21

DO NOT run the pump dry. If the pump is run dry, the mechanical seal will be damaged and the pump will start leaking. If this

occurs, the damaged seal must be replaced. ALWAYS maintain proper water level. If the water level falls below the suction port,

the pump will draw air through the suction port, losing the prime and causing the pump to run dry, resulting in a damaged

seal. Continued operation in this manner could cause a loss of pressure, resulting in damage to the pump case, impeller and

seal and may cause property damage and personal injury.

Restart Instructions

If

SuperFlo

®

VS Variable Speed

Pump is installed

below the water level of the pool, close return and

suction lines prior to opening hair and lint pot on

pump. Make sure to re-open valves prior to operating.

Priming the Pump

The pump strainer pot must be lled with water before

the pump is initially started.

Follow these steps to prime the pump:

1. Remove the pump lid plastic clamp. Remove the

pump lid.

2. Fill the pump strainer pot with water.

3. Reassemble the pump cover and plastic clamp onto

the strainer pot. The pump is now ready to prime.

4. Open the air release valve on the lter, and stand

clear of the lter.

5. Turn on the switch or time clock.

6. When water comes out of the air release valve,

close the valve. The system should now be free of

air and recirculating water to and from the pool.

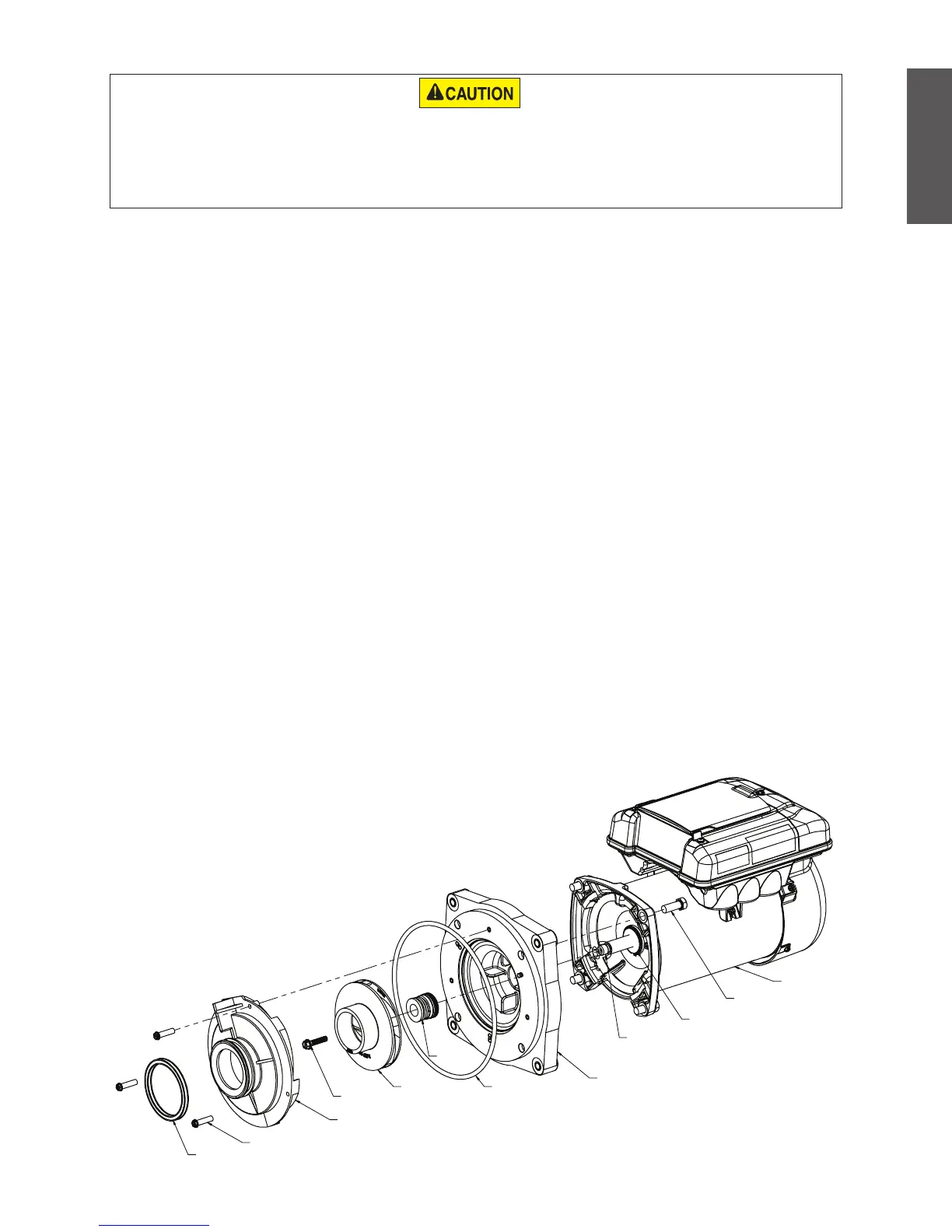

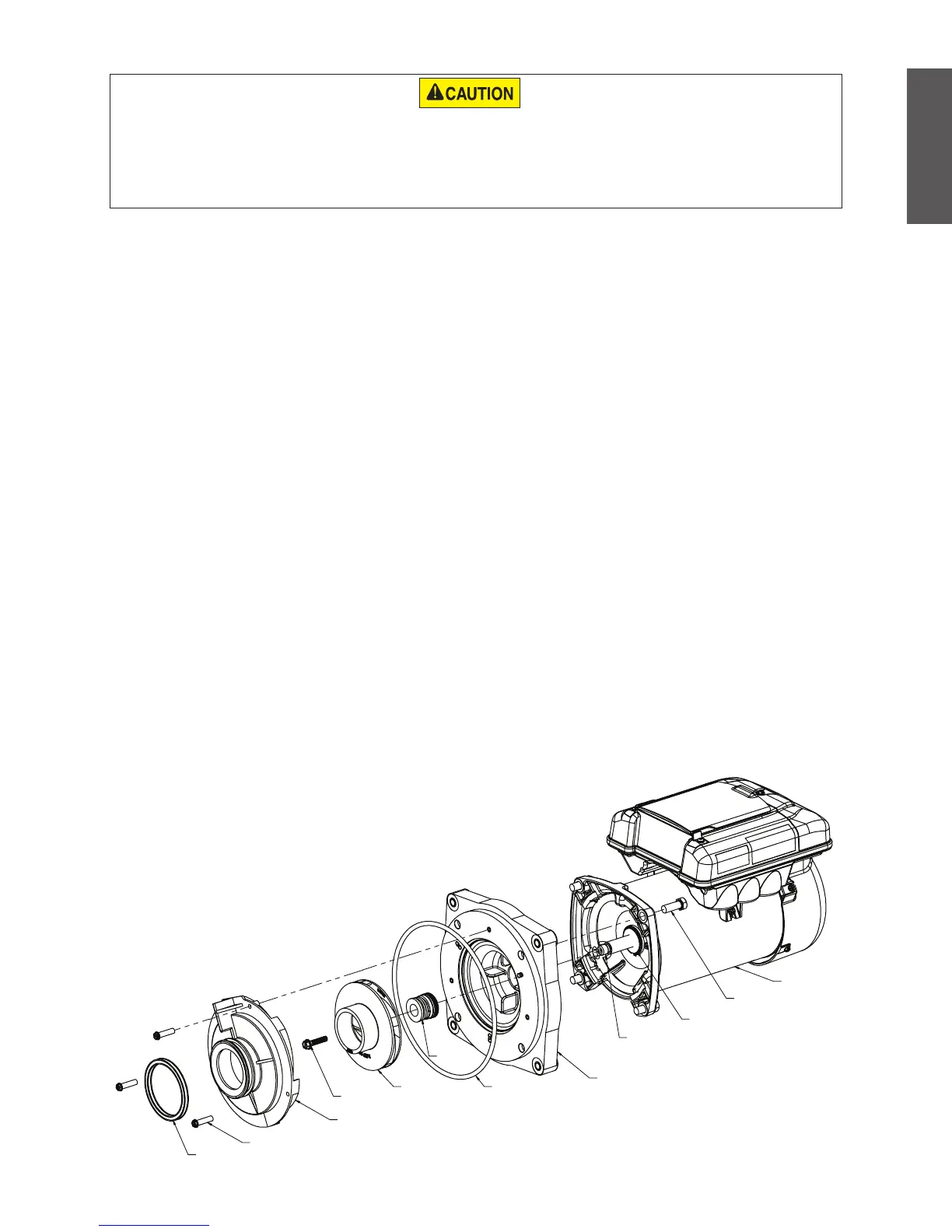

Pump Reassembly

1. When installing the replacement seal into the seal

plate, use soapy water to wet the rubber boot

before pressing it into the seal plate.

2. Remount the seal plate to the motor.

3. Before installing the rotating portion of the seal on

the motor shaft, wet the motor shaft with soapy

water and slide the seal onto the motor shaft.

Ensure that the carbon face contacts the ceramic

face of the stationary seat. Press the seal into

the seal plate with your thumbs and wipe o the

ceramic with a clean cloth.

4. Grease the motor shaft thread and screw impeller

onto the motor shaft.

5. Screw in the impeller lock screw (counter-clockwise

to tighten).

6. Remount the diuser onto the seal plate. Make

sure the plastic pins and holding screw inserts are

aligned.

7. Grease the diuser quad ring and seal plate O-ring

prior to reassembly.

8. Grease the bolt threads, assemble the motor sub-

assembly to the strainer pot-pump body by using

the two through bolts for proper alignment. Do not

tighten the through bolts until all 4 bolts are in place

and nger tightened.

9. Fill the pump with water.

10. Reinstall the pump lid and plastic clamp; see the

next section, ‘Restart Instructions’.

11. Re-prime the system.

SEAL PLATE O-RING

QUAD RING

DIFFUSER SCREW

DIFFUSER

IMPELLER SCREW

IMPELLER

SEAL PLATE

BOLT

MOTOR

MOTOR SHAFT

MOTOR SLINGER

SHAFT SEAL

Motor Assembly

English

Loading...

Loading...