Installation

18

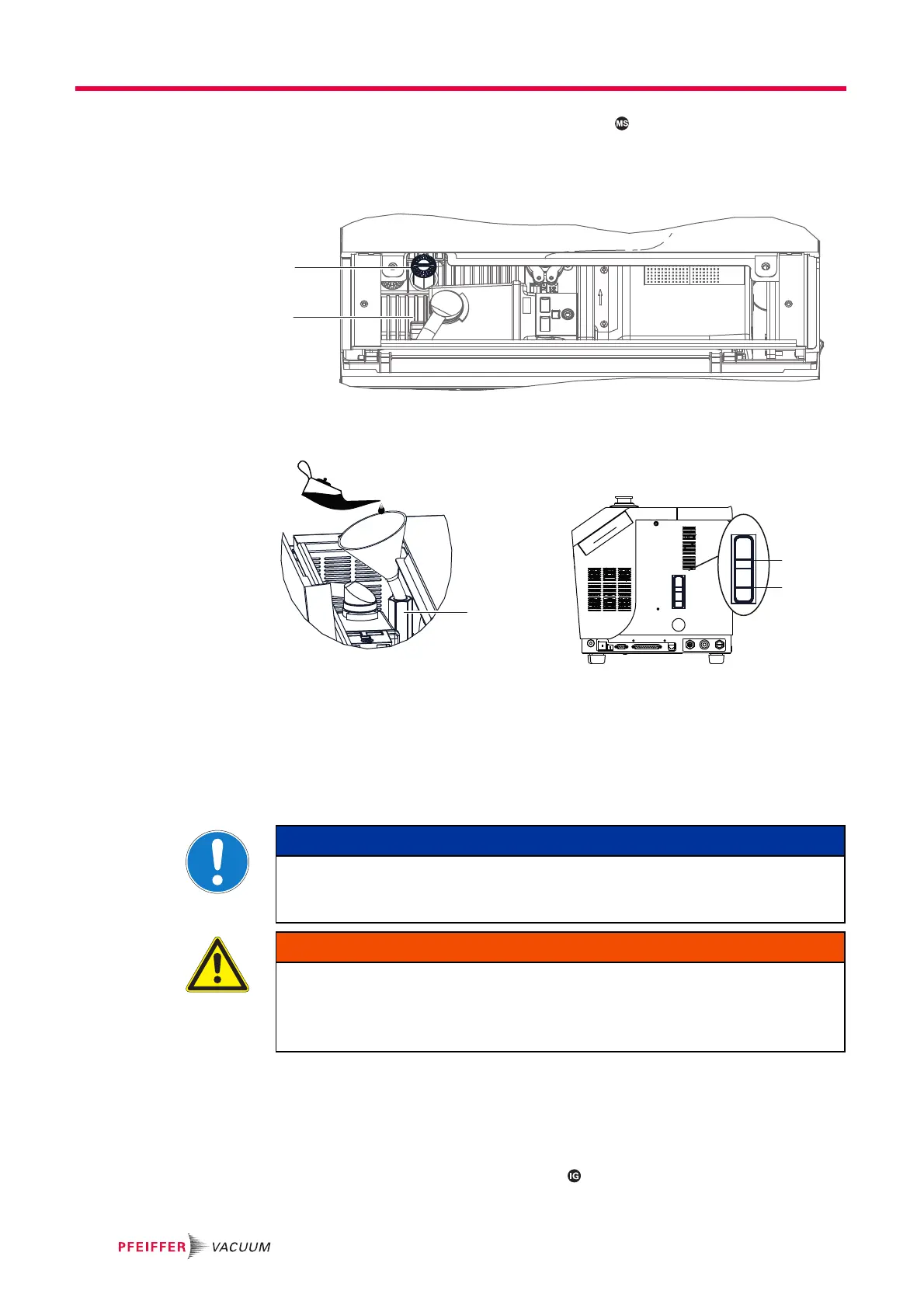

Make sure that the detector is off (circuit breaker at 0, the control panel screen is

off) and in a horizontal position.

Open the cover.

Remove the oil fill cap (1) from the rotary vane pump (2).

Put the funnel (included with the detector) in the oil fill opening (3).

Fill with oil to the highest level.

Replace the oil fill cap tightly (1).

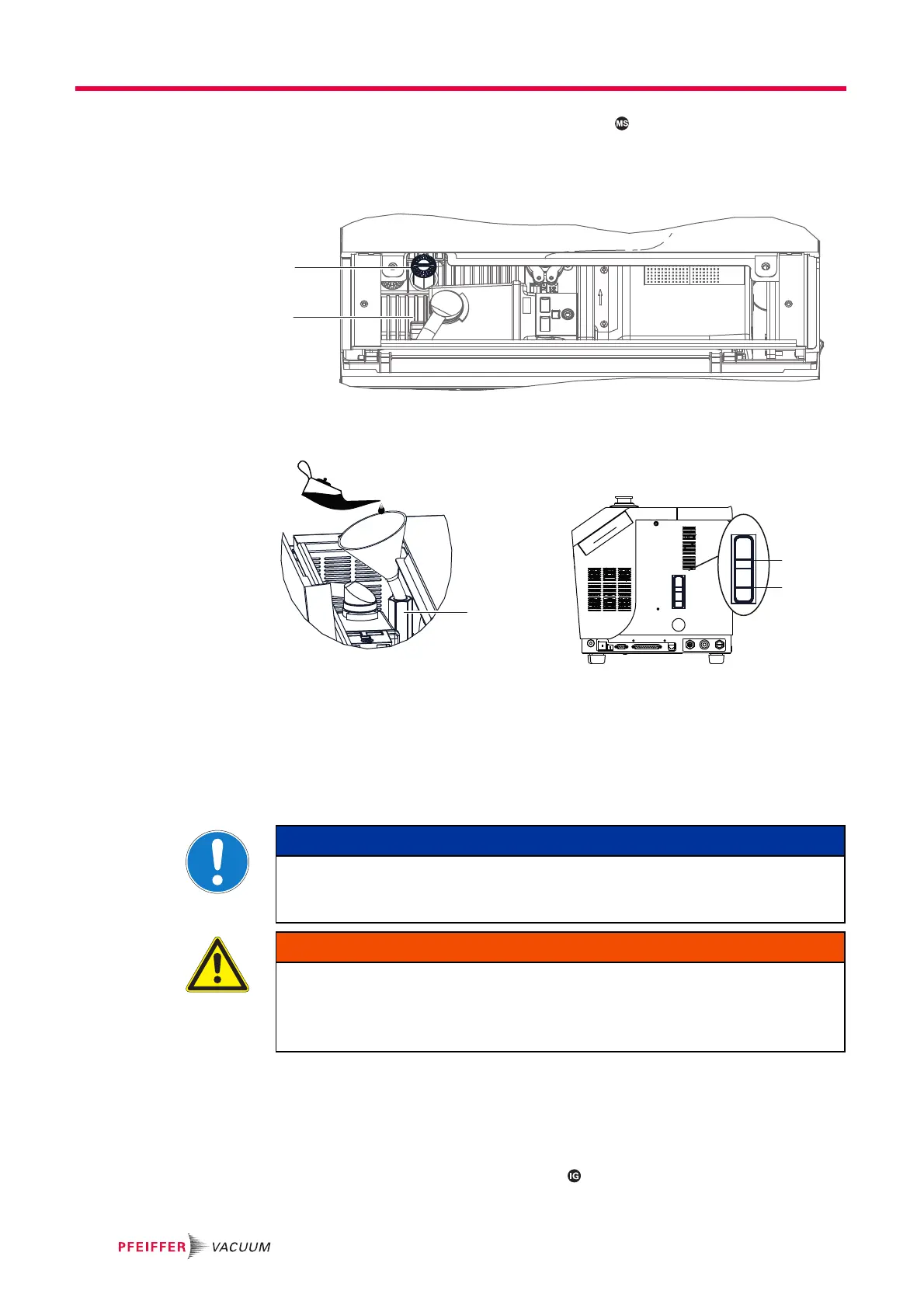

5.5 Connecting the purge circuit

The Dry Model's purge system can be connected to a purge circuit and can be open/

closed depending on the settings.

The Wet Model's purge system is always closed and cannot be set by the operator.

To guarantee best performance, the nitrogen supply must be clean and filtered, with the

following characteristics:

– relative excess pressure : 200 hPa

– flow rate: 50 sccm

Attach the nitrogen pipe to the connector (see 4.2).

Regulate the purge flow rate.

Max

Min

3

NOTICE

Tracer gas concentration

When the air purge is used, we recommend performing the leak detection in a ventilated

room.

WARNING

Pressurised circuit

To work safely on the product, the operator must:

Install a manual valve on the nitrogen circuit at a distance of 3 m from the product, so

that the nitrogen supply can be locked.

Loading...

Loading...