Adjustment

88

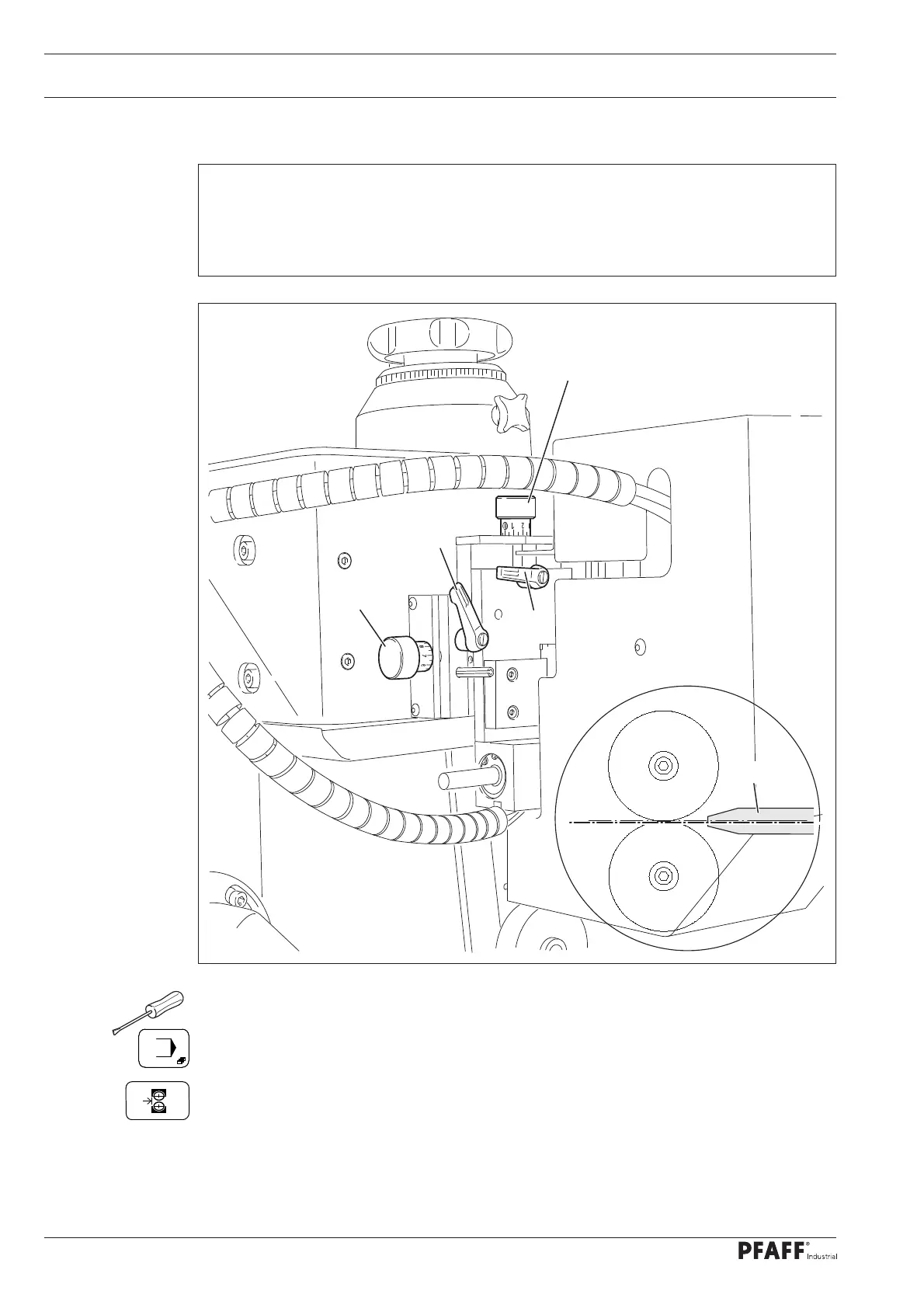

Fig. 13 - 09

3

4

1

2

5

13.08.02 Adjusting the height and feed roller clearance of the hot air nozzle

● Switch on the machine and set the sealing temperature to its minimum value.

● Call up the input menu.

● Position the heating element.

● Adjust screw 1 (clamp screw 2) in accordance with requirement 1.

● Adjust screw 3 (clamp screw 4) in accordance with requirement 2.

● Switch off the machine.

Requirement

1. The height adjustment of not air nozzle 5 depends on the material, and the standard

setting is centred to the feed rollers.

2. There should be clearance of ca. 1 -2 mm between hot air nozzle 5 and the workpiece.

Loading...

Loading...