9.2 HMI operating unit

Connect the HMI to the CAN socket above the LEDs of the pump

base if the pump is operated with HMI.

If the pump is operated without HMI, then plug the sealing cap sup‐

plied into the CAN socket above the LEDs of the pump base.

CAUTION!

Risk of short circuiting

A short circuit may occur in the pump if liquid pene‐

trates into the CAN socket.

– Always plug a CAN plug or the sealing cap

supplied into the CAN socket.

CAUTION!

Danger of malfunction

Incorrect operation via the CAN bus will lead to

malfunctions.

– Do not connect any other control (e.g. DXCa)

to the CAN socket when operating with HMI

connected.

9.3 Description of the terminals

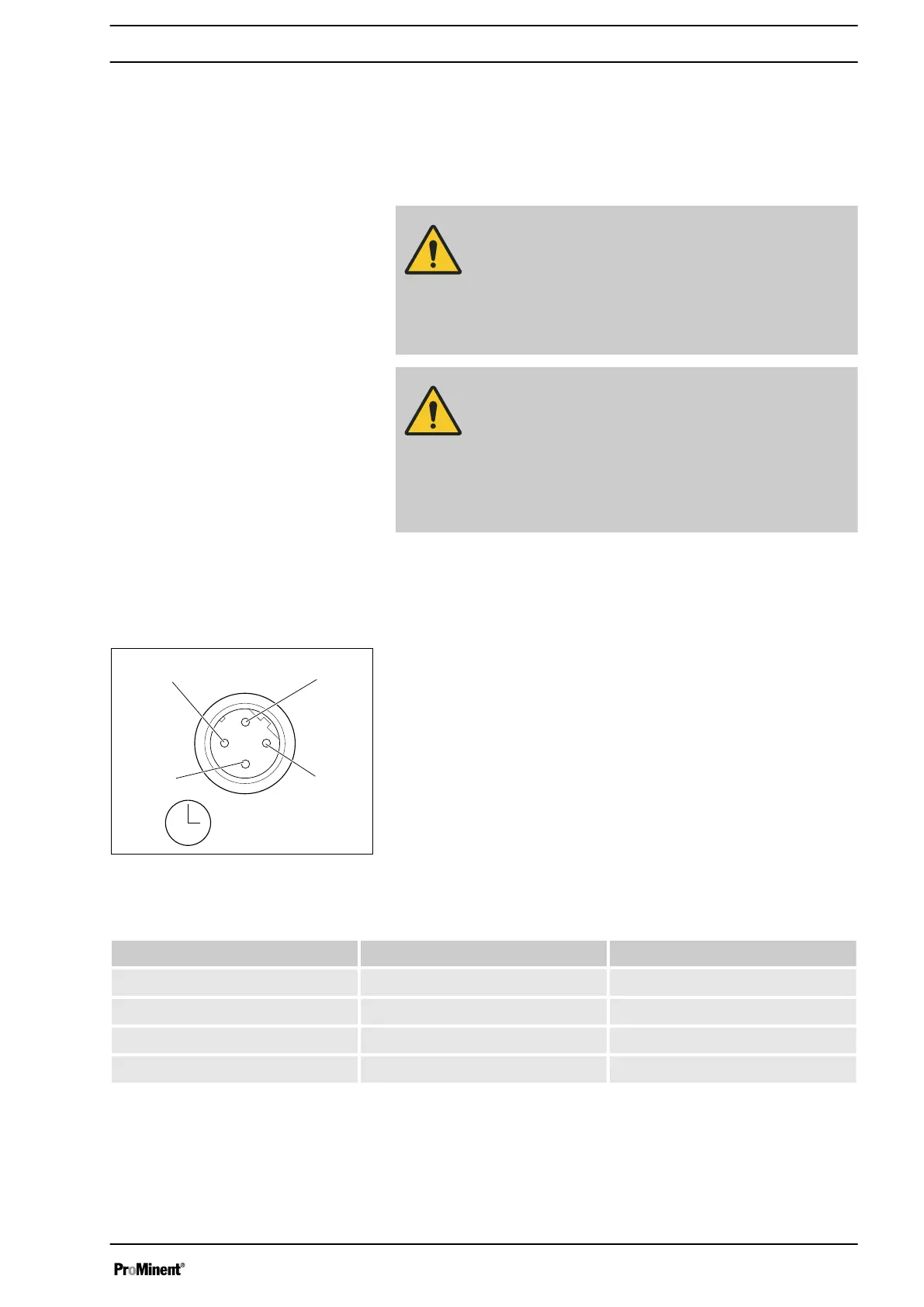

9.3.1

"Config I/O" terminal

There is an option to transmit the signals of 3 potential-free con‐

tacts as inputs I: to the pump via the "Config I/O" terminal or issue

contact signals as Outputs O:.

Tab. 3: Pin assignment

Pin Assignment 4-wire cable

1 Config I/O 1 brown

2 Config I/O 2 white

3 Config I/O 3 blue

4 GND black

Fig. 12: "Config I/O" terminal, pin

assignment

Installation, electrical

37

Loading...

Loading...