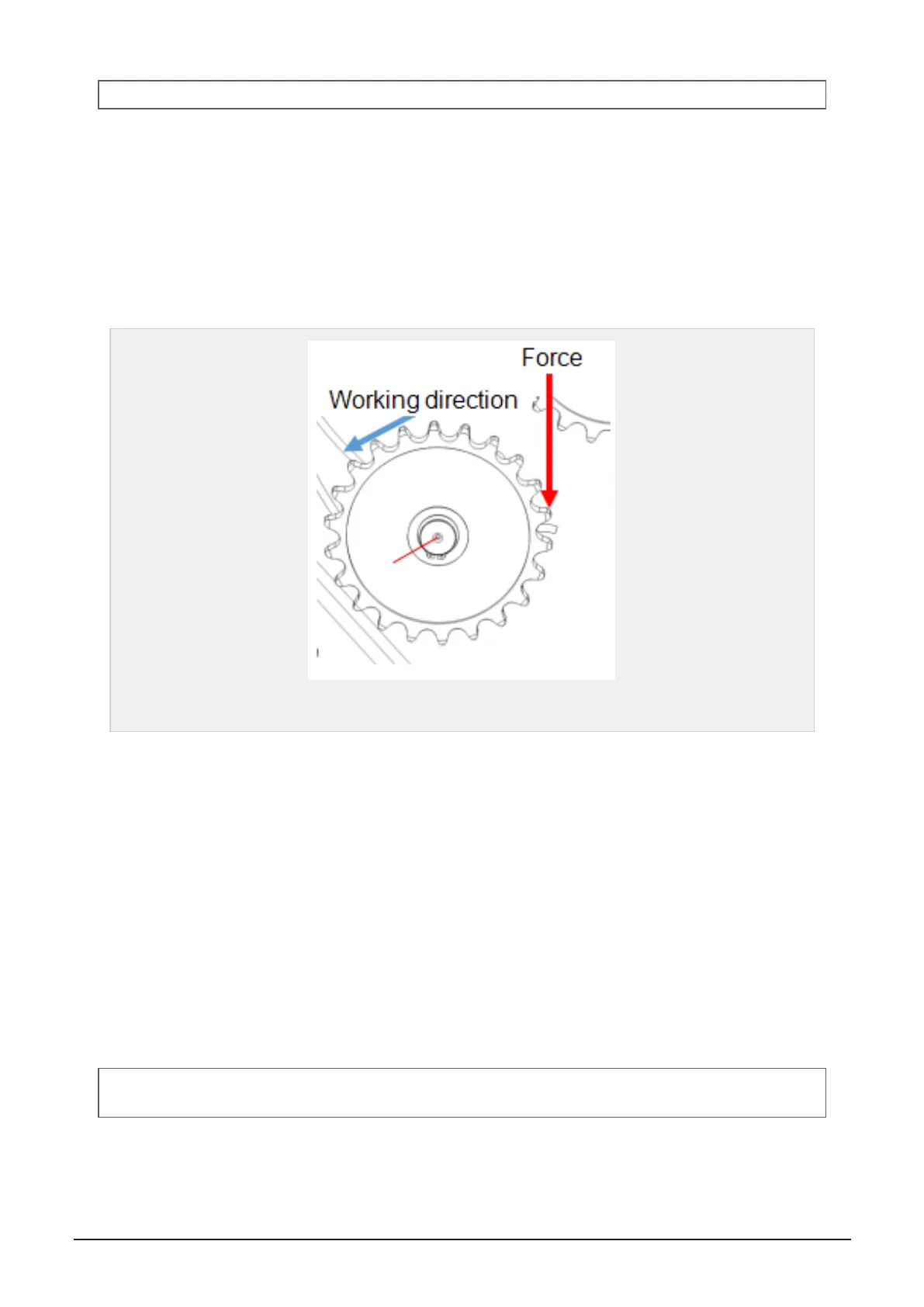

7.11.3 Remove sprockets

The sprockets are fastened to the axle with an eccentric connection. Follow this procedure to loosen the

sprockets.

1. Make an indication mark across both the sprocket and axle (red line) that indicates movement

between the axle and the sprocket.

2. Set a solid steel bar on one of the sprocket teeth, and hit it with a hammer (opposite of the sprocket

working direction).

3. Remove the sprocket, when the indication mark has shifted.

Figure 7.28 :

Sprocket removal

7.12 HYDRAULICS

7.12.1 Hydraulics oil

The oil level is monitored by the control unit. An alarm stating “oil level - low” is displayed in the control unit.

Top up if necessary. The oil level can also be visually checked through an oil glass placed in/on the oil tank.

Check the oil-condition: Minimum once a year.

Change oil: Minimum every third year. See specifications in section 8.6.1 "Hydraulics"

Oil-filter: 3 pcs, must be changed minimum once a year and after the first 50 hours of operation (break-in

period).

7.12.2 Hoses and connections

Check the hydraulic system for any leakages, and that no hoses are rubbing against sharp edges on the

machine.

NOTE: The hydraulic hoses have a limited life time. We recommend to change the hydraulic hoses every six

years.

7 MAINTENANCE AND MECHANICAL ADJUSTMENTS 71

Loading...

Loading...