BRP-Rotax

MAINTENANCE MANUAL LINE

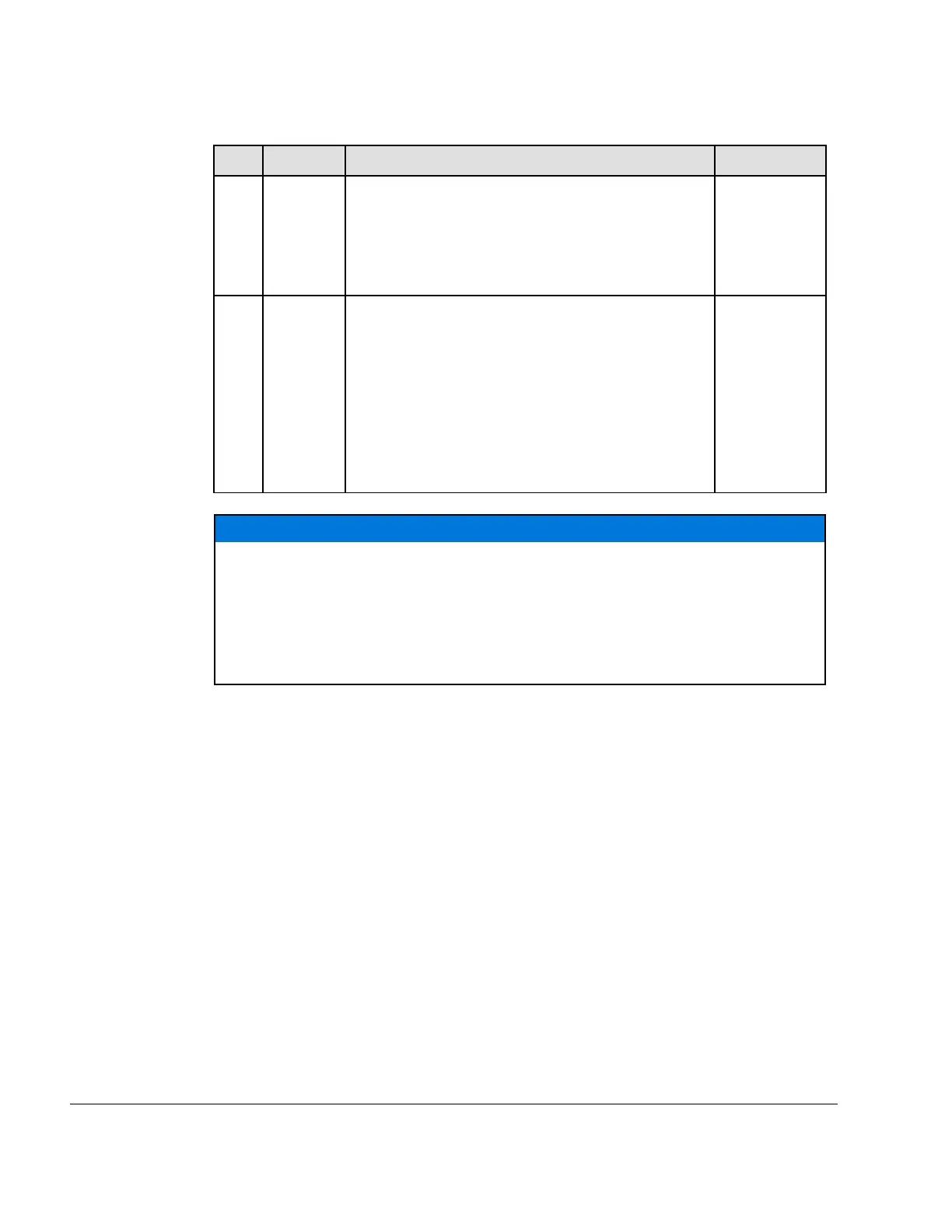

No.

part no. Description, Application Qty.

4

n.a.

Valve lapping paste

This paste, produced by various manufacturers, is a

fine granulate lapping paste for manual lapping of

valve seats and valves. The paste is usually avail-

able in 3 different granulate sizes. Use as per manu-

facturers instructions.

AR

5

n.a

Compressed air blasting using a solid blasting

agent

This method is suitable for local and gradual very

fine treatment of steel parts with rust film (propeller

shaft). The MICRONORM abrasive contains no

harmful substances, is approved by the competent

authorities and guarantees optimum cleaning. The

granulates used are of sizes 40 to 60 μ. The achiev-

able surface roughness is between 0.5 to 1μ, which

corresponds to ultrafine machining of surfaces.

AR

ATTENTION

Exhaust valves and intake valves may NOT undergo a compressed air blasting

treatment with solid blasting, strong abrasive material. Due to this surface treat-

ment one does gain a microscopic surface roughness/pitting which does allow

as a consequence the adhesion of fuel residues. These deposits are then in-

volved in a chemical reaction (especially of the sulfur and lead content of AV-

GAS) with the valve material. This effect may cause hot-gas corrosion on the

affected parts.

05–00–00

Page 10

September 01/2018

Effectivity: 912 i Series

Edition 2/Rev. 0

Loading...

Loading...