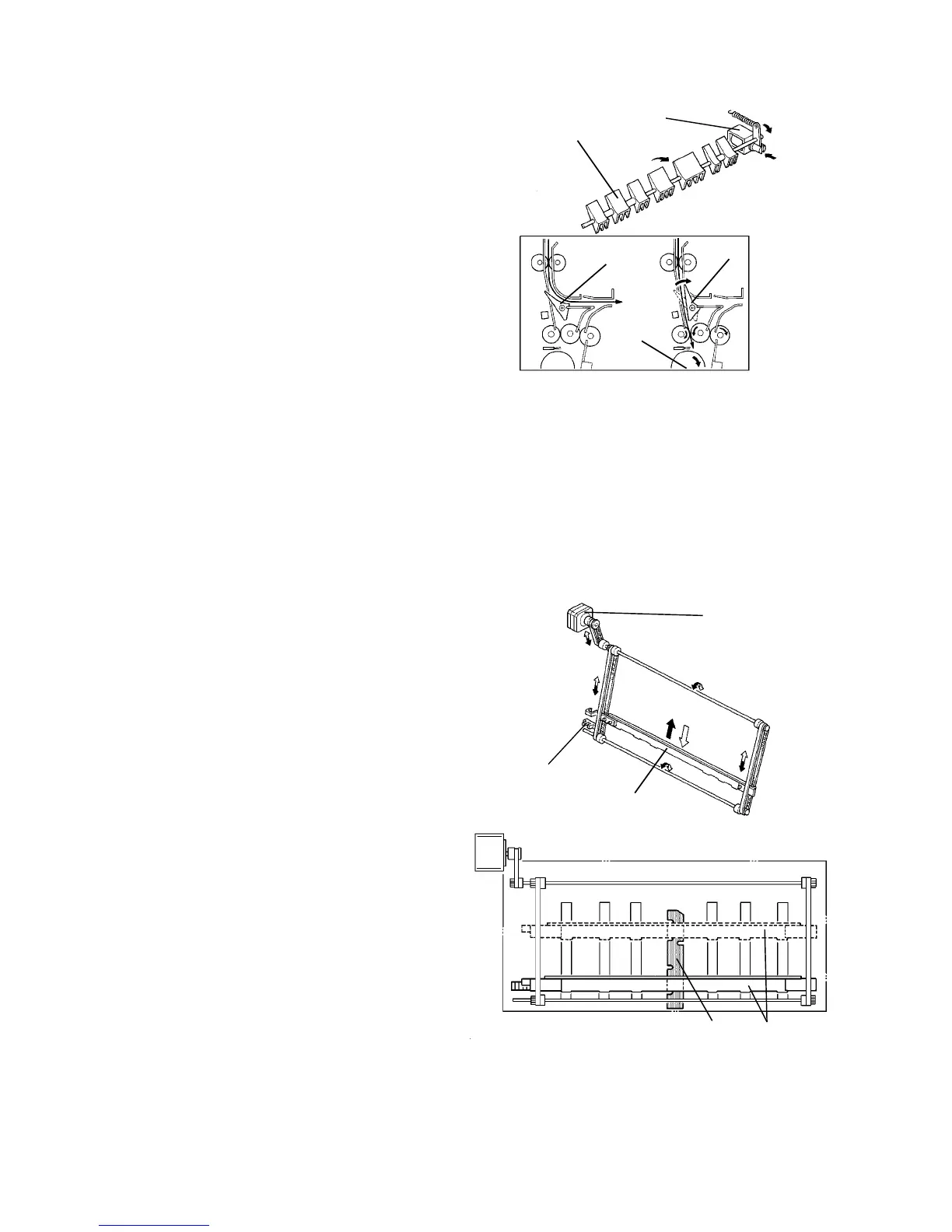

2.17.3 Inverter junction gate operation

In the single side copy mode, if one of the finishing

modes is selected, the inverter junction gate solenoid [A]

is energized when the copier exit sensor (the eject

junction sensor) detects the first copy.

The junction gate pawls [B] are switched so that copy

paper is directed into the inverter tray (downward). The

inverter guide brush roller [C] is always rotating while the

finisher is in operation, and it presses the copy paper

against the paper guide plate and helps guide the copy

paper to the inverter tray.

Soon after the copy paper enters the inverter tray, it is

moved up and returned to the inverter guide brush roller

by the inverter stopper operation. (See the next section

for the inverter stopper operation.) Although the inverter

guide brush roller is rotating against the paper

transportation at this time, the copy paper passes the

roller and is sent to the finisher part because of the soft

brush surface of the inverter guide brush roller and a

clearance between the roller and paper guide plate.

In the duplex copy mode, copies are sent to the finisher

regardless of the finishing mode selection. In this case,

the inverter junction gate solenoid remains

de-energized, so that the junction gate pawls guide the

copies to the right. The copies are sent to the finisher

part and fed out to the shift tray without paper inversion.

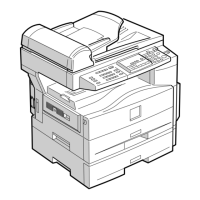

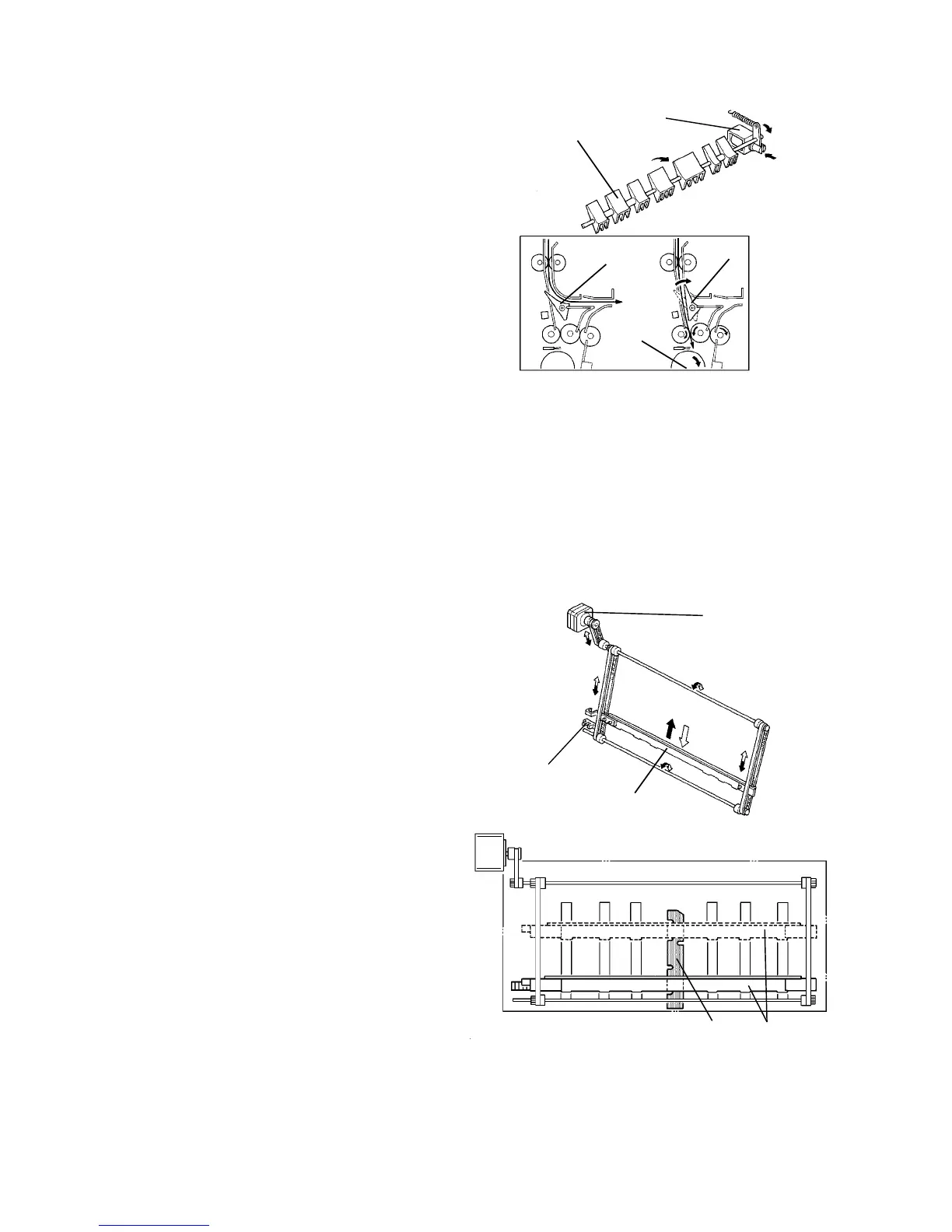

2.17.4 Inverter stopper operation

When the finisher ON signal is sent to the inverter

control PCB from the copier, the stopper plate [C] is

moved up from its home position by the stopper drive

motor [A] (a stepper motor) via timing belts. The stop

position of the stopper plate is set by the pulse signal

from the inverter control PCB. (The pulses are

determined based on the paper size signal from the

copier.) The stopper plate waits for the paper entering

into the inverter tray at the stop position.

A decal [D] indicating paper sizes is attached in the

inverter tray to check the stop position of the stopper

plate for each paper size.

After copy paper enters the inverter tray, the leading

edge of the paper hits the inverter stoppers, which are

fixed in the stopper plate and sponge material to absorb

the shock of the hit. Soon after this, the stopper drive

motor moves up the stopper plate slightly. The copy

paper is moved up and returned. Then the stopper plate

is returned to the stop position. The stopper plate

repeats this operation for each paper entering the

inverter tray.

When the finisher ON signal turns OFF, the stopper

drive motor rotates in the opposite direction to return the

stopper plate to its home position. The stopper home

position sensor [B] detects the feeler fixed on the

stopper plate.

[D] [C]

[A]

[B]

[C]

[B]

[B]

[A]

[B]

[C]

Loading...

Loading...