2.3.3 Backup roller mechanism

Because this machine employs a photoconductor belt,

the gap between the OPC and development unit,

cleaning unit, or OPC cleaning brush changes due to the

flexibility of the OPC belt. To cope with this problem, the

OPC unit has back-up rollers at each affected position.

Cleaning back-up roller

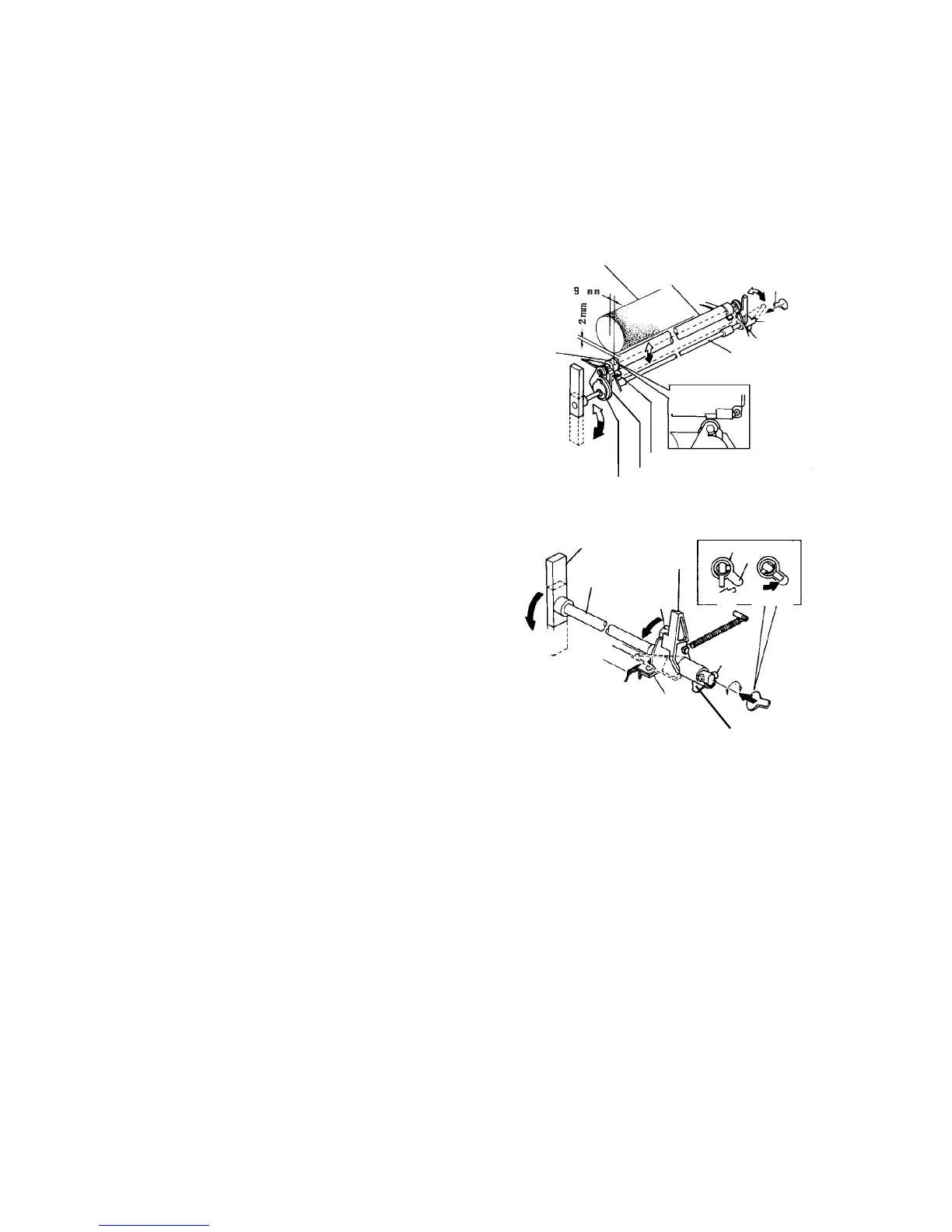

The cleaning backup roller is positioned 9 mm from the

center of the cleaning roller. This widens the contact

area of the cleaning roller and improves cleaning

efficiency.

The lock pawl on the rear of the release shaft engages

the OPC unit with the main body rear frame. This

prevents the OPC unit from being pulled out while the

back-up roller is set.

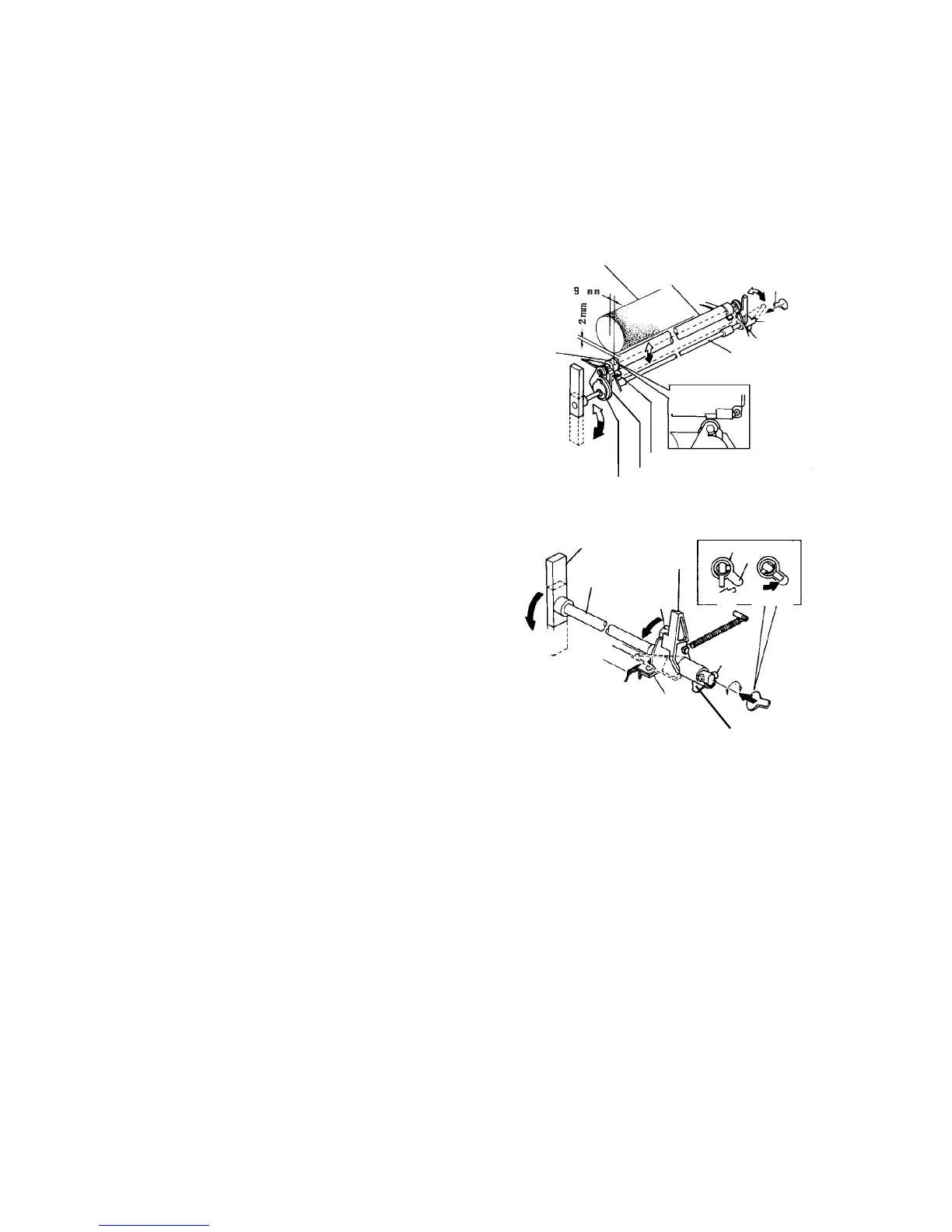

When the lever is turned clockwise, the back-up roller

moves down. At the same time, the pin mounted on the

rear of the release shaft turns the stopper and lock pawl.

The stopper is in contact with the holder and unit side

plate to restrict the turning range of the lever. When the

lock pawl meets the cutout of the main body rear frame,

the OPC unit can be pulled out.

Release shaft

Cleaning roller

Stopper

Cutout

Set

Release

Pin

Side plate

Holder

Stopper

Release

lever

Release shaft

Lock pawl

Loading...

Loading...