Product description

14

4.2 Interface connection

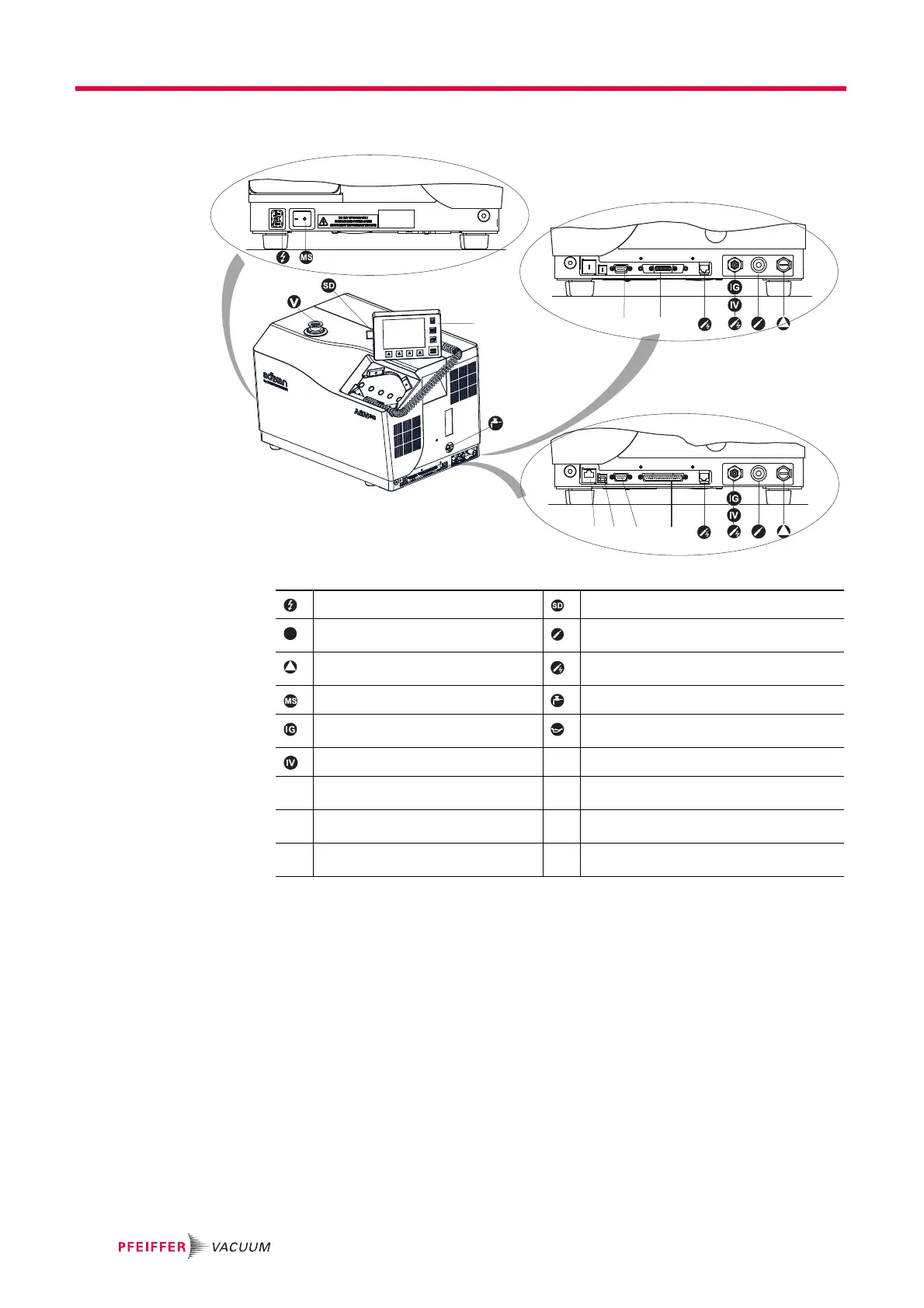

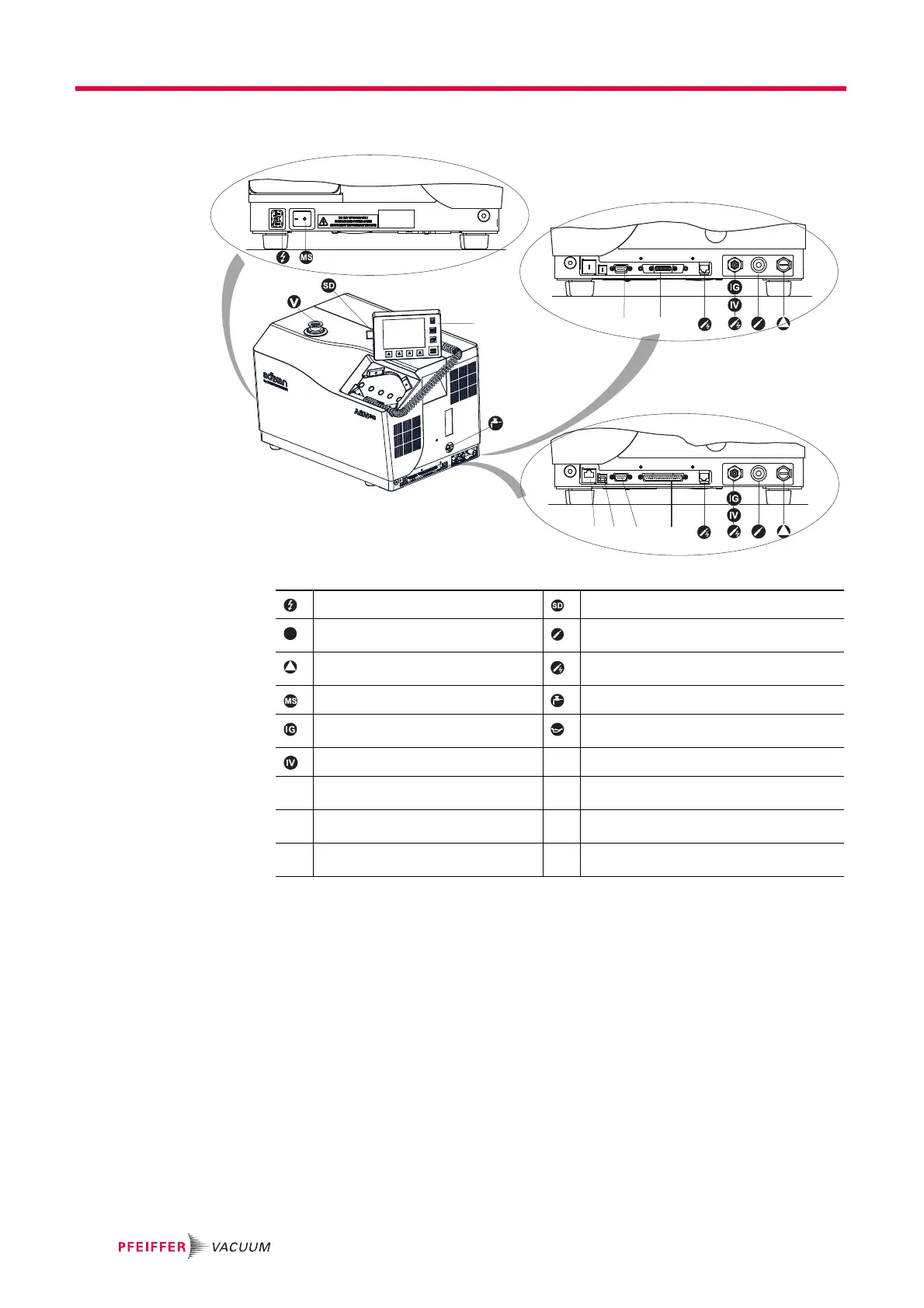

Fig. 2: Human-machine interface

1) Accessory or option (at the customer's expense)

2) Accessory (at the customer's expense)

4.3 Test method

The test method is chosen depending on the part to be tested.

For more information about leak detection test methods, see Leak detector compendi-

um on the website www.pfeiffer-vacuum.com.

4.3.1 Hard vacuum test

● Part that can be connected to pipe and placed under a vacuum

● Part that can be placed in a vacuum chamber

Spray method This method involves removing the air from the part to be tested, connecting it to the de-

tector's analyzer cell, then spraying tracer gas on the points of the part that are likely to

leak. The detector measures the flow of tracer gas that penetrates due to part leakage.

Mains power supply SD card

Detector inlet (Inlet port) Standard sniffer probe connection

2)

(STANDARD SNIFFER)

Primary pump Exhaust (EXHAUST) Smart sniffer probe connection

2)

(SMART SNIFFER)

Switch/Circuit breaker Oil draining (Wet model)

Neutral gas inlet (purge)

(SMART SNIFFER/VENT/PURGE)

Filling with oil (Wet model)

Air inlet

1 Standard remote control connector

2)

4 Interface Connector- I/O D-Sub 37 pins

(INPUTS/OUTPUTS)

1)

2 RS 232 connector D-Sub 9 pins

(SERIAL)

5 USB plug (USB)

3 Interface Connector- I/O D-Sub 15 pins

(INPUTS/OUTPUTS)

1)

6 Ethernet plug

1)

or Wi-Fi Antenna

1)

(NETWORK)

Loading...

Loading...