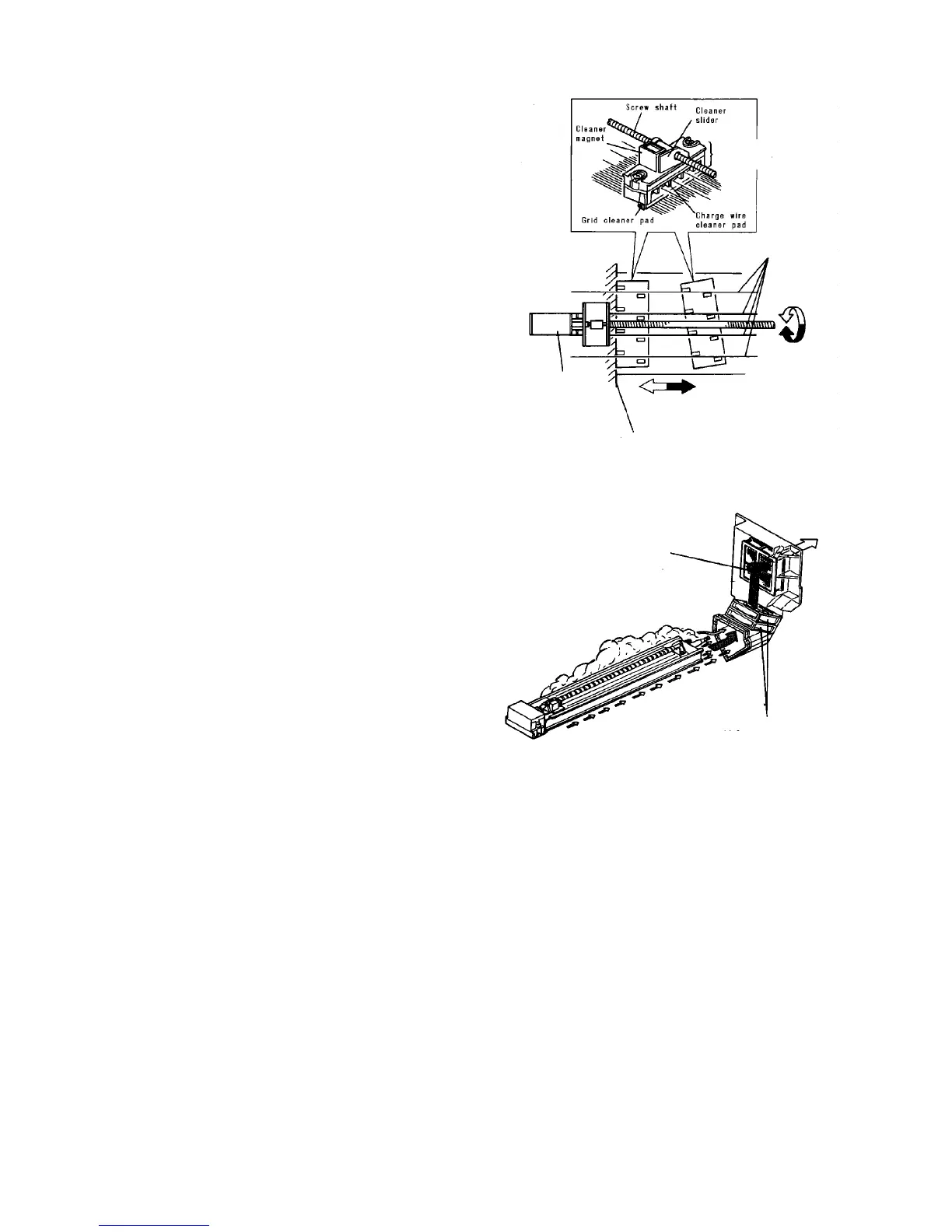

2.4.3 Cleaner mechanism

The cleaner cleans the charge wires and grid wires to

prevent fluctuation in photoconductor surface potential

caused by contamination.

The cleaner unit is set with the feed screw and can be

moved to the front and rear of the unit by turning the

cleaner motor.

After the cleaner unit leaves its home position, the

cleaner magnet is attracted and in contact with the

cleaner slider. This makes the cleaner unit slanted so

that the cleaner pads touch the charge wires. At the

home position, attraction on the magnet is released by

contact of the cleaner unit and the end block. The

cleaner pad separates from the charge wires to prevent

a change in the wire position from causing a contact with

the pad.

Cleaning is conducted when the main switch is turned

on after 20,000 or more copies have been made.

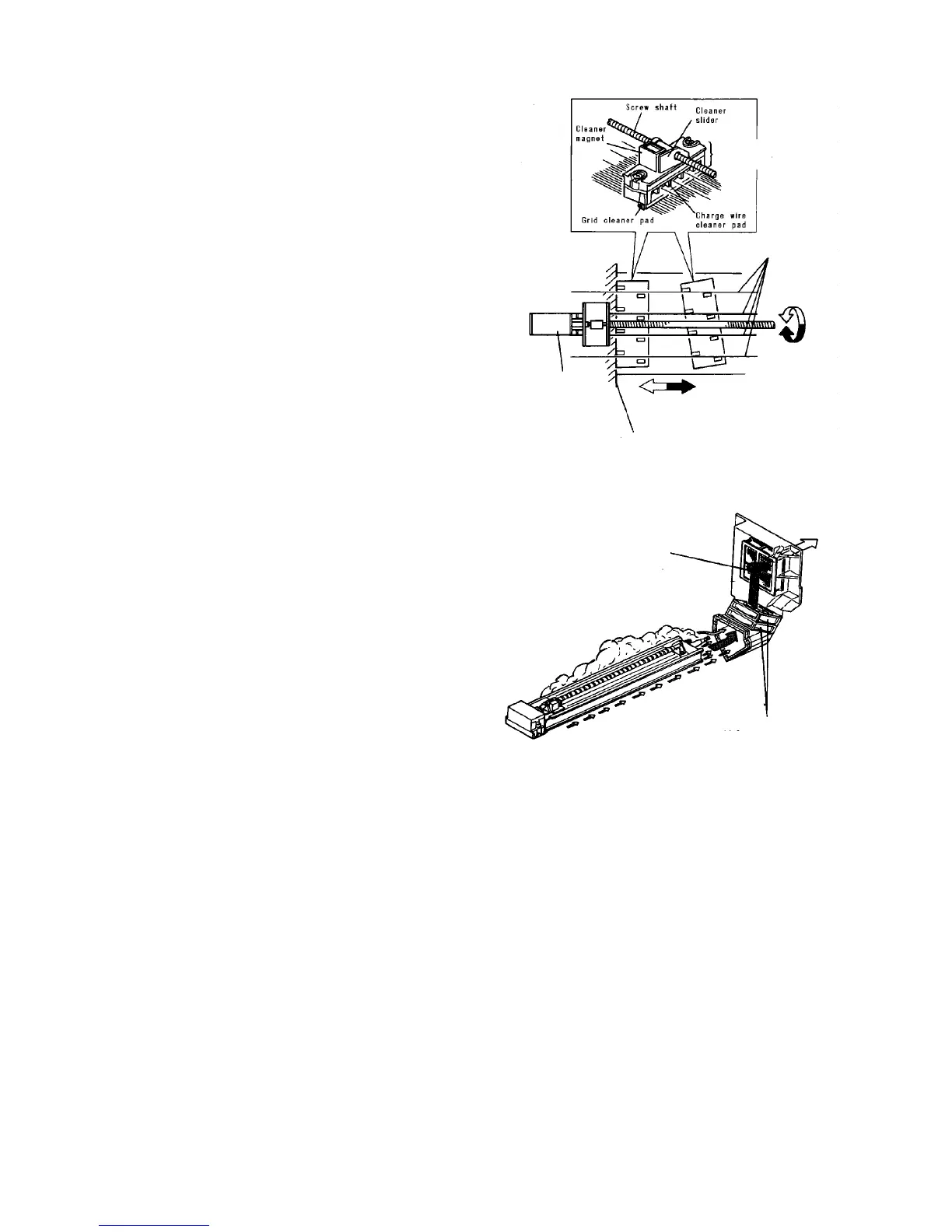

2.4.4 Ozone exhaust mechanism

If ozone generated by discharge is allowed near the

photoconductor, image smearing can result. To prevent

the build up of ozone near the photoconductor, a duct

and two fans are provided.

The ozone gas is drawn and filtered by the ozone filter

on the rear cover and discharged as clean air. When the

main switch is ON, the two motors start. When the main

switch is turned OFF, these motors continue to run for

about 30 minutes. This is controlled by the timer board.

The outside fan keeps on turning for 8 to 10 hours

more. It is powered by the internal battery.

Cleaner motor

Home position

Forward

Charge corona wire

Cleaner

unit

Ozone filter

Ozone exhaust fan

Loading...

Loading...