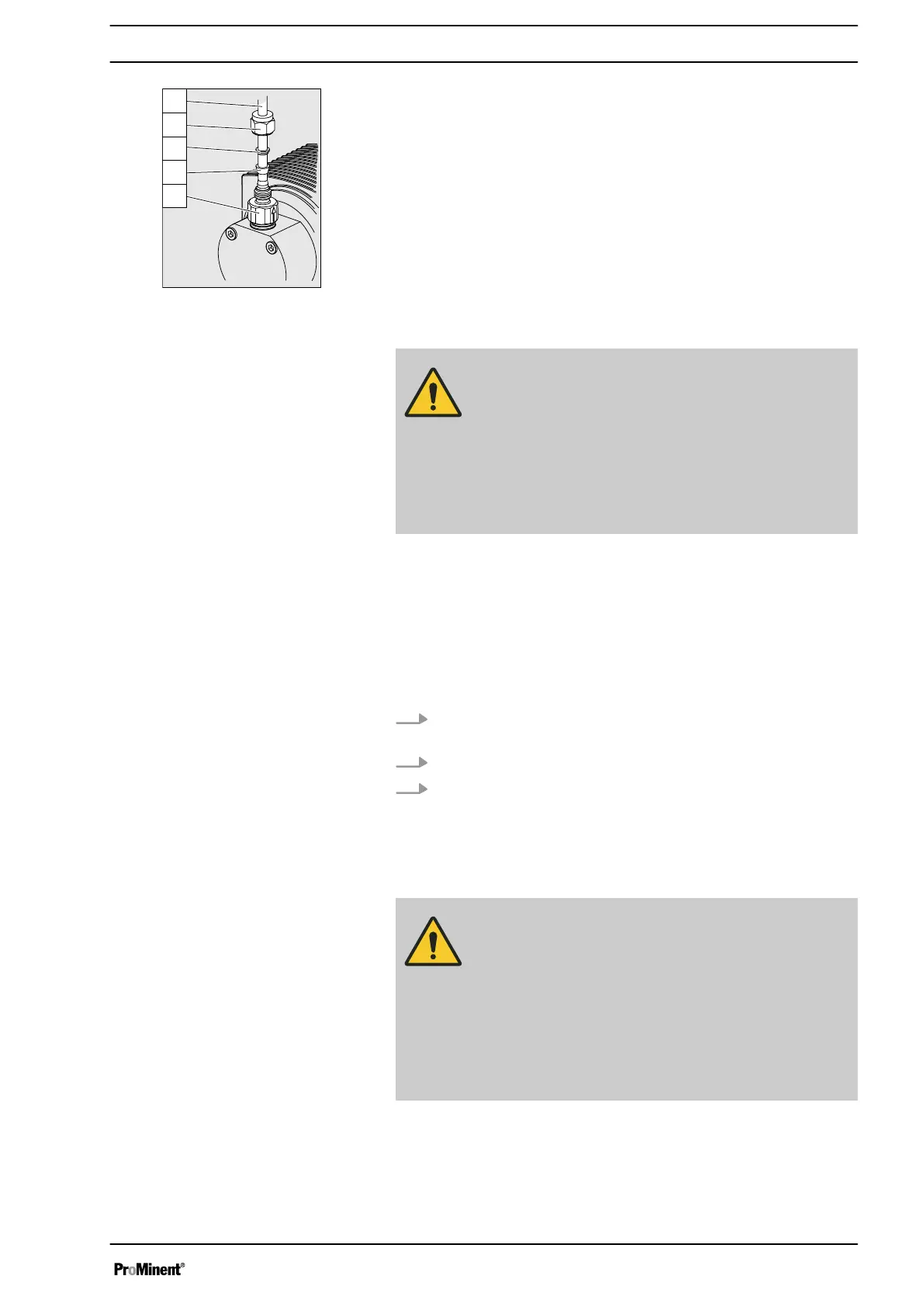

1 Pipe

2 Union nut

3 Rear clamp ring

4 Front clamp ring

5 Valve

CAUTION!

Warning of feed chemical spraying around

Connections can come loose in the event that

hose lines are installed incorrectly on stainless

steel valves.

–

Only use PE or PTFE hose lines.

– In addition, insert a stainless steel support

insert into the hose line.

8.1.2 Installation with metering pumps with degassing

All the installation and safety information for metering pumps

without degassing also applies.

A return line is also connected in addition to the suction and pres‐

sure line.

1. Attach the hose line to the return hose sleeve or to the liquid

end vent valve. PVC hose, soft, 6x4 mm is recommended.

2. Feed the free end of the return line into the supply tank.

3. Shorten the return line so that it is not immersed in the feed

chemical in the supply tank.

8.2

Basic installation notes

CAUTION!

Danger resulting from rupturing hydraulic compo‐

nents

Hydraulic components can rupture if the maximum

permissible operating pressure is exceeded.

– Never allow the metering pump to run against

a closed shut-off device.

–

With metering pumps without integral relief

valve: Install a relief valve in the discharge line.

Fig. 10: SST designs

Installing hose lines - SST design

Installation of the return line

Safety notes

Installation, hydraulic

33

Loading...

Loading...