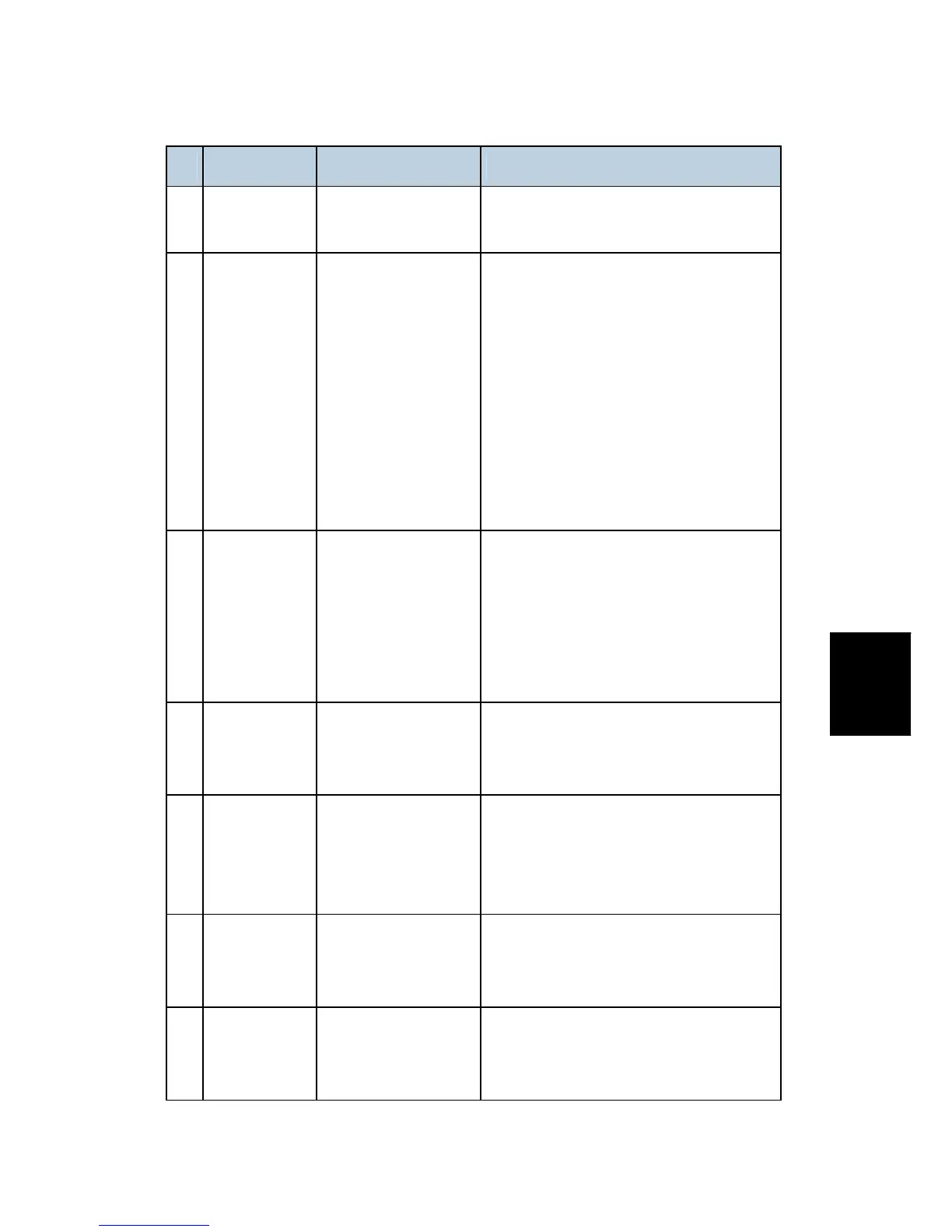

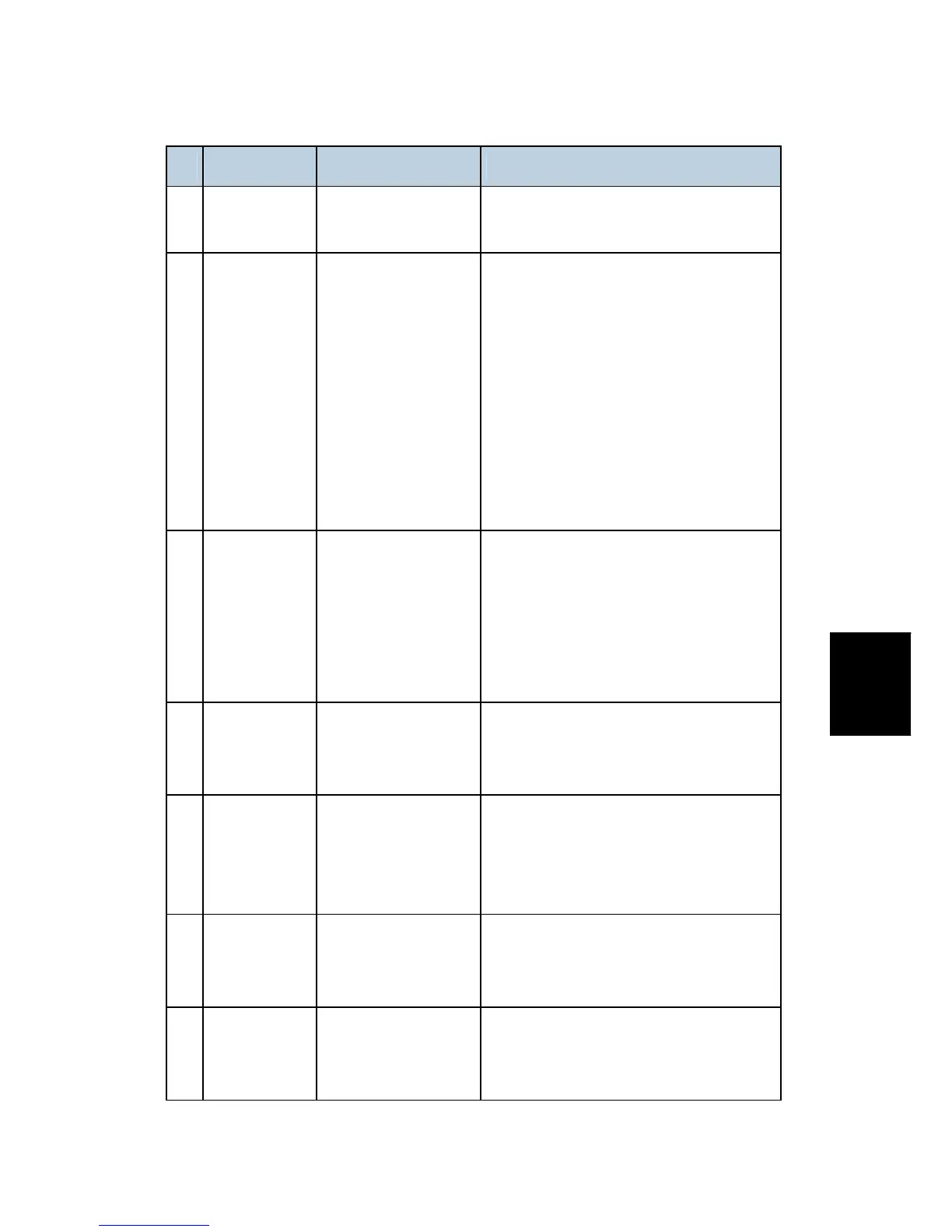

Process Control Error Conditions

SM Appendix 5-3 D037/D038/D040/D041

Appendix:

Process

Control Error

Conditions

No. Result Description Possible Causes/Action

1. Replace the development unit.

2. Replace the BCU board.

53

ID sensor

coefficient

(K5) detection

error

Not enough data can

be sampled.

Solid image is not sufficient density:

1. Retry the process control.

2. Replace the ID sensors.

3. Replace the BCU board.

Solid image is O.K.

1. Replace the ID sensors.

2. Replace the BCU board.

ID sensor is dirty:

1. Clean the ID sensors.

2. Retry the process control.

54

ID sensor

coefficient

(K5)

maximum/

minimum error

When the K5 is more

than the value of

SP3-362-003 or less

than the value of

SP3-362-004, the

error 54 is displayed.

ID sensor pattern density is too high

or low.

ID sensor or shutter is defective.

Same as 53

55

Gamma error:

Maximum

Gamma is out of

range. 5.0 < Gamma

ID sensor pattern density is too high.

Hardware defective.

Same as 53

56

Gamma error:

Minimum

Gamma is out of

range.

Gamma < 0.15

ID sensor pattern density is too low.

Hardware defective.

1. Same as 53

2. Replace the toner hopper unit.

57

Vk error:

Maximum

Vk is out of range.

150 < Vk

ID sensor pattern density is too low.

Hardware defective.

Same as 53

58

Vk error:

Minimum

Vk is out of range.

Vk < –150

ID sensor pattern density is too high.

Background dirty

Hardware defective

Loading...

Loading...