17 Technical data

17.1

Performance data

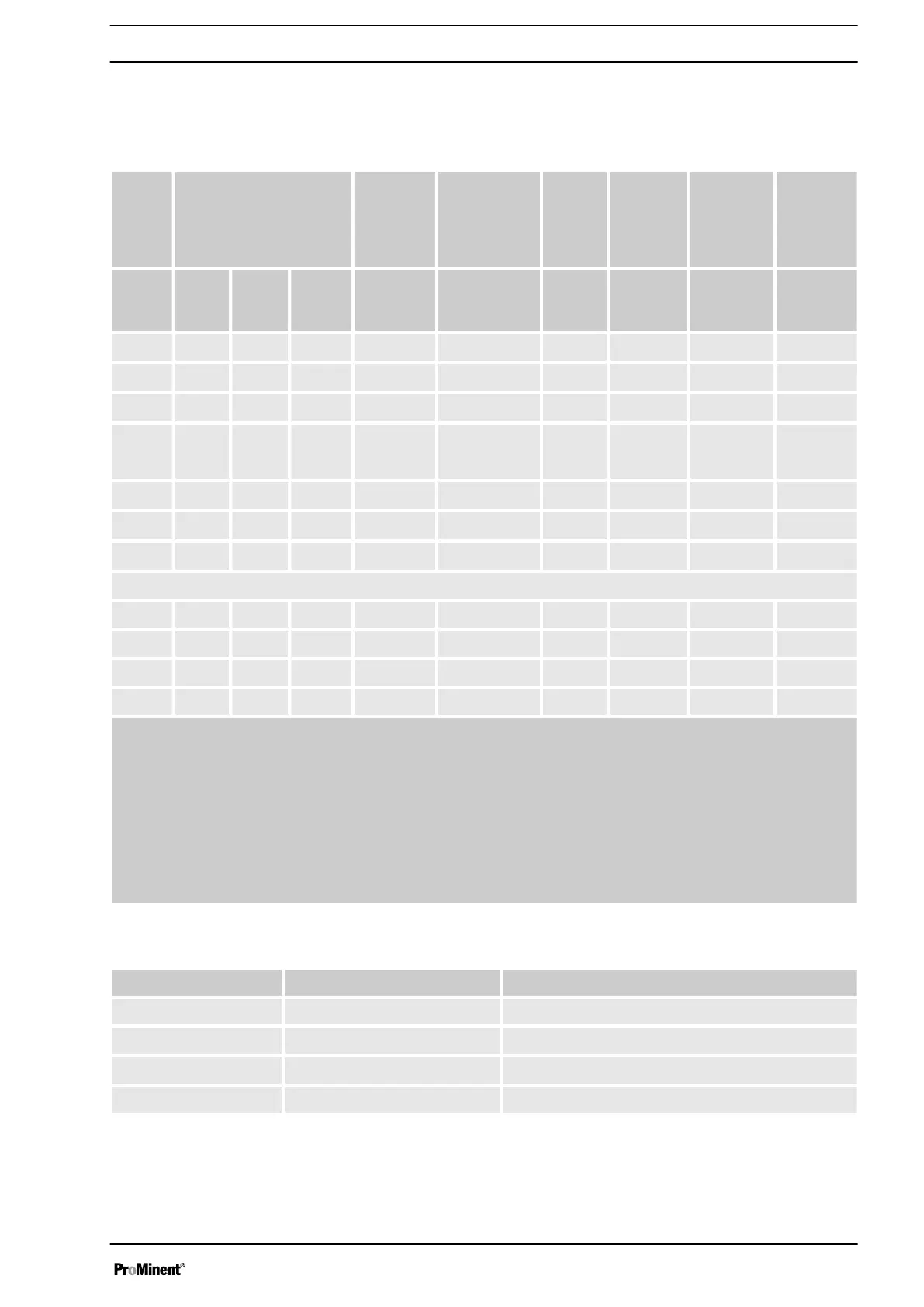

Tab. 28: At 200 strokes/minute and 100% stroke length

Liquid

end

type

Minimum pump capacity Max.

stroke

rate

Connector

size

outer Æ x

inner Æ

Suction

lift*

Priming

lift

Max. pri‐

ming pres‐

sure on

the suc‐

tion side

1

Weight

bar l/h ml/

stroke

Strokes/m

in

mm m

water

column

m water

column

bar kg

2508 25 7.5 0.63 200 8x4 / 6x4 5 3.5 / 3.0 12.5

11

2

/ 10

1608 16 7.8 0.65 200 8x5 / 8x7 5 3.5 / 3.0 8

11

2

/ 10

1612 16 12.0 1.00 200 8x5 / 8x7 6 3.0 / 2.5 8

11

2

/ 10

1020 10 19.6 1.63 200 12x9 / 12x10 5 3.5 / 3.0 5

11

2

/ 10

10 / 11

2

0730 7 29.4 2.40 200 12x9 / 12x10 5 4.0 / 3.5 3.5

11

2

/ 10

0450 4 49.0 4.08 200 DN 10 3 2.5 / 2.5 2

11

2

/ 10

0280 2 78.5 6.54 200 DN 10 2 3.0 / 3.0 1

11

2

/ 10

Design with self-degassing dosing head without bypass**

1608 16 7.0 0.60 200 8x5 3 3.0 8 10

1612 16 10.0 0.80 200 8x5 2 1.4 8 10

1020 10 15.0 1.25 200 12x9 2 1.5 5 10

0730 7 27.5 2.30 200 12x9 2 1.6 3.5 10

* Suction lift with a filled suction line and filled liquid end

** The performance data stated represents guaranteed minimum values, calculated using water as the

medium at room temperature.

1

If the pump is fitted with an SER head and priming pressure is being applied, then the pump may only be

operated in Automatic OFF mode.

2

With stainless steel design

Metering pumps with dosing heads for higher-viscosity media (HV) have a

10 ... 20% lower dosing rate and

are not self-priming. Connector G 3/4-DN 10 with hose sleeve d16-DN10.

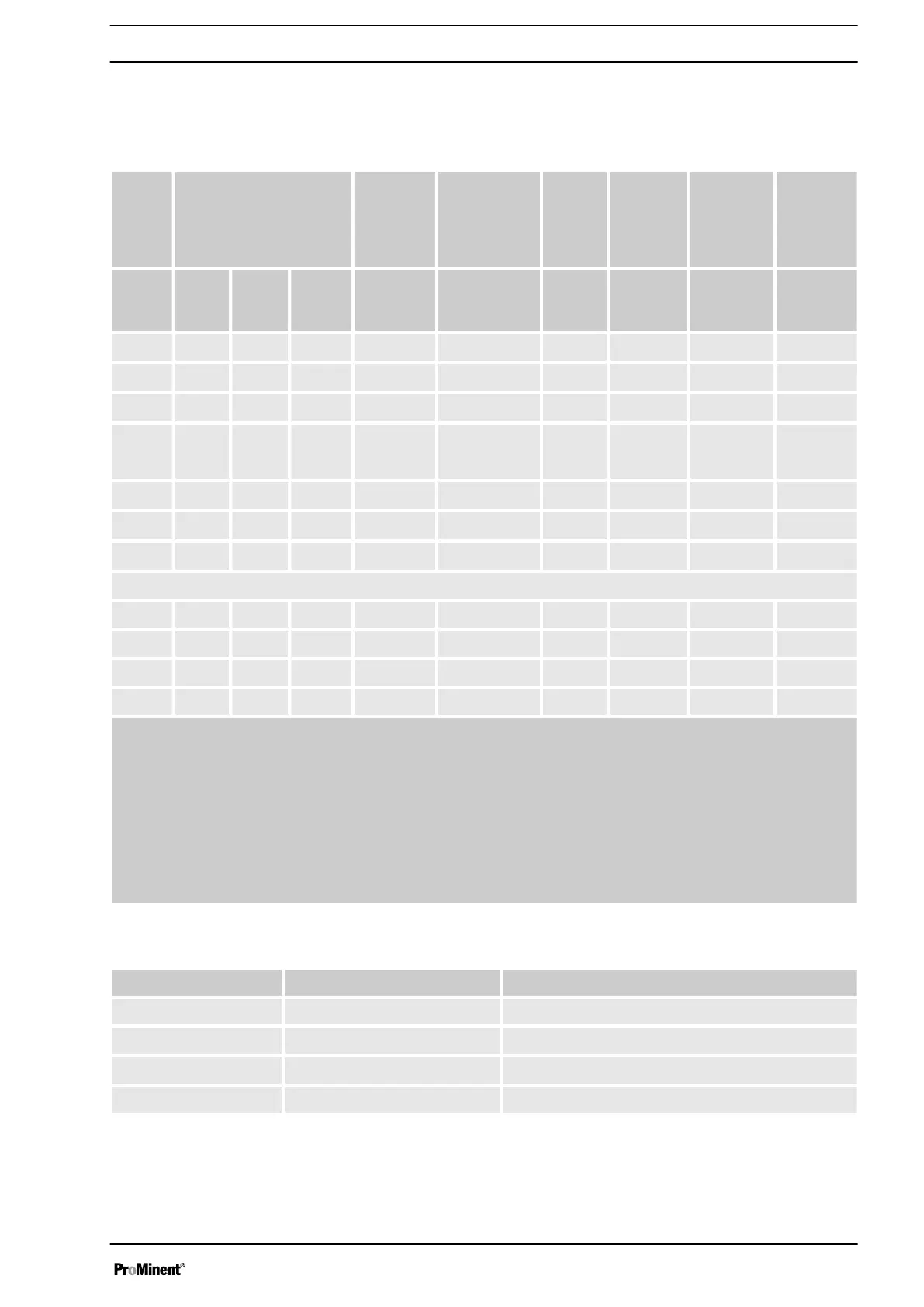

Material Connector Design

Plastic 8 ... 12 mm Hose squeeze connector

DN 10 d16 DN 10 hose sleeve

Stainless steel 6 ... 12 mm

Swagelok

®

system

DN 10 Rp 3/8 insert

Design of connectors

Technical data

115

Loading...

Loading...