Adjustment

86

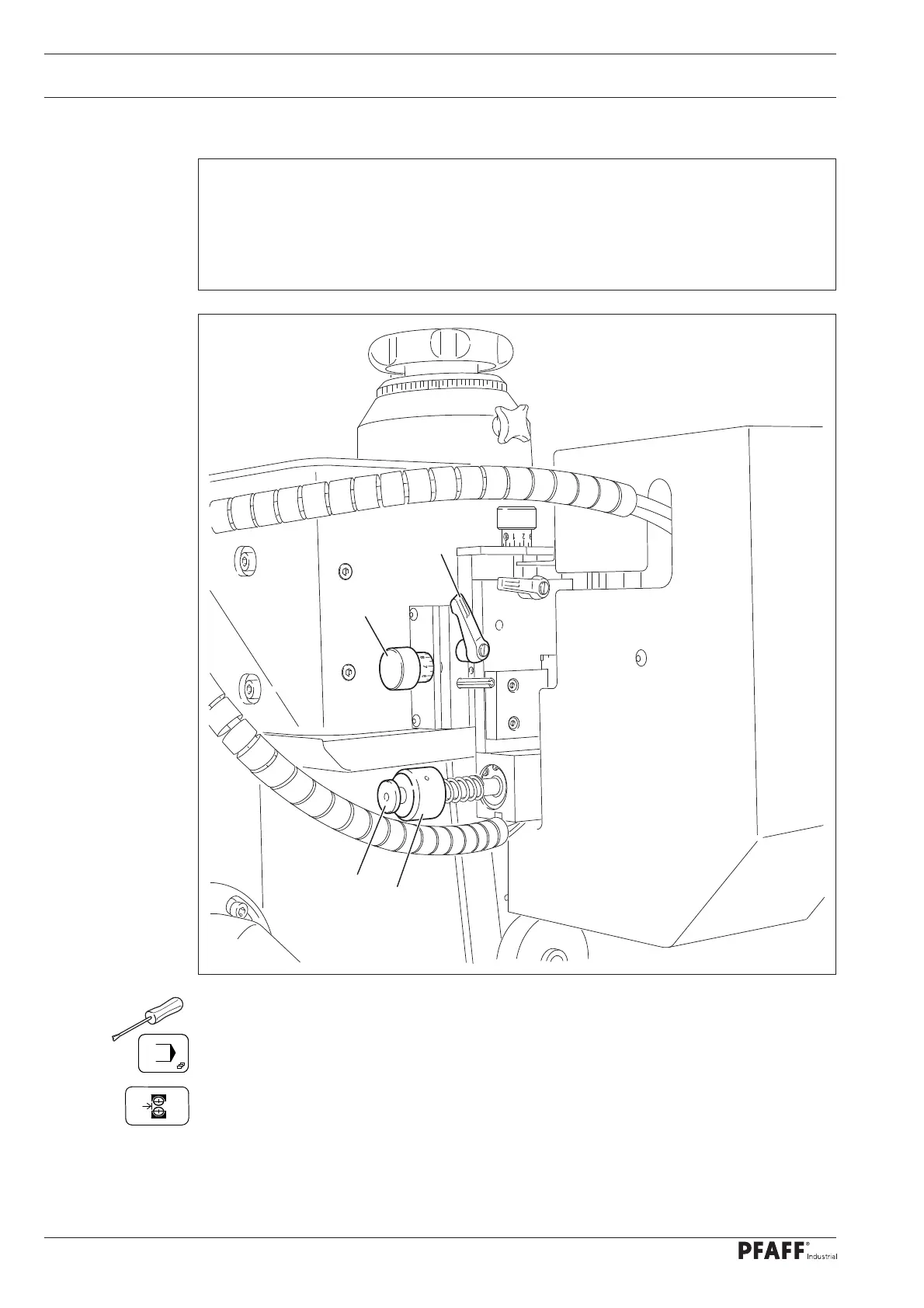

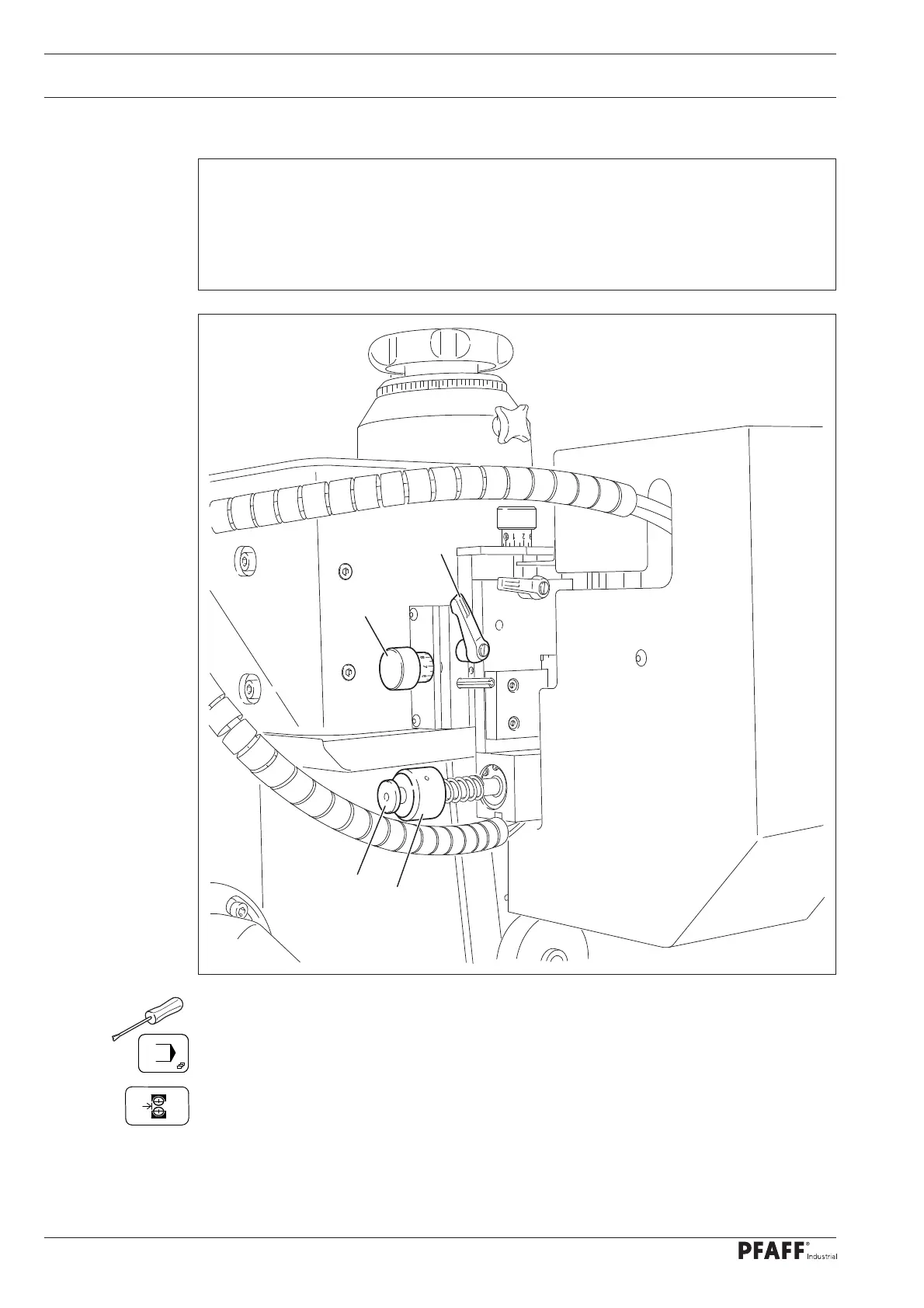

1

2

3

4

Fig. 13 - 07

● Switch on the machine and set the sealing temperature at its minimum value.

● Call up the input menu.

● Position the heating element

● Adjust screw 1 (clamp screw 2) in accordance with requirement 1.

● Adjust screw 3 (lock screw 4) in accordance with requirement 2.

● Switch off the machine.

13.07.03 Hot wedge to feed roller clearance and contact pressure

Requirement

1. The hot wedge should be touching the workpiece.

2. The contact pressure of the hot wedge should be set so that a good seam quality

is

guaranteed, and so that the hot wedge cannot move backwards when sealing cross

seams.

Loading...

Loading...