PIPER AIRCRAFT, INC.

PA-28-161, WARRIOR III

MAINTENANCE MANUAL

PAGE 15

Nov 30/06

5C21

74-10-00

(d) Insert T-150 "E" Gap Gauge between the pole laminations in the rotor shaft and the pole

laminations in the frame. Read the magneto data plate for magneto rotation.

1 For old style rotor (i.e. - no slots on the magnet head), insert flat end of T-150 "E"

Gap Gauge. Insert the "E" Gap Gauge against the right lamination for right-hand

rotation magnetos and against the left laminations for left-hand rotation magneto.

2 For new style rotors (with slots on magnet head), insert notched end of T-150 "E"

Gap Gauge. Locate the appropriate "L" or "R" timing slot on the rotor magnet head

and insert the notched end of the "E" gap gauge. Use the "L" slot for left-hand

rotation magnetos and the "R" slot for right-hand rotation magnetos.

(e) Rotate the magneto frame on the T-125 assembly fixture until the T-150 "E" Gap Gauge

rests against the pole lamination in the magneto frame. Rotate the magneto frame

clockwise for left-hand rotation magnetos and counterclockwise for right-hand rotation

magnetos. The magneto rotor shaft is now in "E" Gap position.

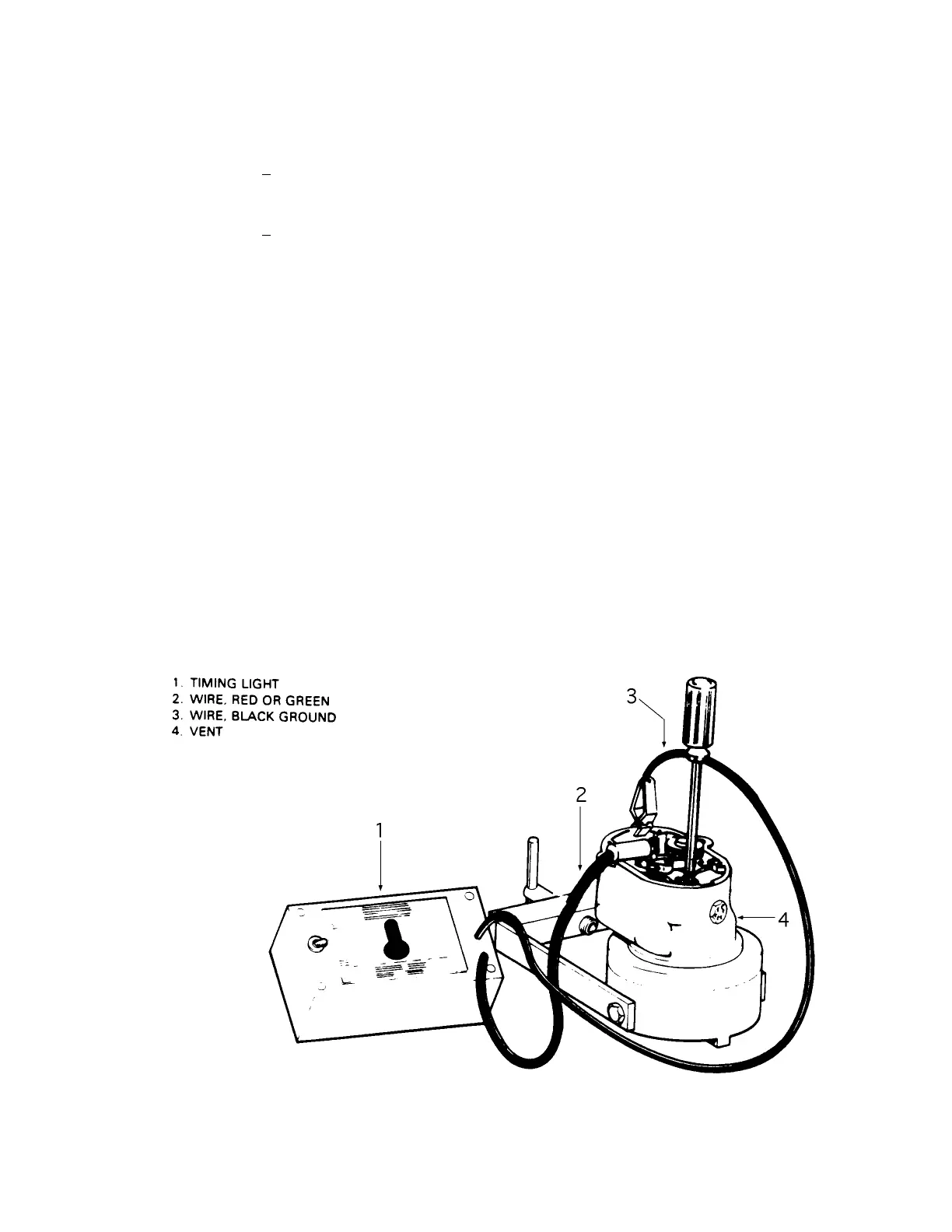

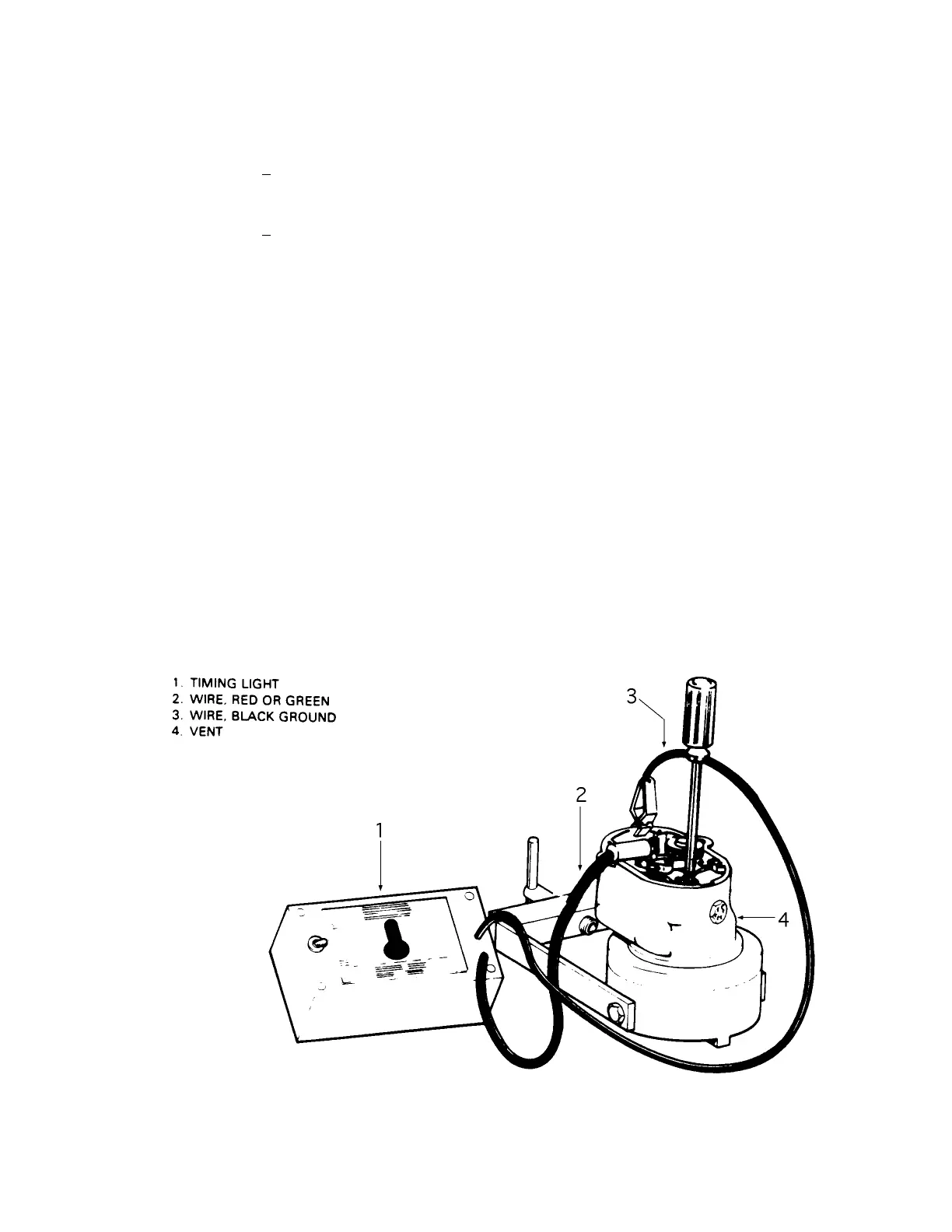

(f) Using a timing light (see Figure 13), adjust the contact points to be just opening when the

frame is against the T-150 gauge. This will provide a point gap opening of .008-.012

inches.

(g) Secure the points in this position by tightening the screws. Torque adjusting screw to

18-20 in.-lbs. Torque the pivot screw to 15-18 in.-lbs.

(h) Apply cam grease sparingly to each lobe of the cam.

(i) Attach coil lead wire to the vertical bronze male terminal of the primary point assembly.

(11) Assemble the condenser into the distributor housing, being sure to rotate the condenser wire

the same rotation as the condenser is tightened in the housing.

Magneto Internal Timing

Figure 13

Loading...

Loading...