Car and Maintenance

78

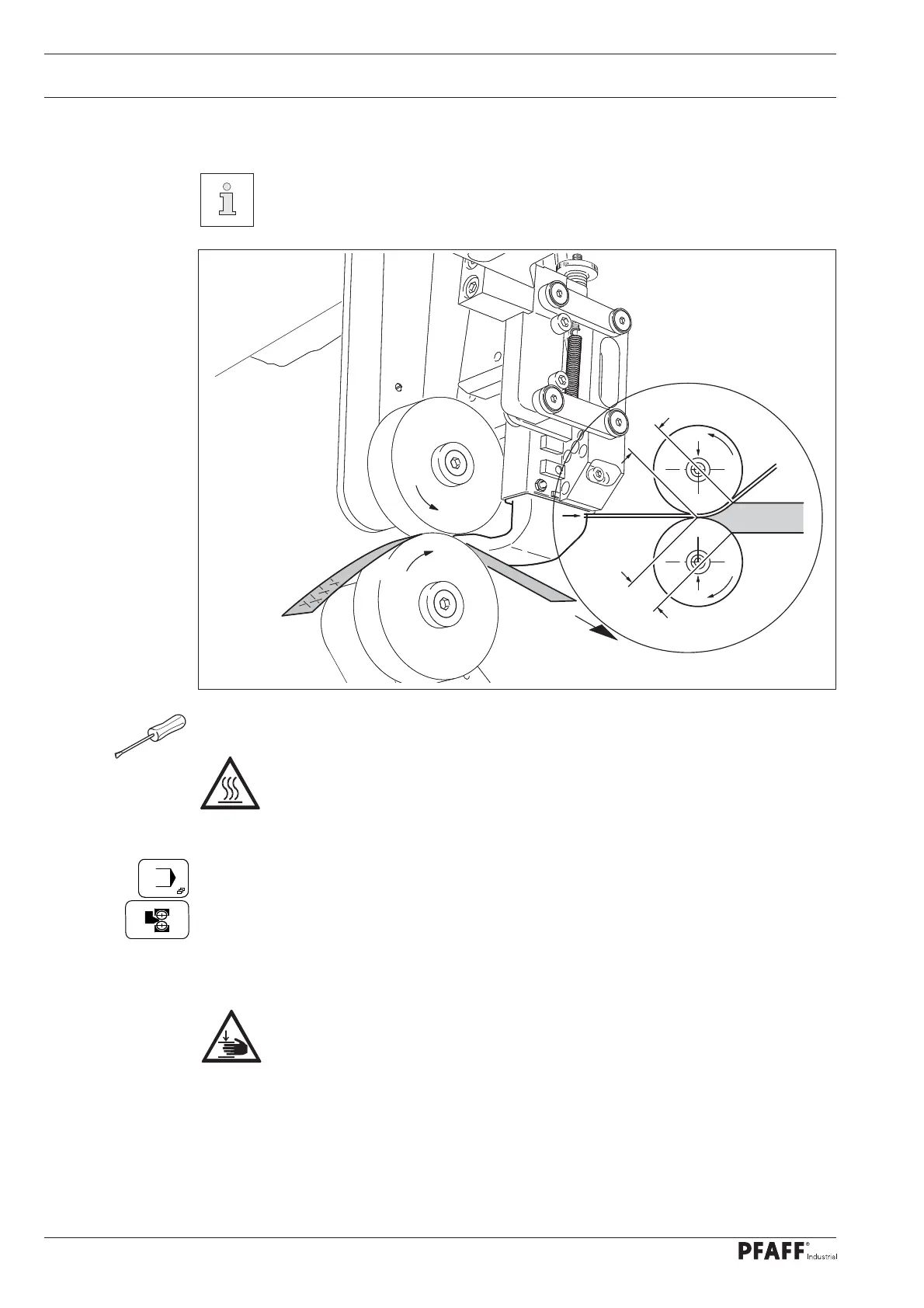

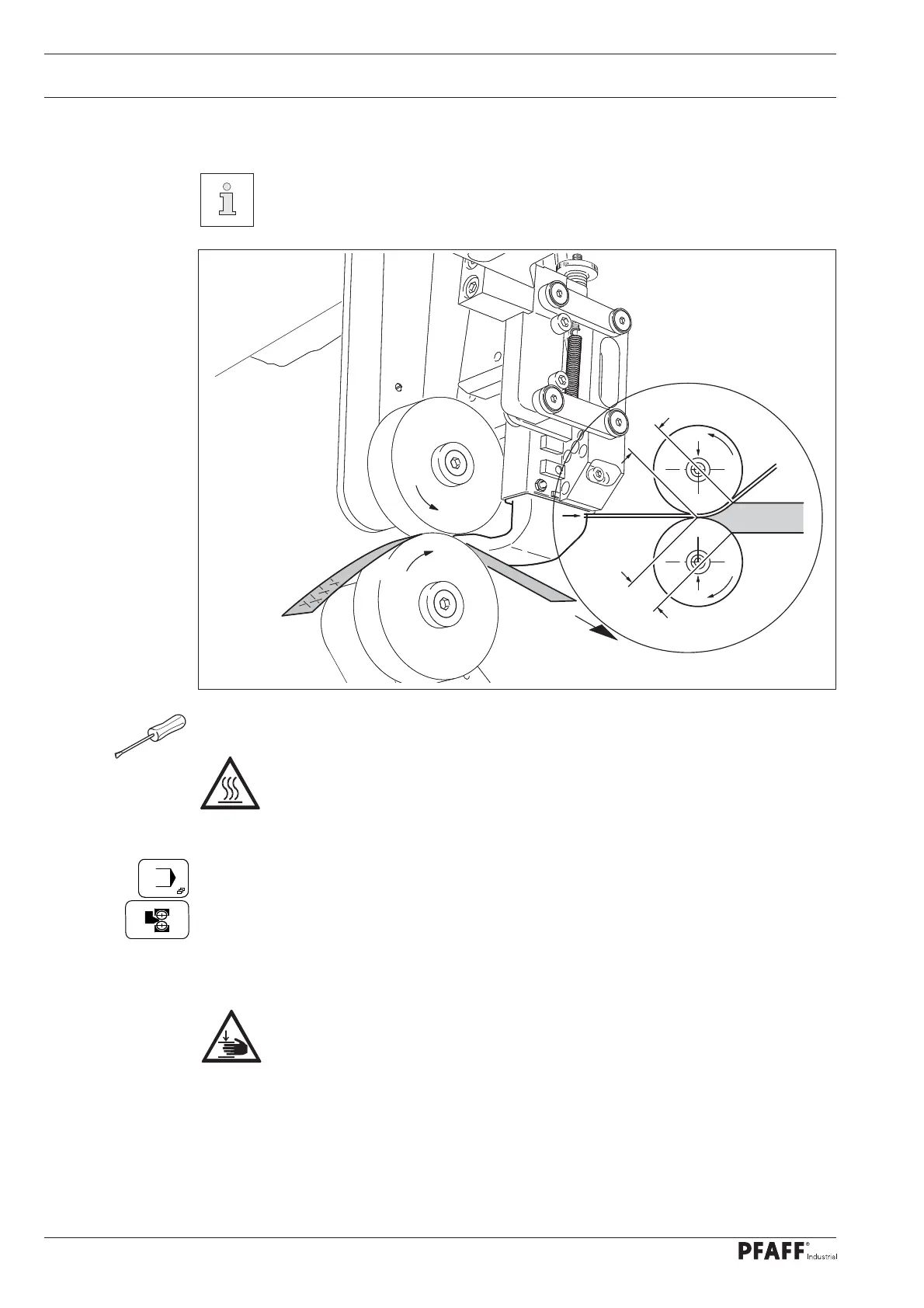

12.05 Grinding the hot wedge (only on the PFAFF 8390-010)

It is only necessary to grind the hot wedge if it is deformed due to wear or

corrosion (when processing PVC in a single shift operation, about once a week)

or when a new hot wedge has been installed.

● Switch on the machine and set the sealing temperature at its minimum value.

Let the hot wedge cool down!

Danger of burns if the hot wedge is touched!

● Fit the smooth feed rollers, see Chapter 13.03 Changing the feed rollers.

● Call up the input menu.

● Call up the Grinding the hot wedge function and, if necessary, adjust the feed speed.

● Place sandpaper (grain size 100) between the feed rollers and lower the top feed roller

with the pedal function.

Do not place fi ngers between the feed rollers!

Danger of crushing if the fi ngers are caught between the running feed rollers!

● Engage the hot wedge with the pedal function and start the feed rollers.

● Guide the sandpaper by hand and work both sides of the hot wedge until its shape fi ts

the feed rollers and the measurement "x" is the same size at the top and bottom.

● Check the setting of the hot wedge and correct it if necessary, see Chapter 13.06 Adju-

sting the hot wedge.

Fig. 12 - 03

x

x

Loading...

Loading...