15.2 Faults with error message

15.2.1

Fault messages on the LCD screen

In the event of a fault:

n the red LED display lights up.

n an identifier and a message appear on the LCD screen.

n the pump stops.

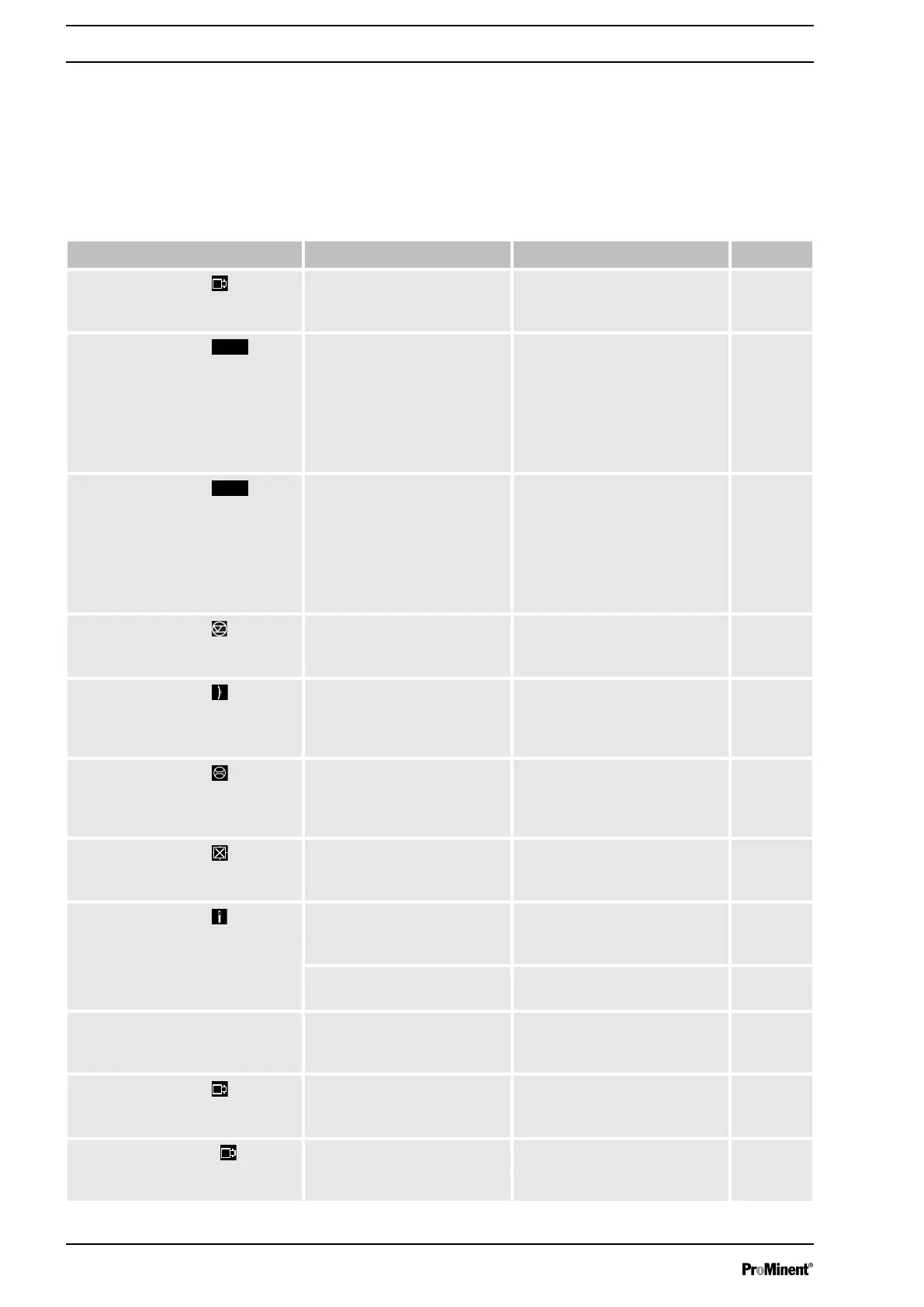

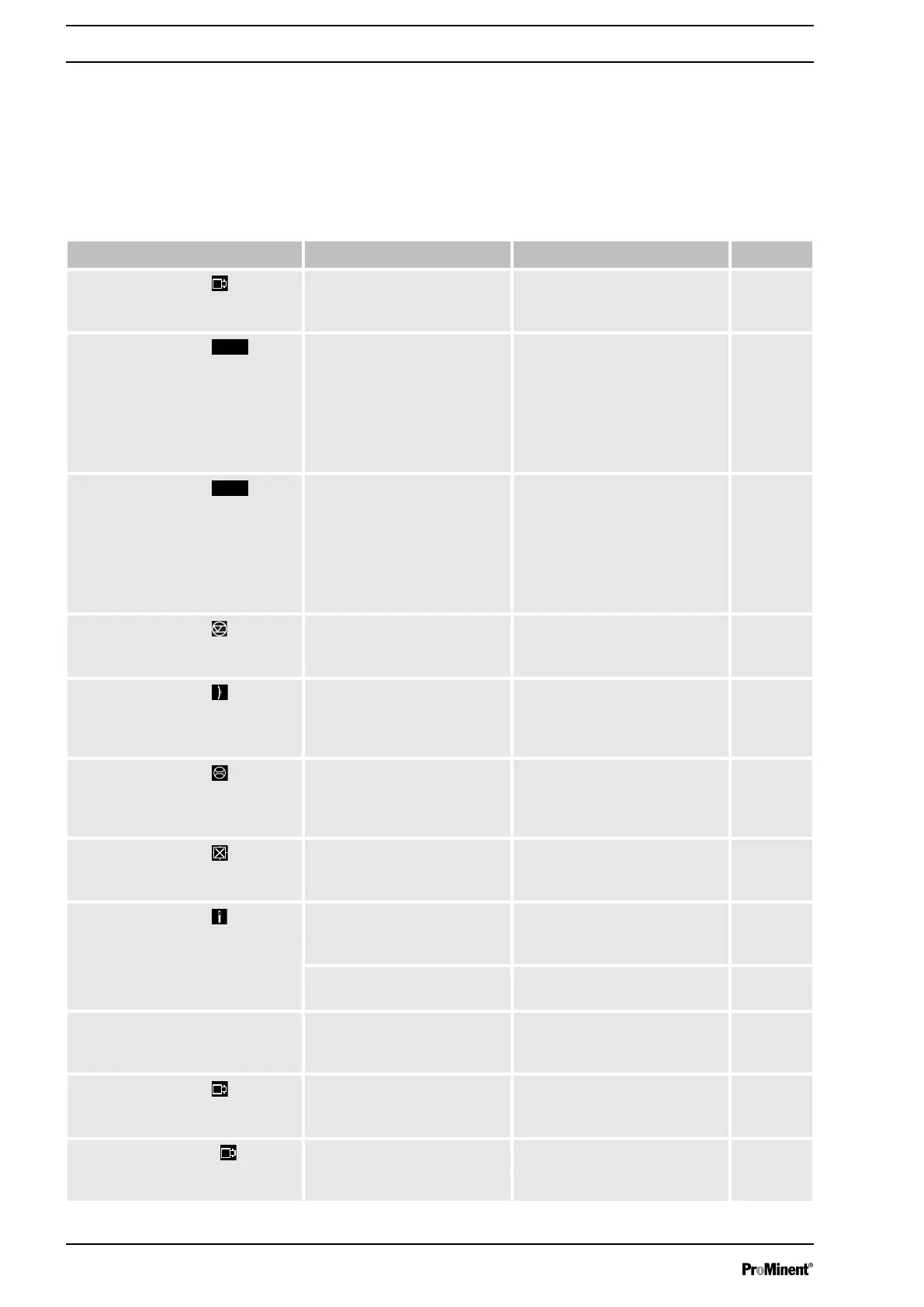

Fault description Cause Remedy Personnel

No. 0: The identifier appears

followed by the message

‘System error’

.

System or EPRom error Return the pump to ProMi‐

nent.

No. 1: The identifier

appears followed by the mes‐

sage

‘Input signal < 4 mA’

.

The pump is in

‘Analog’

operating mode, a fault

behaviour has been pro‐

grammed in the

‘Analog’

menu and the control cur‐

rent has fallen below 4 mA.

Eliminate the cause of the low

control current or

Switch the programming of

the fault behaviour to

‘off’

-

see chapter "Set up"-"Set‐

tings"-"Operating

mode"-"Analog".

Technical

personnel

No. 2: The identifier

appears followed by the mes‐

sage

‘Input signal > 20 mA’

.

The pump is in

‘Analog’

operating mode, a fault

behaviour has been pro‐

grammed in the

‘Analog’

menu and the control cur‐

rent has risen above 20 mA.

Eliminate the cause of the

high control current or

Switch the programming of

the fault behaviour to

‘off’

-

see chapter "Set up"-"Set‐

tings"-"Operating

mode"-"Analog".

Technical

personnel

No. 3: The identifier

appears

followed by the message

‘Level

error!’

.

The fluid level in the storage

tank has reached "Liquid

level low 2nd stage".

Top up the storage tank. Technical

personnel

No. 4: The identifier

appears

followed by the message

‘Diaphragm rupture’

.

The diaphragm is broken. Replace the diaphragm and

clean the diaphragm rupture

indicator, refer to the "Repair"

chapter.

Technical

personnel

No. 5: The identifier

appears

followed by the message

‘Defective stroke met.’

.

The metering monitor

reported more defective

strokes than was set in the

‘Inputs/Outputs’

menu.

Press the

[Clickwheel]

.

Investigate and clear the

cause.

Technical

personnel

No. 6: The identifier

appears

followed by the message

‘Sensor error’

.

Sensor faulty Return the pump to ProMi‐

nent.

No. 7: The identifier

"Tem‐

perature" appears followed by

the message

‘Temperature’

and

the pump remains idle.

The ambient temperature is

too high or too low.

Change the ambient tempera‐

ture. The pump starts up

automatically.

Technical

personnel

The temperature is too high. Rectify the cause. The pump

starts up automatically.

Technical

personnel

No. 8: No identifier appears but

the message

‘Initialisation’

appears.

Pump restart, initialisations

incomplete.

Pump restart.

No. 9: The identifier

appears

followed by the message

‘Solenoid not connected’

.

The solenoid is not con‐

nected.

Return the pump to ProMi‐

nent.

No. 10: The identifier

appears

followed by the message

‘Parameter wrong!’

.

An incorrect parameter has

been entered.

Correct the parameter. Technical

personnel

Troubleshooting

106

Loading...

Loading...