Adjustment

13 - 24

6

4

5

3,6

54-065

1

2

3

3,6 mm

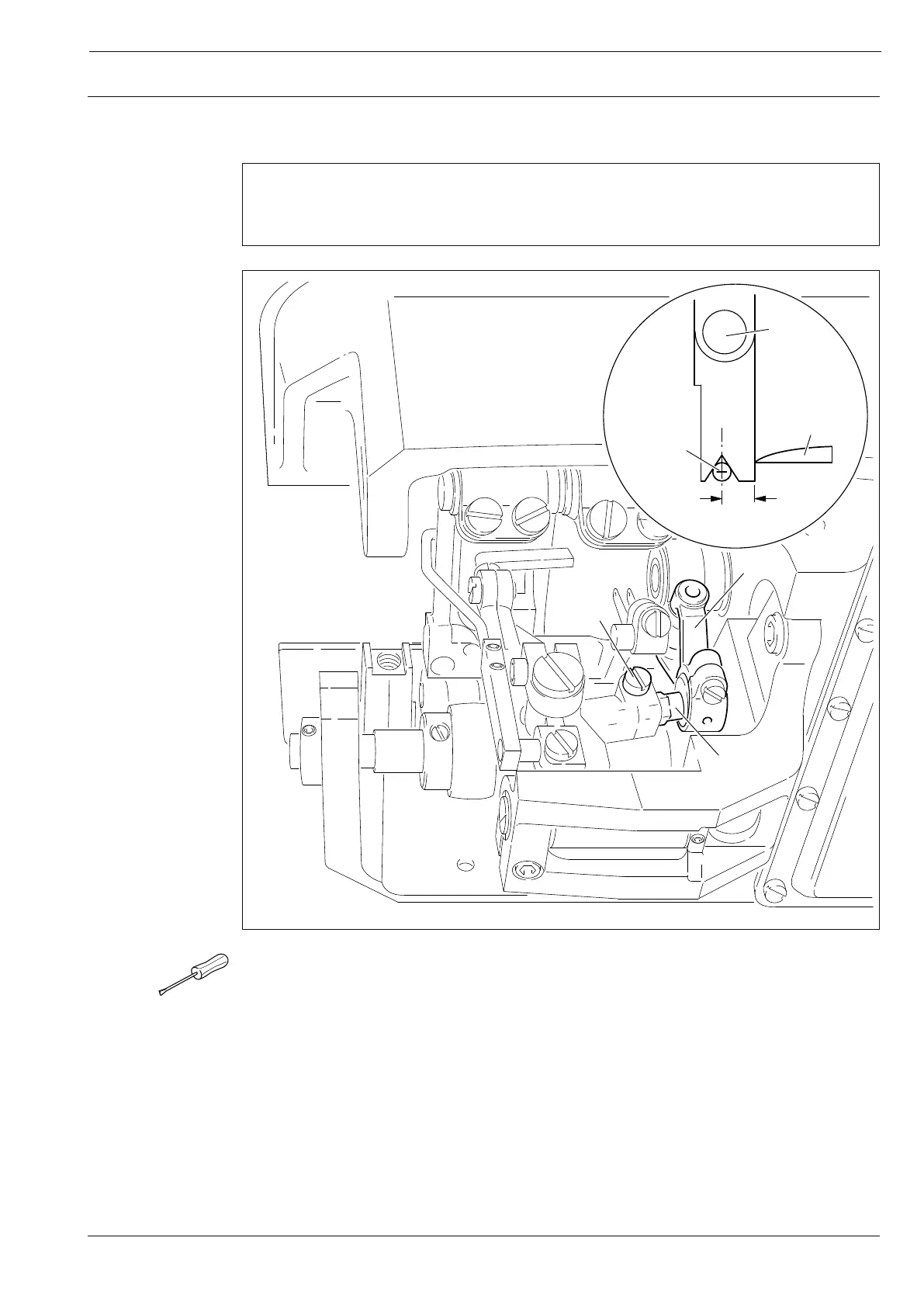

Fig. 13 - 21

13.05.21 Looper-to-needle clearance (crosswise to sewing direction)

Requirement

When the looper 1 is at its right point of reversal, there must be a clearance between the

looper point crosswise to the sewing direction and the needle center of 3.6 mm.

● By turning the balance wheel bring the looper 1 to its right point of reversal.

● Place the "3.6" blade of looper gauge 2 (Order No. 61-111 643-06) against the needle 3 with

its notch facing the direction of feed.

● Make sure that the driving link 4 is vertical and turn the ball pin 5 (screw 6) with the aid of

an open-ended spanner, until the looper point 1 contacts the blade.

Loading...

Loading...