ROBOTAPE 50 CFA

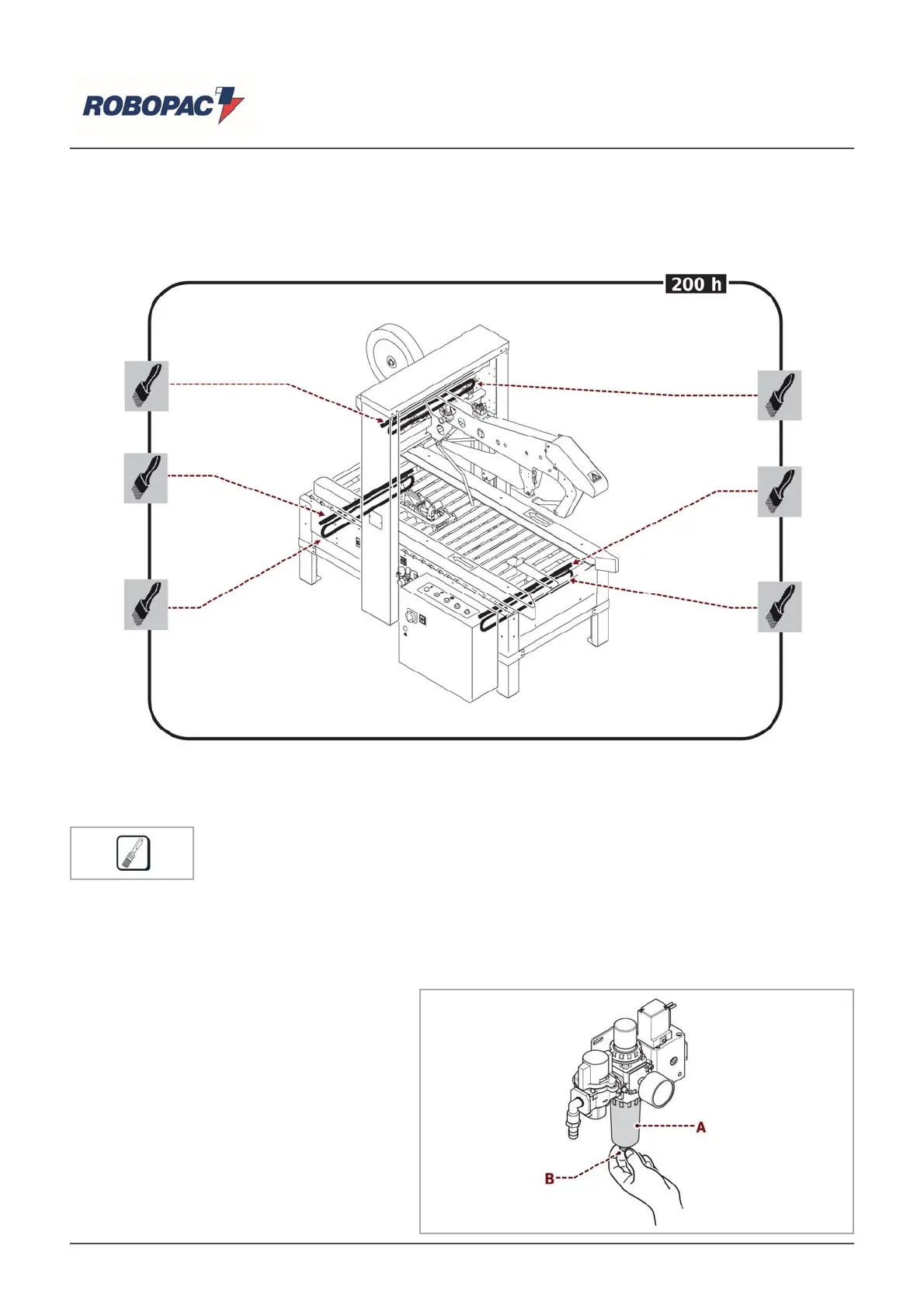

7.3. LUBRICATION POINT DIAGRAM

The following diagram shows the main components and the frequency of the lubrication interventions.

Symbol and Description

Smear with

reas

Keep to the recommended lubrication frequency to get top machine performances and a longer

o

eratin

life.

Use lubricants (oils or grease) recommended by the manufacturer or with similar chemical-

h

sical features.

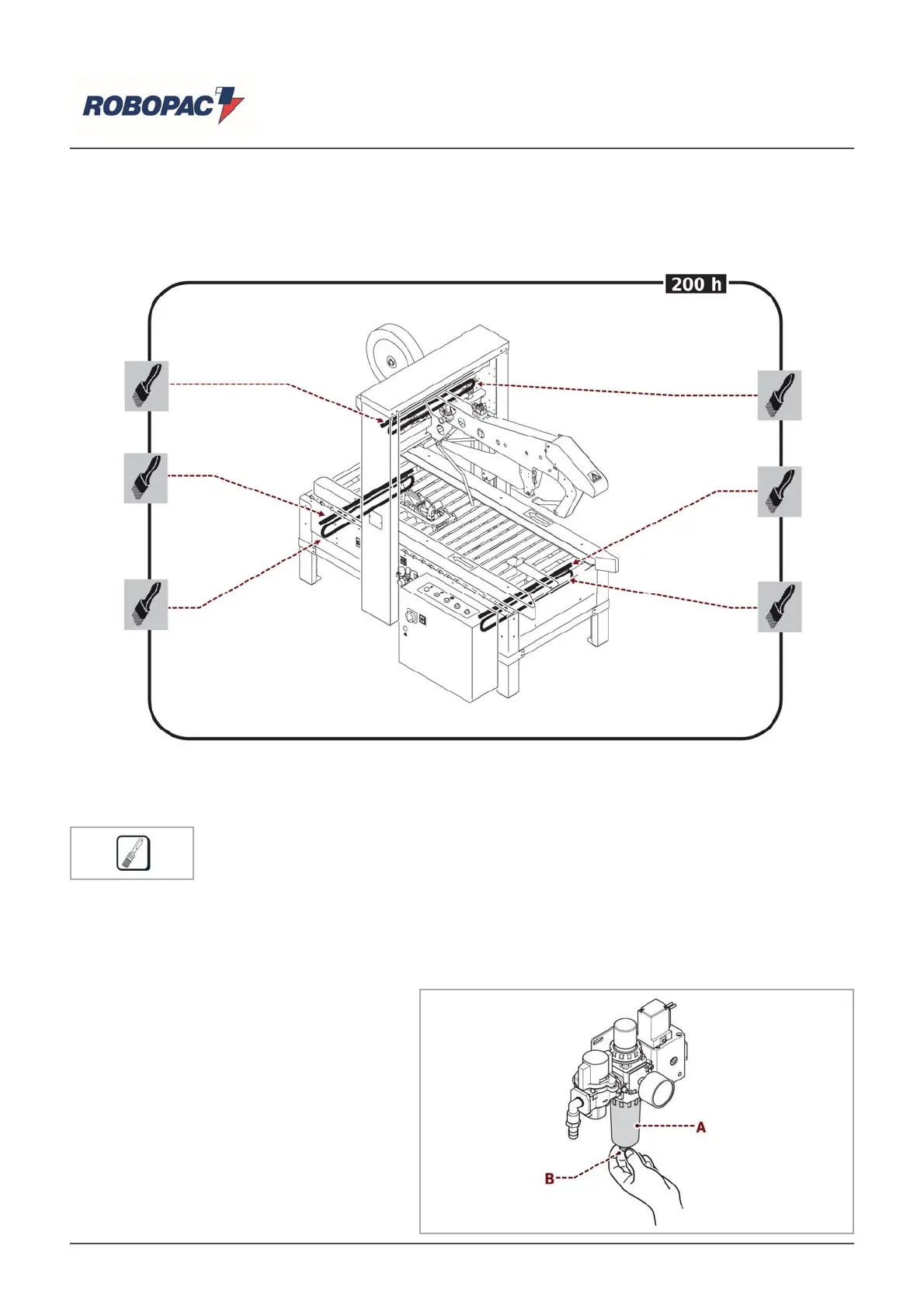

7.4. CONDENSATE DISCHARGE

Proceed as indicated.

1. Close the pneumatic supply and check

the formation of condensation in the cup

(A).

2. Push the valve (B) up until all

condensation is removed.

3. Reactivate the

neumatic su

l

.

English

Loading...

Loading...