BRP-Rotax

MAINTENANCE MANUAL LINE

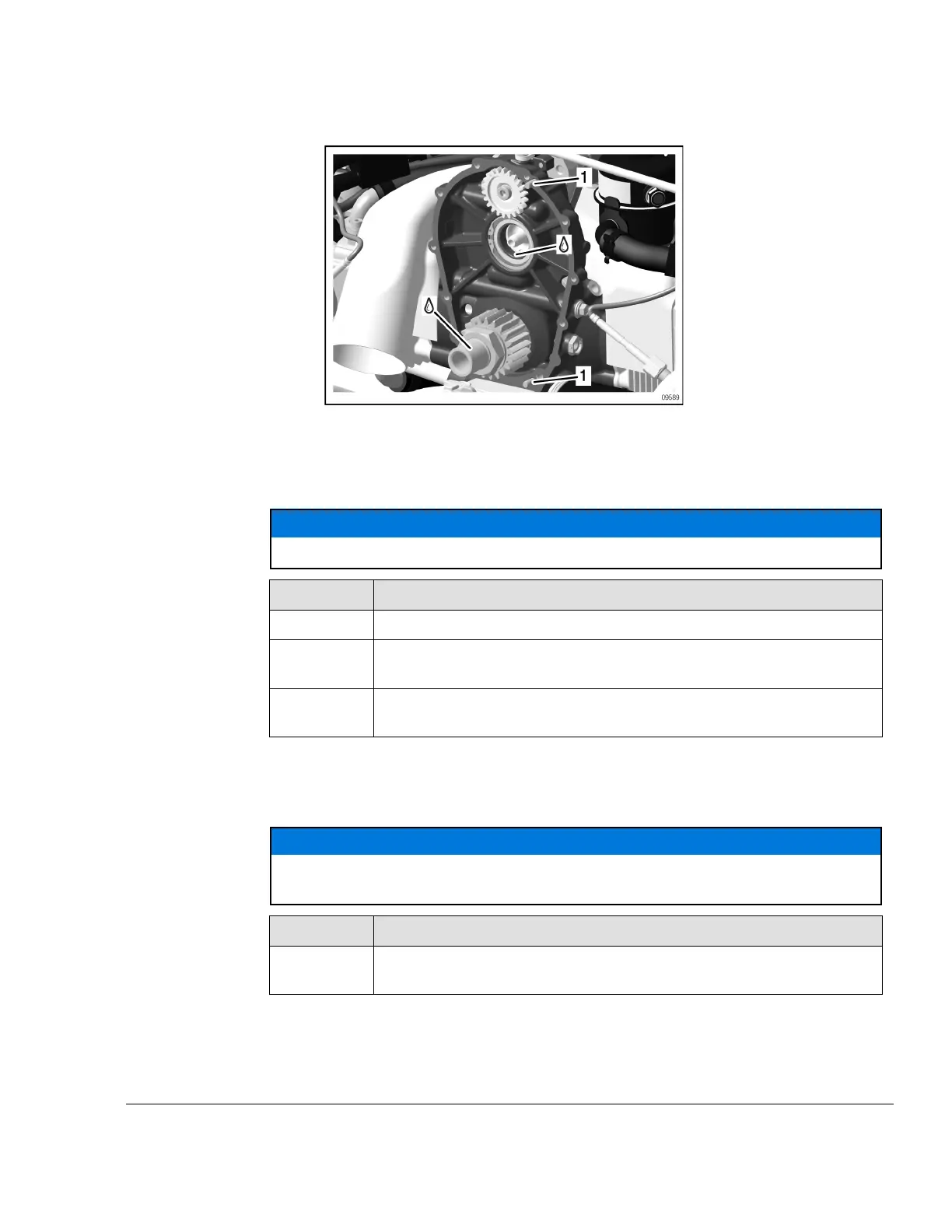

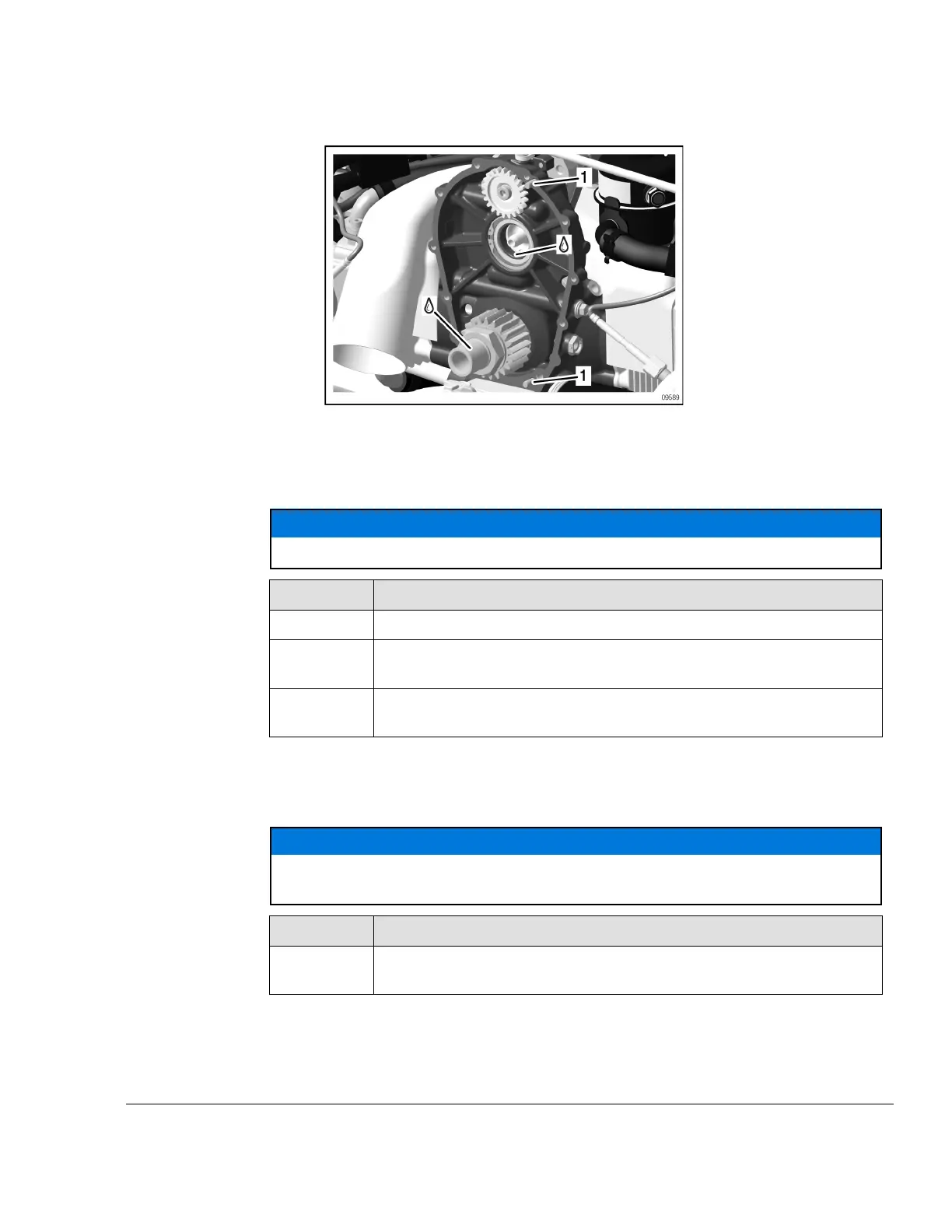

Figure 5.8

1

Dowel pins 6x20

ATTENTION

The sealing surface must be free from dirt and oil.

Step

Procedure

6

Clean both sealing surfaces with LOCTITE 7063.

7

Apply a thin layer of LOCTITE 5910 surface sealing compound to the

sealing surface of the gearbox housing.

8

Fit gearbox into position, carefully aligning crankshaft, dowels and

gears.

NOTE

Move the propeller shaft a little to allow the dog gear to engage.

ATTENTION

If excessive installation force is used, the bearing or vacuum pump gear can be

damaged.

Step

Procedure

9

Tap gently on the gearbox housing with a soft-faced hammer to position

the gearbox on the crankcase.

NOTE

If there is a large amount of resistance at a gap of approximately 10 mm, the bear-

ing rollers of the roller bearing may not be in position.

Effectivity: 912 i Series

Edition 2/Rev. 0

05–50–00

Page 9

September 01/2018

Loading...

Loading...