98

Replacement of Components and Modules

Installation procedure:

→ Carefully insert the entire electronics module into the recess in the lower housing part.

→ Plug the electronics module carefully onto the contact pins for the position measuring system.

→ Refasten the electronics module with the Torx T10 screw (torque 0.4 Nm).

→ Reattach the electrical connections.

→ Check DIP switch positions (4-switch block for color coding, 8-switch block on DeviceNet electronics module

for address and Baud rate) and set the previously noted switch settings, if necessary.

→ If necessary, set AS interface address and jumper positions.

→ If required, make settings again, read out by PC software, using PC software.

→ Perform Teach-In procedure (see Chapter "16.1. Setting the position measuring system (Teach-In)").

Be sure to work carefully and cautiously, so that the electronics are not damaged.

→ Close the housing following the instructions in Chapter "8. Opening and Closing the Housing".

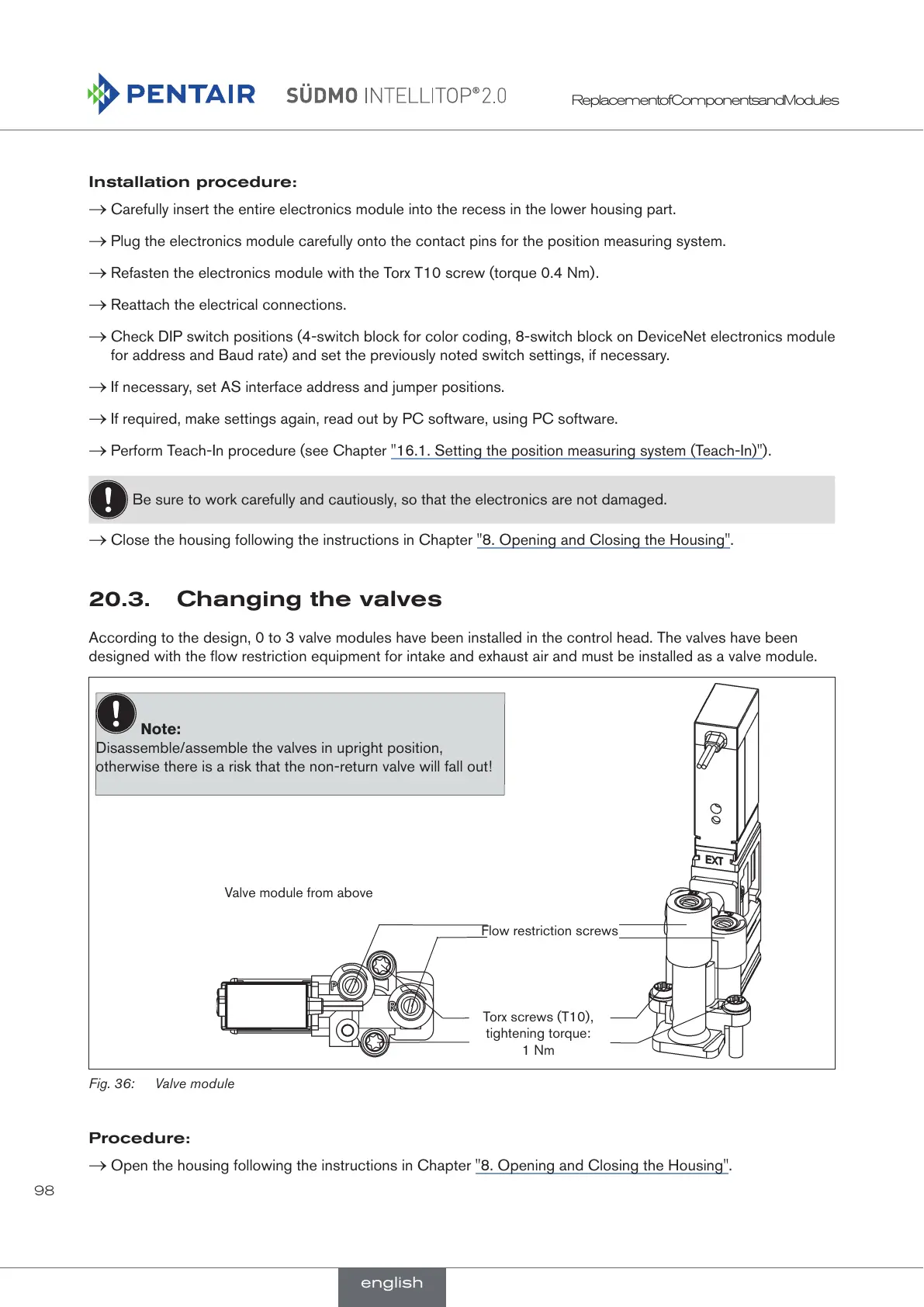

20.3. Changing the valves

According to the design, 0 to 3 valve modules have been installed in the control head. The valves have been

designed with the flow restriction equipment for intake and exhaust air and must be installed as a valve module.

Valve module from above

Flow restriction screws

Torx screws (T10),

tightening torque:

1 Nm

Note:

Disassemble/assemble the valves in upright position,

otherwise there is a risk that the non-return valve will fall out!

Fig. 36: Valve module

Procedure:

→ Open the housing following the instructions in Chapter "8. Opening and Closing the Housing".

english

Loading...

Loading...