PowerFleet

®

VAC4 and VAC4S Hardware User’s Guide

13-Impact Sensor Er (Refer to Hardware Guide)

[FUNCTIONAL] System reports no impact sensor is installed.

• Verify that the impact sensor is properly connected to the VAC (connector C103).

Impact sensor cable

damage

• Verify that the impact sensor cable is not damaged.

• Replace sensor as needed and retest.

Impact sensor is not

getting power from

the VAC

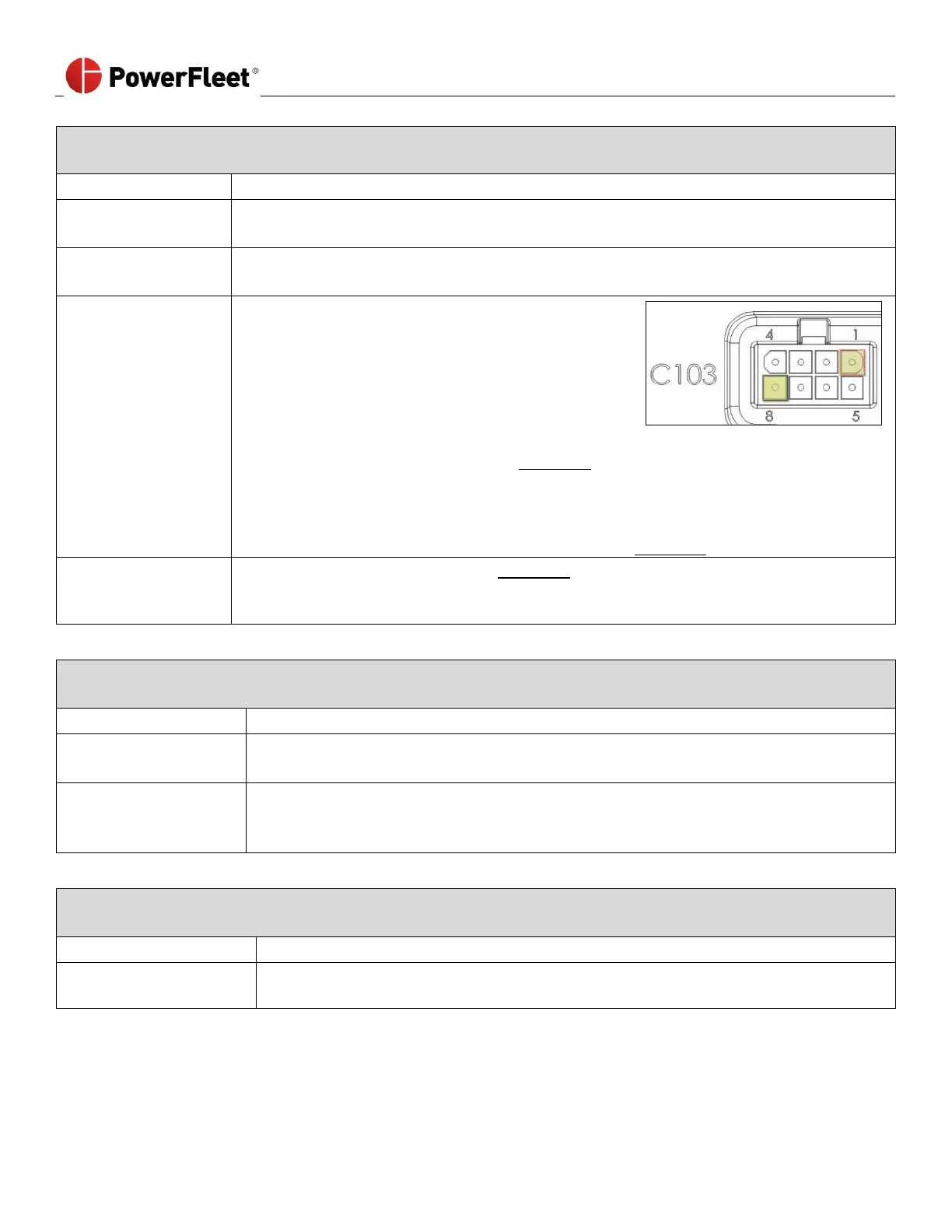

• Verify that the VAC is supplying adequate voltage by

unplugging the impact sensor connector and

connecting a voltmeter to pin 1 (positive) and pin 8

(negative) on C103 of the VAC. The image at right

shows how to read the pin layout and direction.

• You must have 5.5 ± 0.5 volts DC.

• If the VAC is not supplying 5.5 ± 0.5 VDC

o Complete an RMA Request form (See Appendix A)

o Call PowerFleet’s Customer Service for an RMA number.

o Only the VAC should be returned for analysis/repair.

o Once VAC is removed, the system MUST be hard-bypassed to use vehicle.

Follow instructions on how to hard-bypass the system (See Appendix B).

• Complete an RMA Request form (See Appendix A)

• Call PowerFleet’s Customer Service for an RMA number.

• Only the Impact sensor should be returned for analysis/repair.

14-SPI Error Low (Refer to Hardware Guide)

[FUNCTIONAL] The VAC cable is picking up electrical noise causing SPI errors greater than 1% of the time.

• Visually inspect the VAC cable to verify that the VAC cable is not damaged.

• Replace the cable as needed.

• Verify that the VAC cable is routed away from high electrical noise devices such as

traction motors and contactors.

• If chassis noise is present, reroute the cable and retest.

15- Run Configuration Wizard – [SHUTDOWN] The configuration wizard was never run for the VAC that is currently

installed on the vehicle.

• Log in to the VAC as a Maintenance operator and re-run the configuration wizard

(see Section 2)

Loading...

Loading...