Adjustment

13 - 22

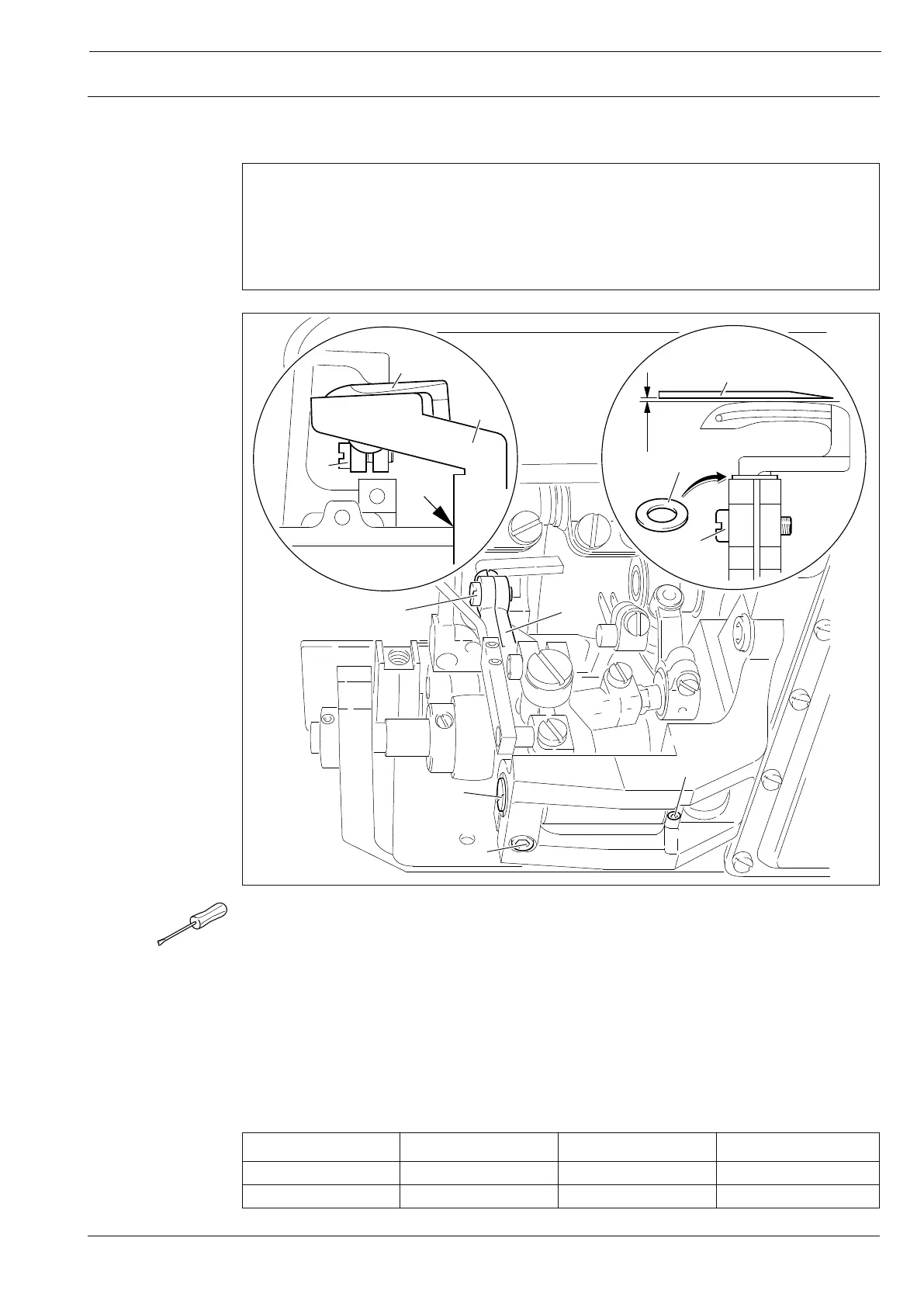

Fig. 13 - 19

0,3 mm

7

5

7

1

3

2

4

7

8

9

6

13.05.19 Looper height and looper angle (for the 3801-3/071 and -11/071)

Requirements

When the looper carrier 1 is vertical

1. there must be a clearance of 0.3 mm between the highest point of the back of the

looper and the bottom of the thread trapper 9, and

2. looper 6 must touch looper adjustment gauge 8.

● Position looper carrier 1 so that it is vertical.

● Disassemble needle plate and bottom feed dog.

● Turn eccentric bearing pin 2 (screws 3 and 4) according to requirement 1.

● Check adjustment.

● If the required clearance is not achieved, replace the spacer 5. To do this, looper 6

(screw 7) must be dismounted.

● Lay looper adjustment gauge 8 (Part No. 61-111 643-06) on the left edge of the cover plate

groove (see arrow) and slide against looper 6.

● Position looper 6 (screw 7) so that it touches looper adjustment gauge 8 (requirement 2).

Spacer Part No. Spacer Part No.

0,3 mm 91-170 693-05 0,8 mm 91-169 615-05

0,5 mm 91-169 614-05 1,2 mm 91-170 694-05

Loading...

Loading...