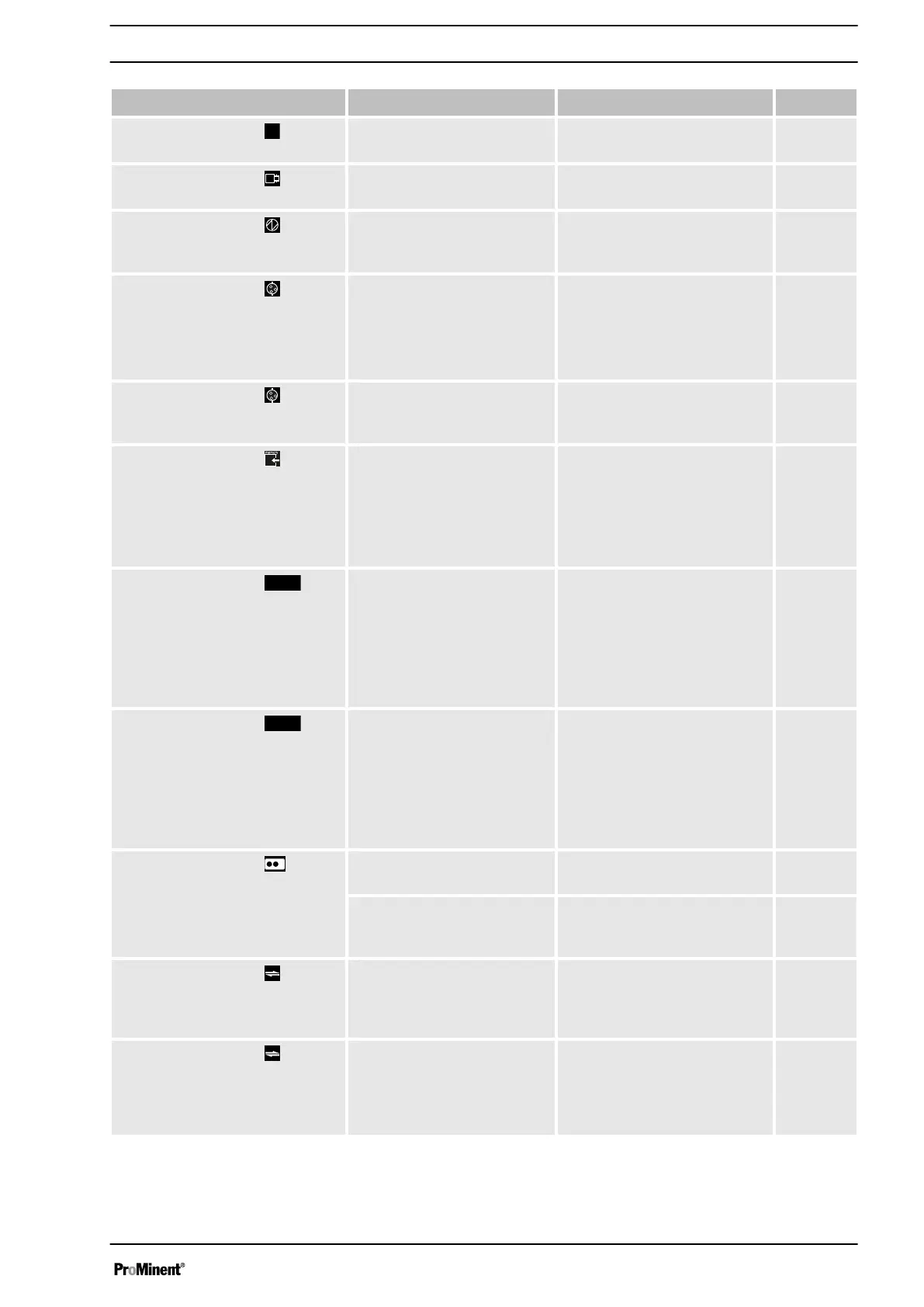

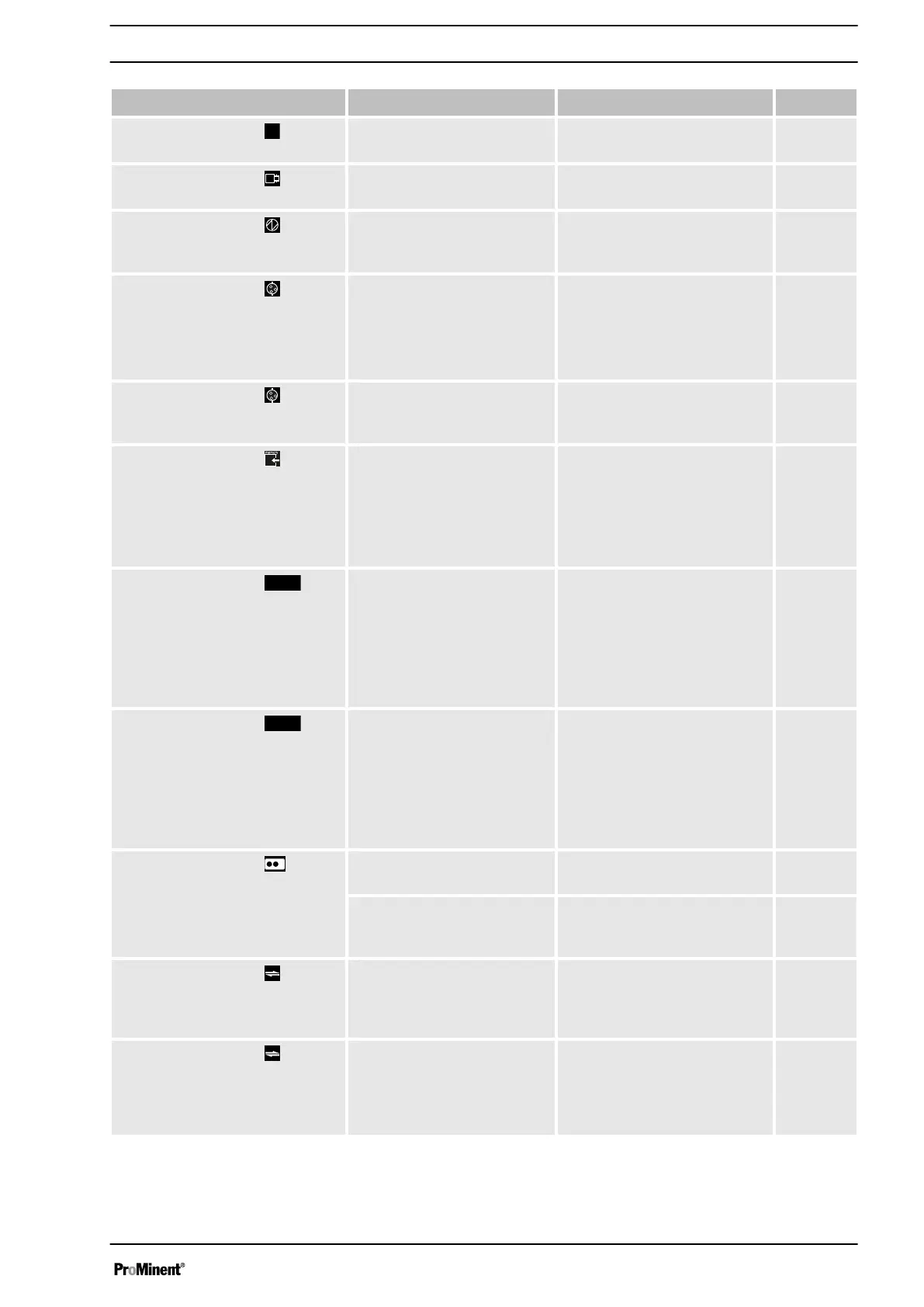

Fault description Cause Remedy Personnel

No. 11: The identifier

and the

message

‘Overload’

appear.

The pump has detected too

high a back pressure.

Rectify the cause and

acknowledge the error.

Technical

personnel

No. 12: The identifier

and the

message

‘Overload’

appear.

The current is too high. Rectify the cause and

acknowledge the error.

Technical

personnel

No. 13: The identifier and the

message

‘Power supply’

appear.

The power supply is too

high or too low or not con‐

nected.

Rectify the cause. Technical

personnel

No. 14: The identifier appears

followed by the message

‘Air in

dosinghead’

.

Gas bubbles in the liquid

end (leaks, gaseous

medium, cavitation).

Bleed the liquid end and rec‐

tify the cause. Acknowledge

the error.

Seal the system or slow the

suction stroke.

Technical

personnel

No. 15: The identifier appears

followed by the message

‘Degassing unsuccessful!’

.

Automatic bleeding was

unsuccessful

Rectify the causes and

acknowledge the error.

Technical

personnel

No. 16: The identifier

and the

message

‘Memory overflow’

appear.

The stroke tank has over‐

flowed.

Remedy the cause (such as

too low a factor, too high a

contact frequency ...), then:

Press the

[Clickwheel]

(think

of the consequences for the

process!).

Technical

personnel

No. 17: The identifier

and

the message

‘Control signal <

Imin’

appear.

The pump is in

‘Analog’

-"xx.

side band” operating mode,

a fault behaviour has been

programmed in the

‘Analog’

menu and the control cur‐

rent has fallen below 4 mA

(limit can be adjusted).

Eliminate the cause of the low

control current or

Switch the programming of

the fault behaviour to

‘off’

-

see chapter "Set up"-"Set‐

tings"-"Operating

mode"-"Analog".

Technical

personnel

No. 18: The identifier

and

the message

‘Control signal >

Imax’

appear.

The pump is in

‘Analog’

-"xx.

side band” operating mode,

a fault behaviour has been

programmed in the

‘Analog’

menu and the control cur‐

rent has risen above 20 mA

(limit can be adjusted).

Eliminate the cause of the

high control current or

Switch the programming of

the fault behaviour to

‘off’

-

see chapter "Set up"-"Set‐

tings"-"Operating

mode"-"Analog".

Technical

personnel

No. 20: The identifier

and

the message

‘Module missing’

appear.

The optional module is

missing.

Insert the optional module. Technical

personnel

Communication between the

optional module and pump

electronics is not working.

Return the pump to ProMi‐

nent.

No. 21: The identifier

and the

message

‘Module

communication’

appear.

The bus contact between

the optional module and

control room has been dis‐

connected.

Rectify the cause (cable, con‐

trol room ...)

Technical

personnel

No. 22: The identifier

and the

message

‘Internal CAN-bus’

appear.

The associated heartbeat

message was no longer

received by the power

assembly or the control part

for a certain period of time.

Rectify the cause. Technical

personnel

Troubleshooting

107

Loading...

Loading...