17.3 Viscosity

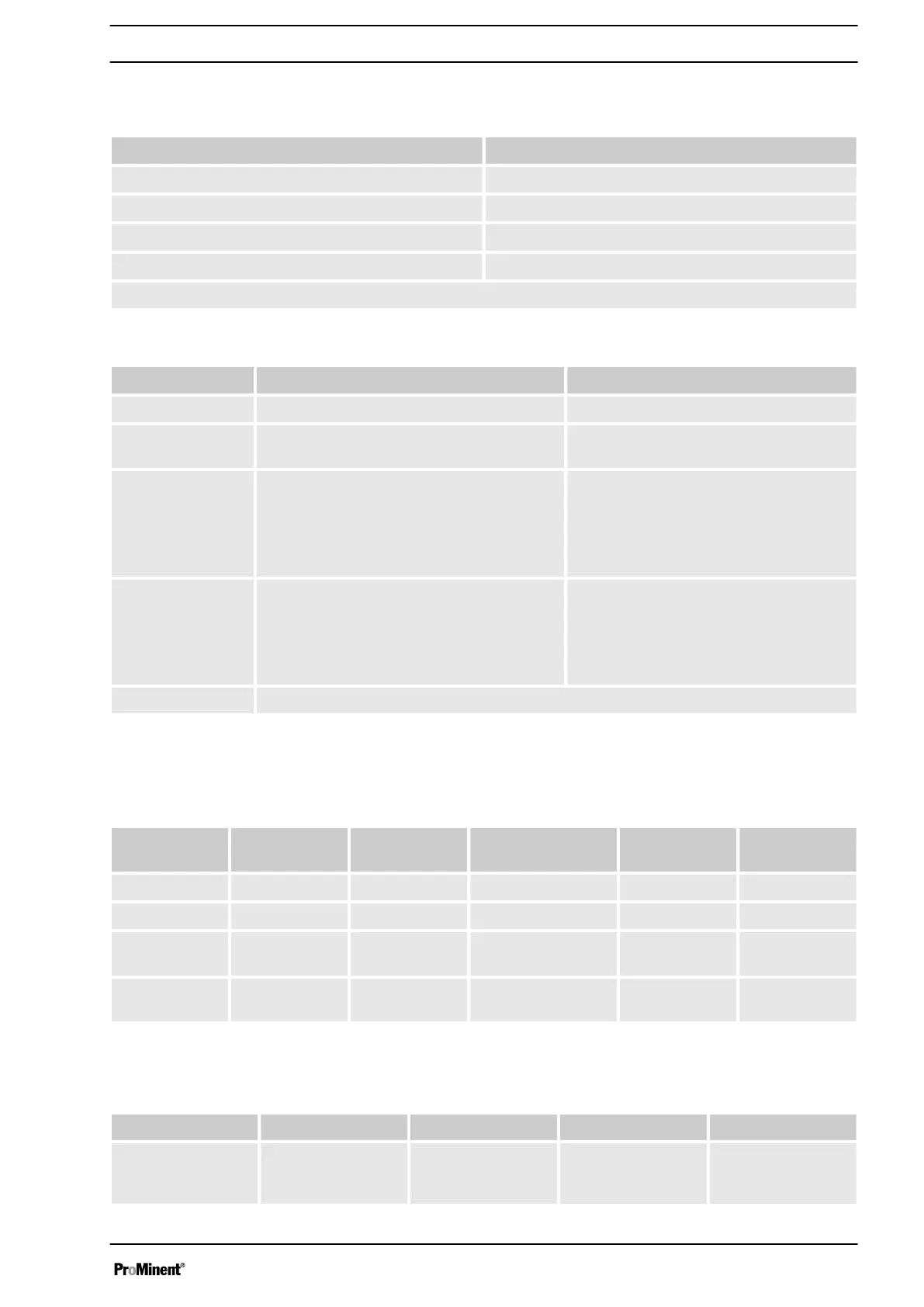

Tab. 30: The liquid ends are suitable for the following viscosity ranges:

Design Viscosity in mPas

Standard 0 ... 200

With valve springs 201 ... 500

With HV head 501 ... 3000*

Self-degassing (SEK) 0 ... 50

* Even significantly higher with correctly adjusted installation. Contact Technical Support in Heidelberg.

Tab. 31: General information on selection according to viscosity.

Viscosity in mPas Options Stroke rate (strokes/minute)

0 ... 200 No specific options required Any stroke rate.

201 ... 500 Valves fitted with springs HV1 mode: Stroke rate max. 160

strokes/minute.

501 ... 1000 Valves fitted with springs.

HV head recommended.

A positive flow is required.

Stroke length >75%.

HV 2 mode: Stroke rate max. 120

strokes/minute.

1001 ... 3000 Select an HV head.

Valves fitted with springs.

A positive flow is required.

Stroke length >75%.

HV 3 mode: Stroke rate max. 80

strokes/minute.

> 3000 Contact Customer Service to select a suitable pump.

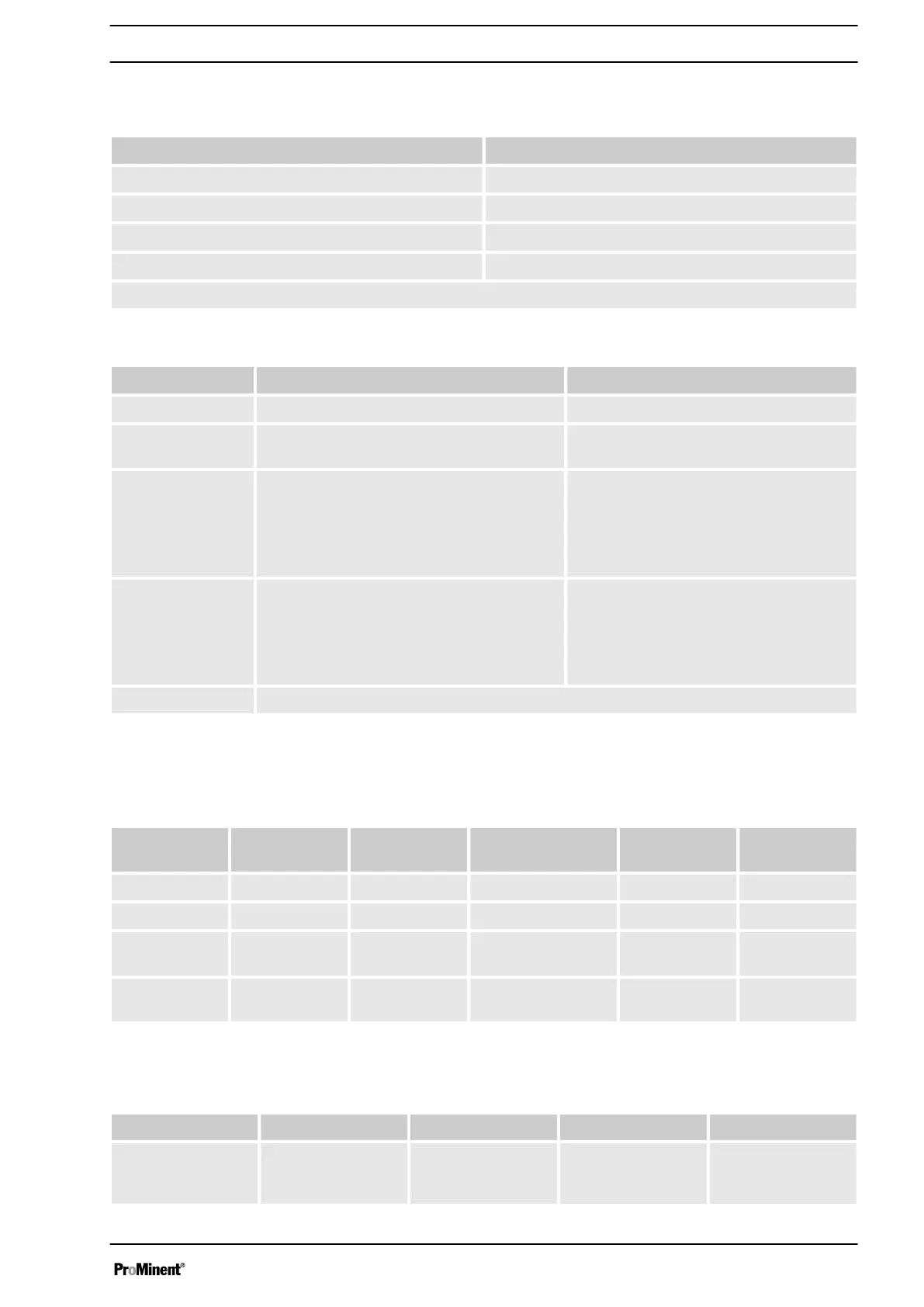

17.4 Material specifications

Design Dosing head Suction/pres‐

sure connector

Ball seat Seals Valve balls

NPT Clear acrylic PVDF PVDF PTFE Ceramic

PVT PVDF PVDF PVDF PTFE Ceramic

SST (8-12 mm) Stainless steel

1.4404

Stainless steel

1.4404

Ceramic PTFE Ceramic

SST (DN10) Stainless steel

1.4404

Stainless steel

1.4404

PTFE with carbon PTFE Ceramic

Diaphragm with PTFE coating.

Design Housing Hood Transparent cover Electronics

all Polyphenyl ether

(PPE with fibre‐

glass)

Polyphenyl ether

(PPE with fibre‐

glass)

Polycarbonate Electronic compo‐

nents

Liquid ends

Pump

Technical data

117

Loading...

Loading...